Method for recycling rare earth mineral from rare earth tailing with high fine grained iron mud content

A technology for the content of rare earth tailings and mud, applied in recycling technology, mechanical material recovery, solid separation, etc., can solve problems such as clogging of river channels, fine particle size of valuable components, and complex co-association relationships.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

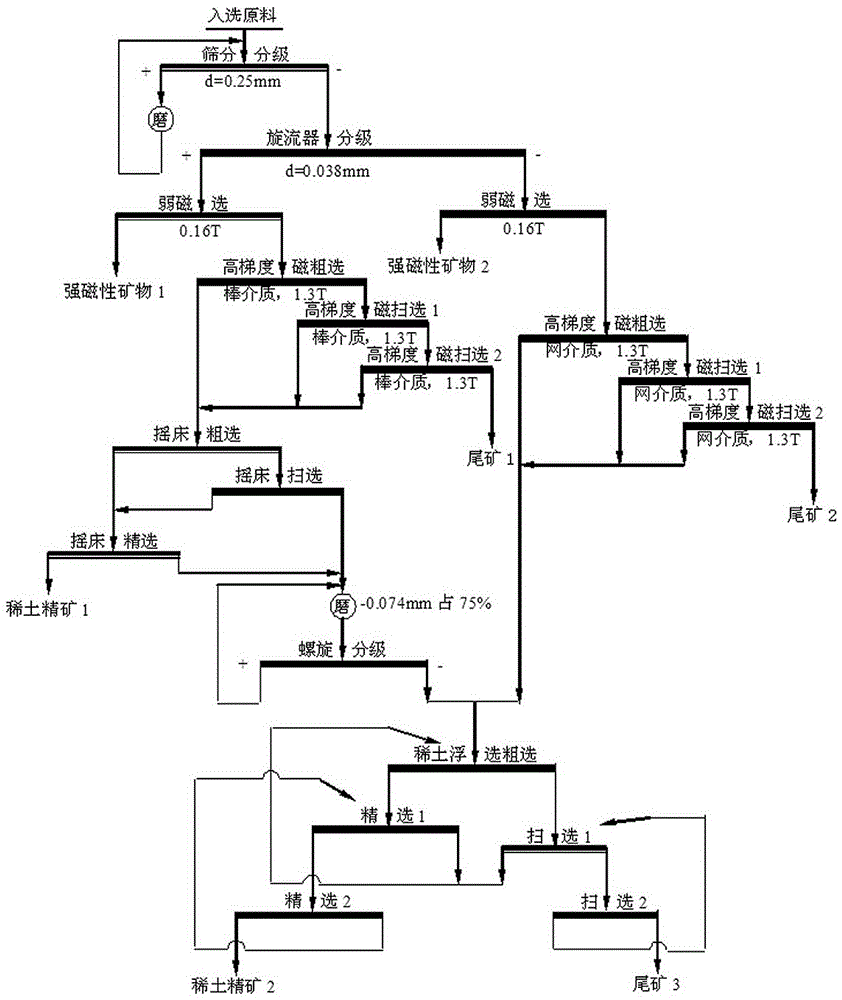

Method used

Image

Examples

Embodiment Construction

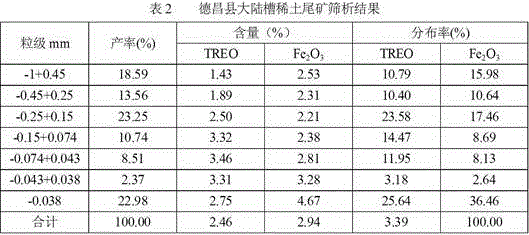

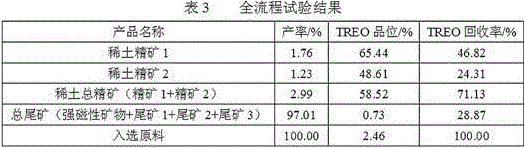

[0020] Taking Dalugou rare earth tailings in Dechang County, Liangshan Prefecture, Sichuan Province as an example, see Table 1 for multiple chemical analyzes of the sample, and Table 2 for the screening analysis results of the sample.

[0021]

[0022]

[0023] The rare earth minerals of this sample were identified as follows:

[0024] (1) -1+0.45mm particle size: bastnaesite: sporadically scattered, see monomer, see associated body with carbonate minerals, see associated body with feldspar and quartz, see barite Or the conjoined body composed of lapis lazuli, see the conjoined body composed of fluorite;

[0025] (2) -0.45+0.25mm particle size: Bastnaesite: sporadically scattered, mostly monomers, see joints with carbonate minerals, joints with feldspar and quartz, see barites A conjoined body composed of stone or lapis lazuli, see a conjoined body formed with fluorite;

[0026] (3) -0.25+0.15mm particle size: bastnaesite: sporadically scattered, mostly monomers, see a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com