Automatic wet dust removal system

A technology of wet dedusting and dedusting cylinders, which is applied in chemical instruments and methods, sterilization/microdynamic water/sewage treatment, water treatment parameter control, etc., can solve the problems of waste of water resources, production cost, large amount of sewage, etc., and achieve rapid The effect of removal, low input cost and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

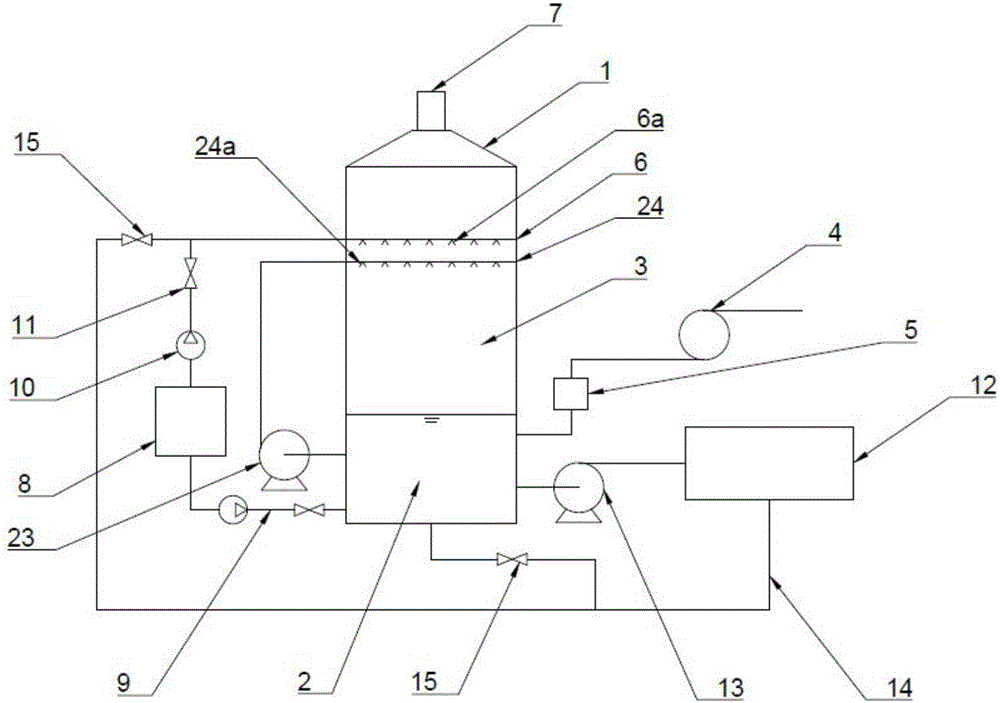

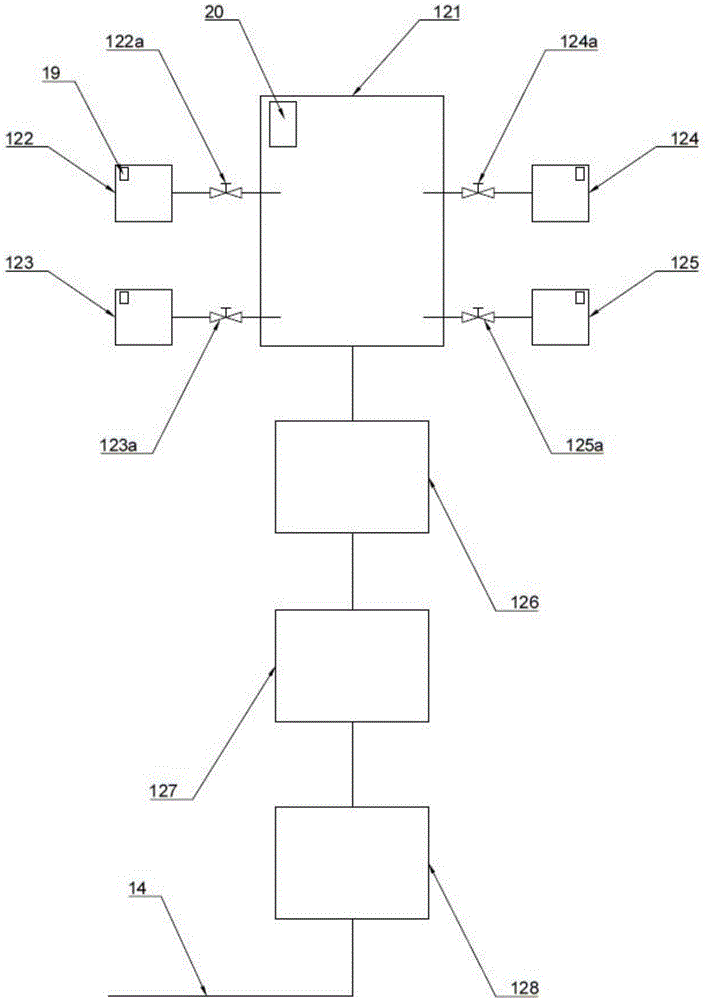

[0022] The best implementation mode of the present invention will be described below with reference to the accompanying drawings.

[0023] Such as Figures 1 to 3 As shown, a kind of automatic wet dedusting system of the present invention comprises dedusting cylinder 1, and the lower part of dedusting cylinder 1 is dedusting water tank 2, and dedusting water tank 2 is provided with air inlet, and the air inlet is installed on the air inlet that sucks the dust-containing gas into the dedusting cylinder. The high-pressure centrifugal fan 4 is equipped with an air volume sensor 5 for real-time detection of its air intake on the air inlet; the upper part of the dust removal cylinder 1 is a dust removal chamber 3, and a spray dust collector 6 is installed on the inner upper part of the dust removal chamber 3. The spray dust collector 6 includes A plurality of electric nozzles 6a arranged in the circumferential direction, and a plurality of electric nozzles 6a are installed on the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com