Blowing and inhaling type welding fume dust removal system

A technology of dust removal system and welding fume, which is applied in the direction of gas treatment, separation of dispersed particles, chemical instruments and methods, etc. It can solve the problems of inability to completely solve the problem of dust removal, small particle size of welding fume, high one-time investment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

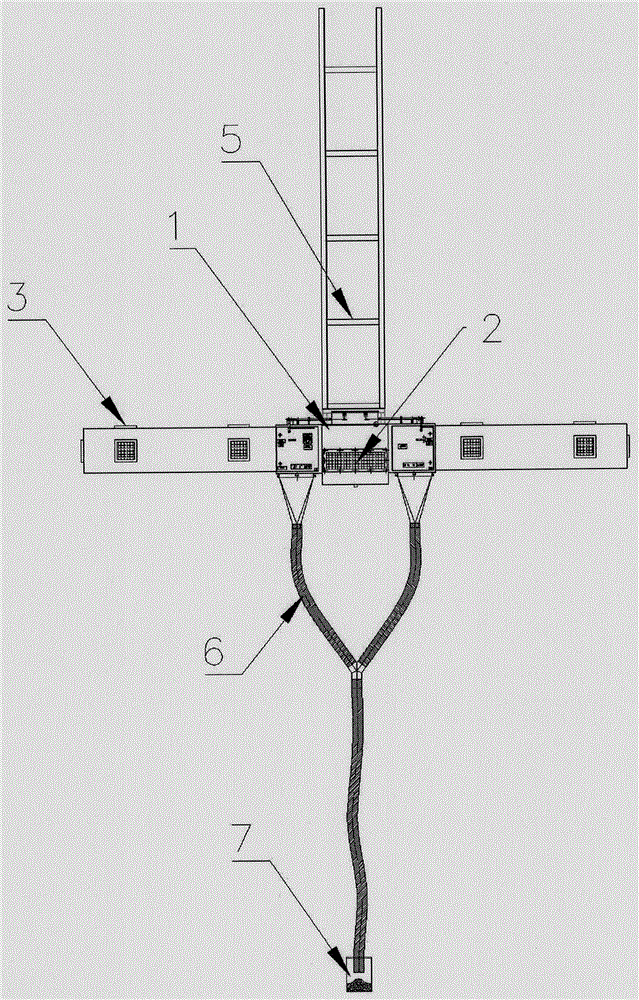

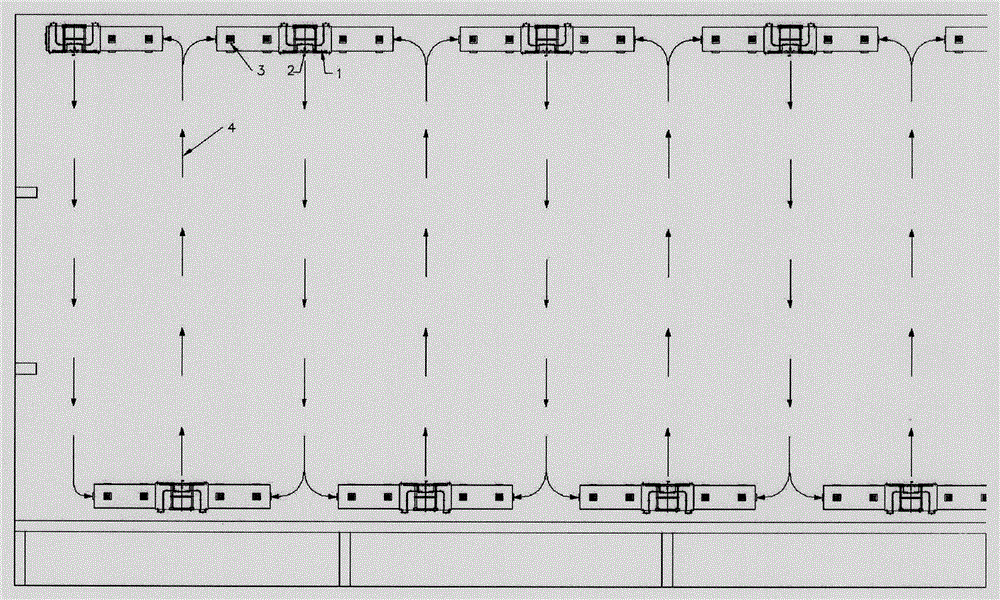

[0011] Referring to the accompanying drawings, the blowing and suction welding fume dust removal system includes a dust collector 1, a blowing port 2, a suction port 3, a jet 4, a hanging bracket 5, a hose 6, and an ash hopper 7; The suction type welding fume dust removal system is characterized in that at a certain height of the factory building, multiple air outlets 2 and suction outlets 3 are arranged in a W-shaped row on both sides, and the air is injected into a large space through the air outlets 2 to form a staggered direction with the same forward direction. Multiple parallel jets 4; after reaching a certain distance, each jet merges with the suction flow to form a fixed airflow path, so that the jet can only develop in the longitudinal direction, so the movement of the jet in this area is similar to the plane movement, forming a horizontal Air barrier; due to the large space of the factory building and the large number of air outlets arranged, after the jets 4 converge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com