High-shear baffled reactor

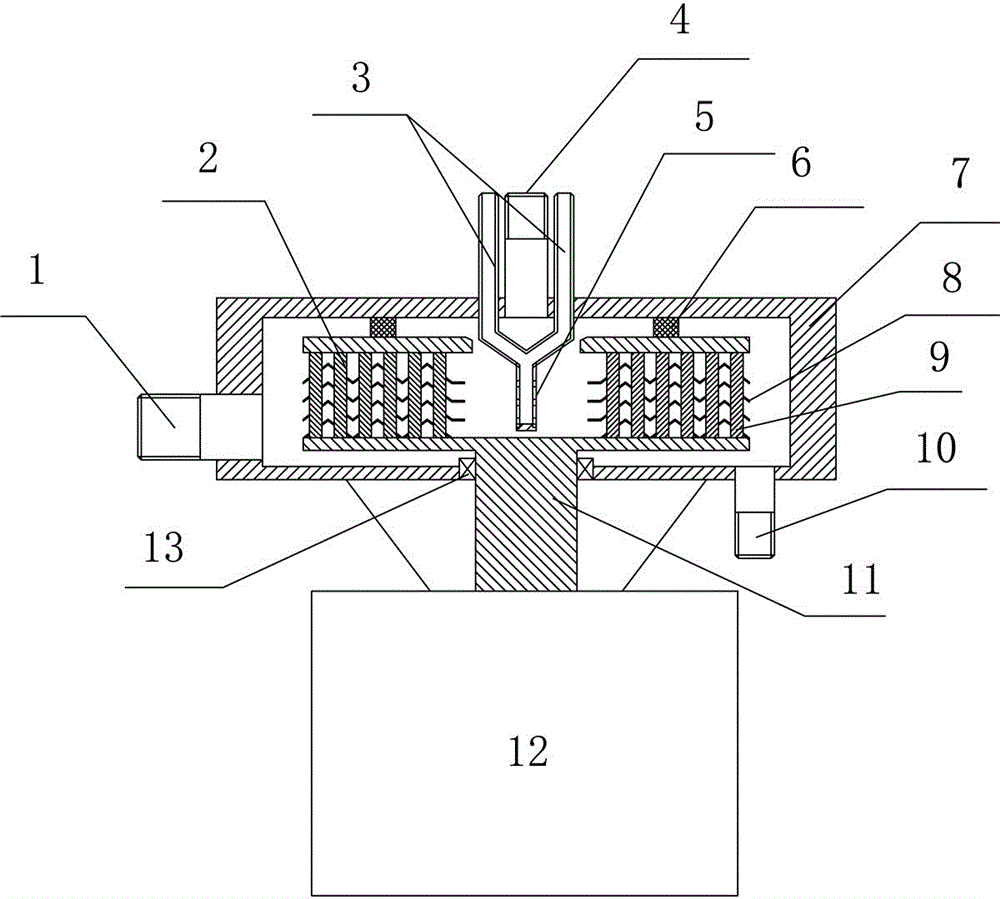

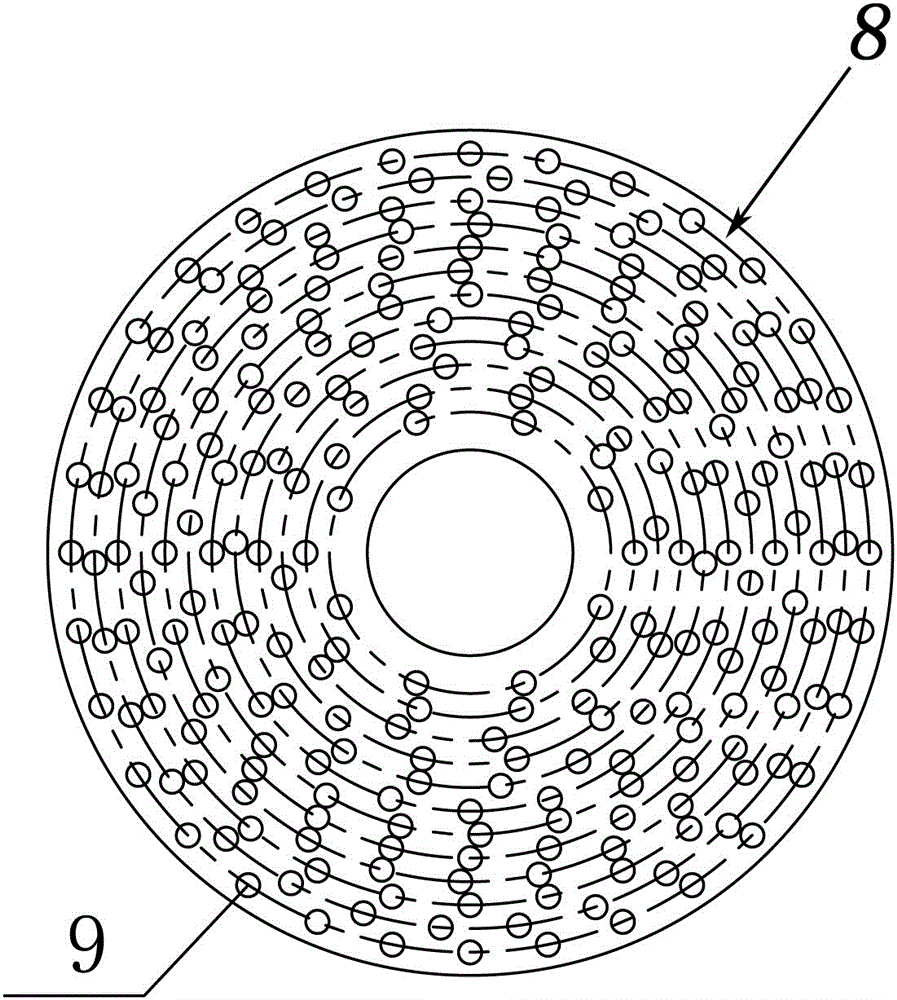

A baffled reactor, high shear technology, applied in the reaction of liquid and gas under the catalytic active body, the chemical method of reacting liquid and gas medium, chemical instruments and methods, etc. Uneven distribution in the axial and circumferential directions, short residence time, etc., to achieve the effect of rapid mass transfer, increase reaction rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0038] Example 2: Vacuum water deoxygenation in a high shear baffle reactor

[0039] Water enters from the liquid inlet port 3 on a high-shear baffle reactor, and enters the inner cavity of the reactor through the liquid uniform distribution port 5. Radial outward flow; the vacuum pump gas outlet is connected to the reactor gas outlet 4. Under the action of the vacuum pump, the oxygen desorbed from the water flows radially inward in the rotating body 2 under the action of the pressure gradient, passing through the center of the reactor and the gas The outlet 4 is sucked out, and the liquid is discharged from the liquid outlet 10. The test conditions are: vacuum degree 0.096 MPa, liquid volume 600 L / h, rotation speed 800 rpm, temperature 26°C, initial oxygen content of water 8.3 ppm, water content after deoxidation by this process Oxygen down to 20 ppb.

Embodiment 3

[0040] Example 3: Methyldiethanolamine in a high shear baffle reactor removes CO from natural gas 2

