Method used for preparing carbon-coated Cu-doped CdS flower-shaped nano composite structure photocatalyst conveniently

A nano-composite and carbon-coated technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of high preparation cost, complex synthesis process, difficult control, etc., and achieve low product cost , good repeatability and high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh 0.7993g of cadmium chloride, 4.4mg of copper sulfate, 0.2663g of thiourea, 0.5g of glucose and 0.389g of polyvinylpyrrolidone (PVP) and dissolve them in 35mL of ethylene glycol, form a homogeneous solution by ultrasonic dispersion, and then stir for 20 minutes , stop stirring. Put the mixed solution obtained above into a 50mL reaction kettle, react at 160°C for 11 hours, take the suspension, wash it by centrifugation, and dry it at 60°C. The sample label is C-Cu0.5%Cd99.5%S.

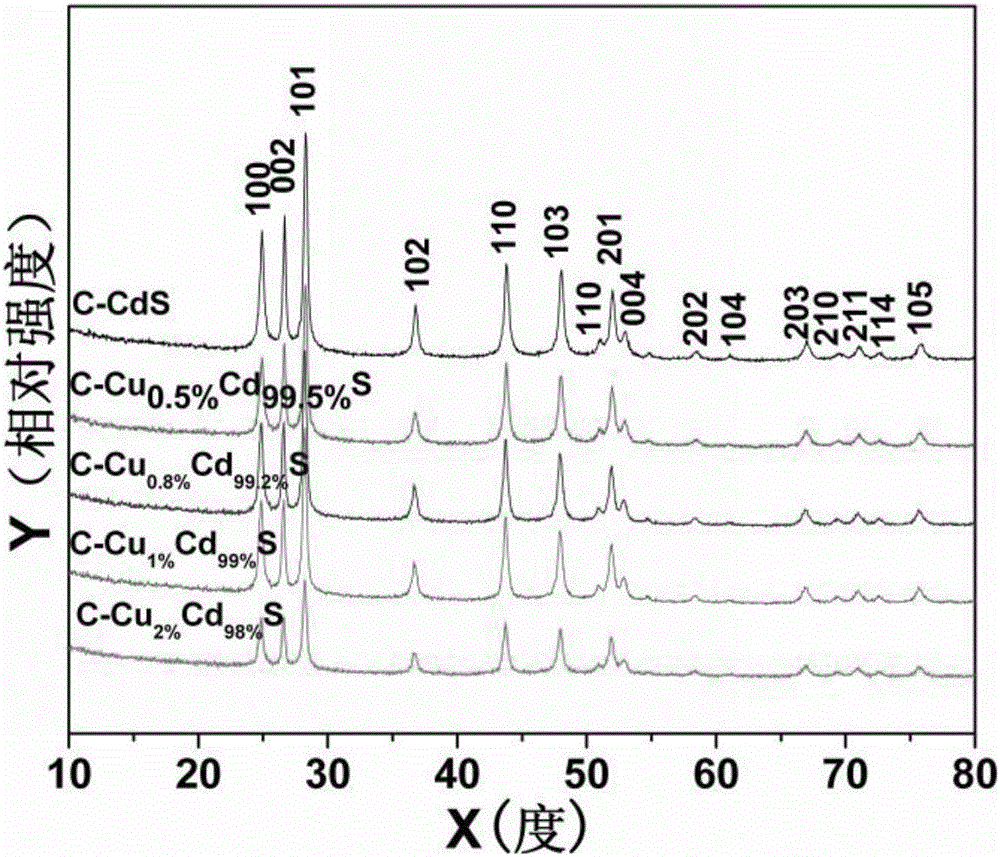

[0021] Do X-ray diffraction analysis for the CdS flower-like nanocomposite structures coated with different Cu doping amounts prepared in all examples, the results are as follows figure 1 As shown, its abscissa X is the diffraction angle (2θ), and the ordinate Y is the relative diffraction intensity; figure 1 XRD patterns of CdS flower-like nanocomposite structure samples coated with medium carbon with different Cu doping amounts, all diffraction peaks correspond to lattice constants and ...

Embodiment 2

[0024] Weigh 0.7993g of cadmium chloride, 7.1mg of copper sulfate, 0.2663g of thiourea, 0.5g of glucose and 0.389g of polyvinylpyrrolidone (PVP) and dissolve them in 35mL of ethylene glycol, form a homogeneous solution by ultrasonic dispersion, and then stir for 20 minutes , stop stirring. Put the mixed solution obtained above into a 50mL reaction kettle, react at 170°C for 8 hours, take the suspension, wash it by centrifugation, and dry it at 60°C. The sample label is C-Cu0.8%Cd99.2%S.

