3D printing method and device for manufacturing micro-fluidic chip by utilizing nanometer fiber paper base laminate

A microfluidic chip and nanofiber technology, which is applied in the directions of additive manufacturing, manufacturing tools, chemical instruments and methods, can solve the problems of difficulty in popularization and application, hidden safety hazards, and high requirements for folding accuracy, and achieves a simple, fast and economical process. The effect of manufacturing cost, simple and flexible method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

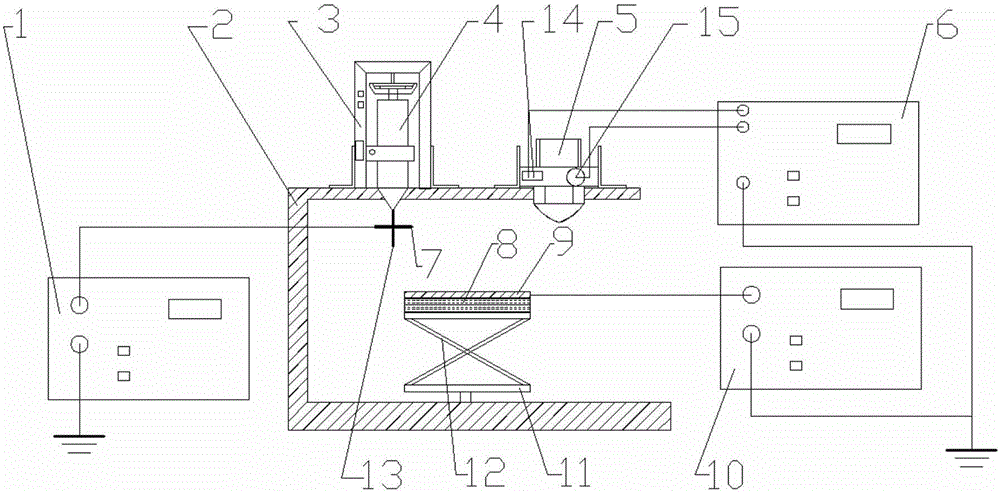

[0026] see figure 1 with 2 , the embodiment of the 3D printing device for manufacturing microfluidic chips by lamination of nanofiber paper base is provided with a DC power supply 1, a frame 2, a two-dimensional jet printing motion platform 11, a feed pump 3, a spinning needle 13, a liquid storage Syringe 4, 3D printing nozzle 5, auxiliary power supply 10, temperature control device 6, conductive substrate 7, insulating plate 8, collecting plate 9 and lifting platform 12.

[0027] The liquid storage syringe 4 is fixedly connected with the spinning needle 13, the liquid storage syringe 4 is fixed on the feed pump 3 through a clamping mechanism, and the feed pump 3 controls the supply of the polyimide solution in the liquid storage syringe 4 speed, so that the polyimide solution enters the spinning needle 13 continuously and evenly. The conductive substrate 7 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com