Online detecting device and detecting method for integrity of hollow fiber membrane module

A detection device and fiber membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of large interference of human factors, cumbersome method steps, difficult on-line detection, etc., and achieve strong monochromaticity. , improve sensitivity, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

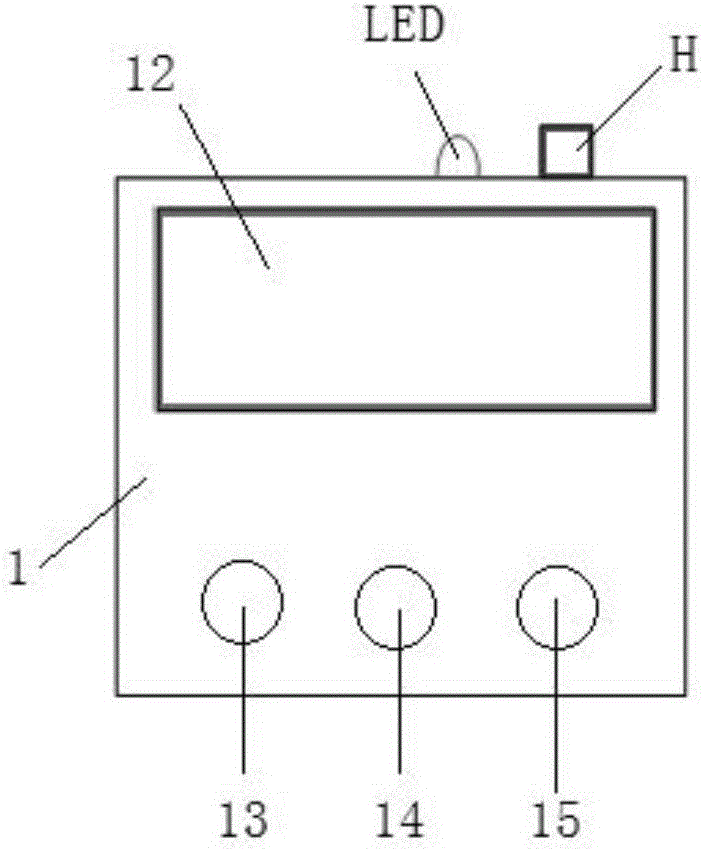

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

[0038] An online detection device for the integrity of a hollow fiber membrane module of the present invention, such as Figures 1 to 5As shown, it includes a light-shielding housing 1 provided with a water inlet 2 and a water outlet 3, and the light-shielding housing 1 is provided with a laser emitting system, an optical detection system, a laser receiving system 10 and a display alarm system, and the light-shielding housing 1 is set as Black to avoid interference from external light sources.

[0039] The laser emitting system includes a first laser emitter 4 and a second laser emitter 5 arranged side by side on the inner wall of the light-shielding housing 1, both of which have a laser wavelength of 650nm and can be independently controlled and operated.

[0040] The optical detection system includes a first optical detector 6 and a second optical detector 7 arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com