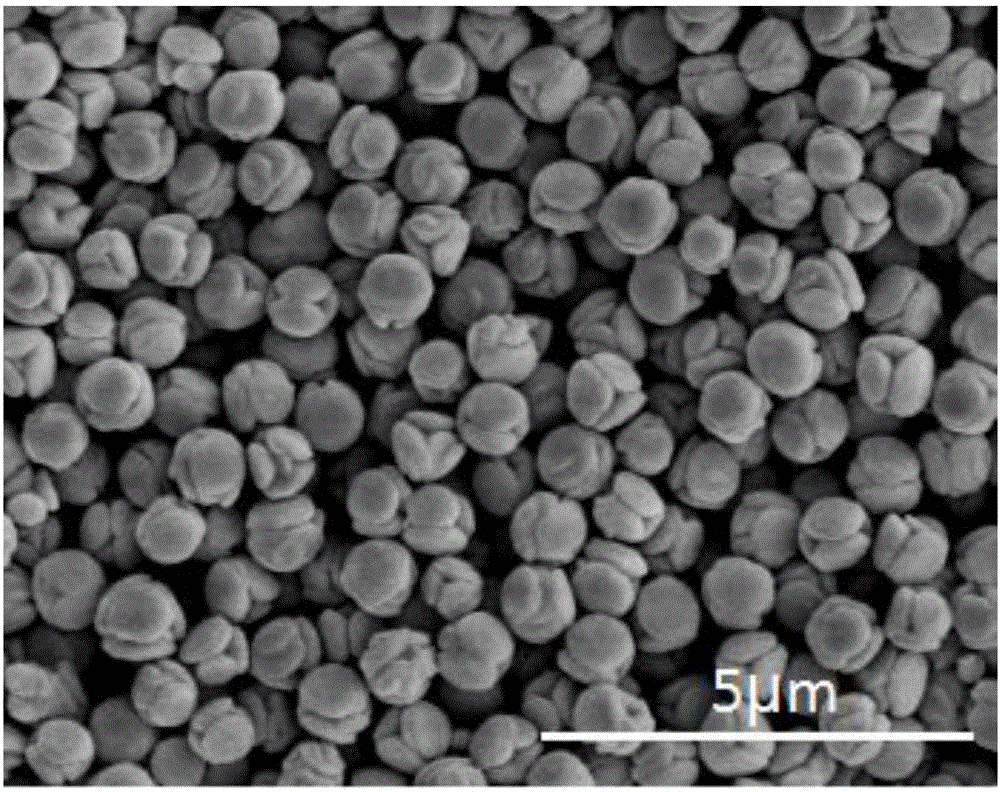

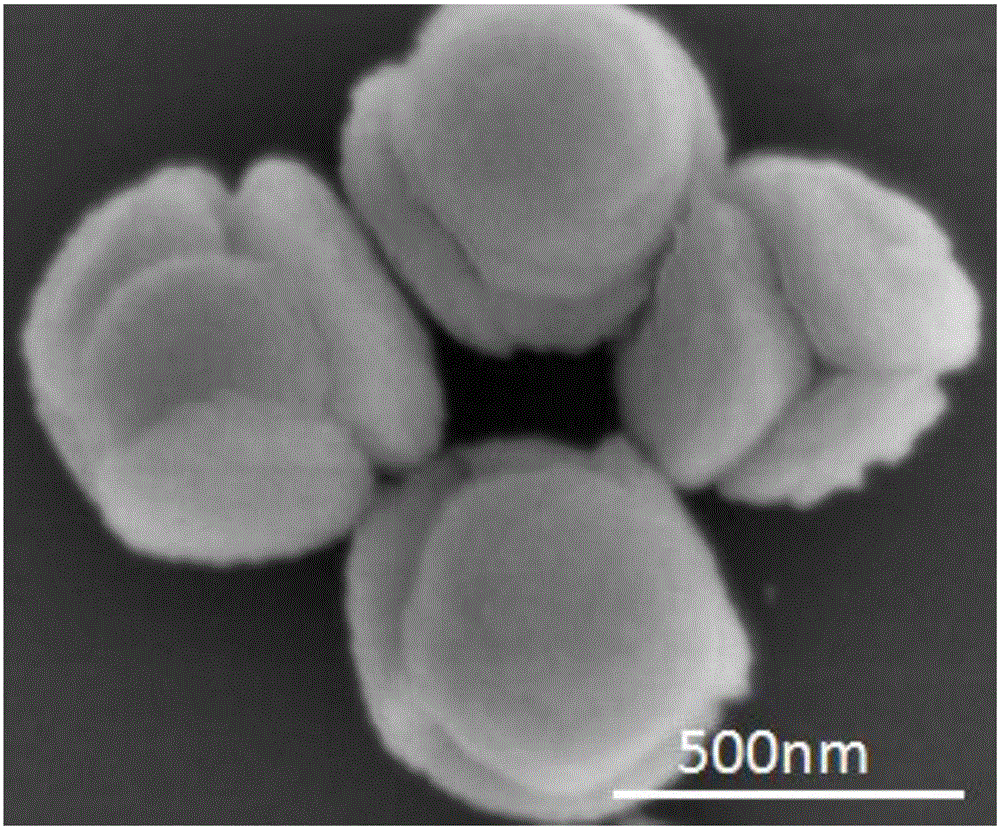

[0025] For the sample C-Cu0.8%Cd992%S core-shell nanospheres prepared in this embodiment, the field emission scanning electron microscope analysis is done, and the electron microscope photos obtained are as follows image 3 As shown, it can be seen that the product can be seen that the output of the carbon-coated Cu-doped CdS flower-like nanocomposite structure photocatalyst is large, the size is uniform, and the diameter is about 350nm.

[0026] For the C-Cu0.8%Cd99.2%S flower-like nano-com...

Embodiment 3

[0028] Weigh 0.7993g of cadmium chloride, 8.8mg of copper sulfate, 0.2663g of thiourea, 0.5g of glucose and 0.389g of polyvinylpyrrolidone (PVP) and dissolve them in 35mL of ethylene glycol, form a homogeneous solution by ultrasonic dispersion, and then stir for 20 minutes , stop stirring. Put the mixed solution obtained above into a 50mL reaction kettle, react at 180°C for 7 hours, take the suspension, wash it by centrifugation, and dry it at 60°C. The sample number is C-Cu1%Cd99%S.

[0029] For the C-Cu1%Cd99%S flower-shaped nano-composite structure photocatalyst prepared in this example is analyzed by X-ray photoelectron spectrometer (XPS), the results are as follows Figure 6 As shown, the abscissa X is the binding energy (eV), and the ordinate Y is the relative diffraction intensity. It can be seen that the C-Cu1%Cd99%S flower-like nanocomposite structure photocatalyst prepared in this example has Cu, Cd, S, and C four elements.

[0030] For samples with different Cu do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com