Liquid distributor for falling-film evaporator

A technology of liquid distribution device and falling film evaporator, which is applied in the direction of evaporator liquid feeder, vertical tube evaporator, evaporation, etc., can solve the problems of easy deviation of liquid materials, splashing into heating pipes, local dry walls, etc., and achieve The equipment design is less difficult, the liquid is evenly distributed, and the effect of stable film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

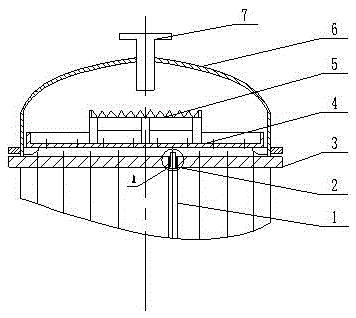

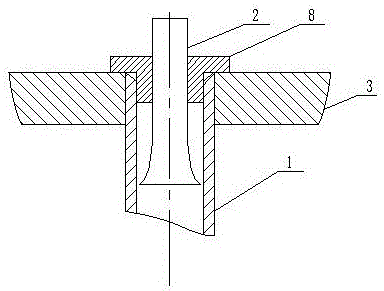

[0022] A liquid distribution device for a falling film evaporator, comprising a heating tube 1 , a tube plate 3 , a distribution plate 4 , a dispersion plate 5 , a head 6 and a feeding tube 7 , and a drainage tube 2 is inserted into the upper part of the heating tube 1 .

[0023] Further, the lower part of the drainage tube 2 is trumpet-shaped.

[0024] Further, the drainage tube 2 is coaxial with the heating tube 1, and there is a gap between the outer wall of the drainage tube 2 and the inner wall of the heating tube 1. When the feed liquid flows down the inner wall of the drainage tube, it flows to the heating tube wall due to the diversion effect of the horn-shaped part. Finally, the feed liquid flows down in the form of a film on the inner wall of the heating tube.

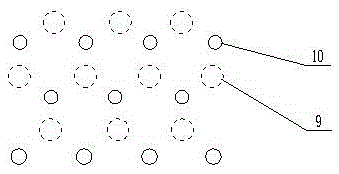

[0025] Further, the heating tubes 1 on the tube sheet 3 are distributed in an equilateral triangle.

[0026] Further, the diameter of the hole in the distribution disk 4 is 3-6 mm. If the pore size is too s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com