[0041] Natural gas enters the equipment from the gas inlet 1 pipe of a high-shear baffle reactor, and flows from the outer edge to the inner edge of the rotating body 2 under pressure, and the methyldiethanolamine absorption liquid enters the reactor from the liquid distributor on the upper part of the reactor Inside, and flow from the inner edge of the rotating body 2 to the outer edge. Absorption liquid and natural gas countercurrently contact and react in the rotating body 2 to absorb CO 2 . After the reaction, the natural gas is discharged from the gas outlet 4, and the absorption liquid is discharged from the liquid outlet 10. Test conditions: natural gas flow rate 20000 m 3 / h, MDEA absorption liquid flow rate 200 m 3 / h, speed 150 rpm, temperature 40 ℃, pressure 70 atm, imported CO 2 Concentration 3%, export CO 2 The concentration is 0.3%.

Embodiment 4

[0042] Example 4: Degradation of phenol by ozone oxidation in a high shear baffle reactor

[0043] Ozone gas enters the equipment from the gas inlet 1 of a high-shear baffle reactor, and flows along the outer edge of the rotating body 2 to the inner edge under the push of pressure, and the phenol-containing wastewater enters the interior of the reactor from the liquid distributor on the upper part of the reactor, and Flow from the inner edge of the rotating body 2 to the outer edge. Ozone gas and phenol waste water contact and react countercurrently inside the rotating body 2 to degrade phenol. After the reaction, the gas is discharged from the gas outlet 4, and the waste water is discharged from the liquid outlet 10. Test conditions: ozone gas flow rate 1 m 3 / h, ozone content 60 mg / m 3 , the phenol concentration is 100 mg / L, the liquid flow rate is 100 L / h, the rotation speed is 1000 rpm, and the phenol degradation rate is 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com