Silage whole-plant harvest and silage ear stem harvest inclusive type corn machine

A compatible corn machine technology, applied to harvesters, agricultural machinery and tools, threshing equipment, etc., can solve problems such as short operation time, blockage of ear picking road, and small row spacing of corn plants, so as to increase extra income and work time The effect of extension and user income increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

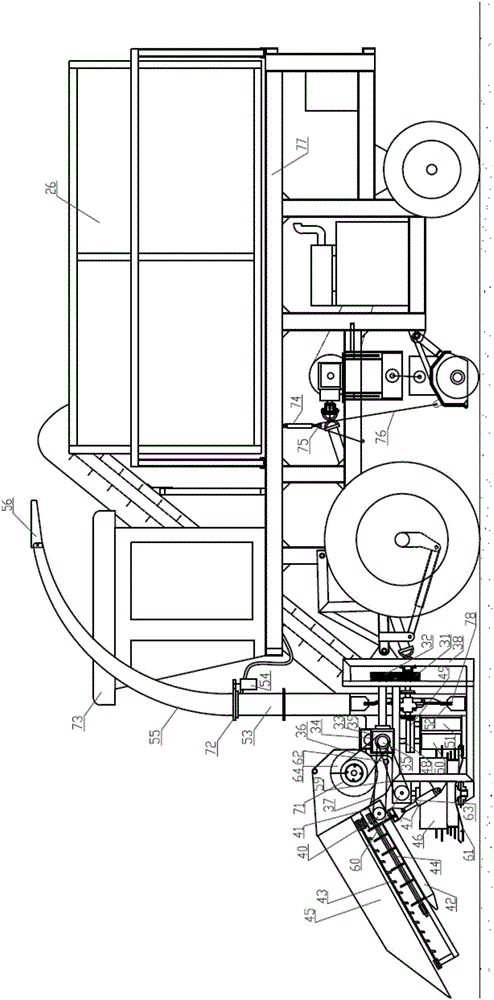

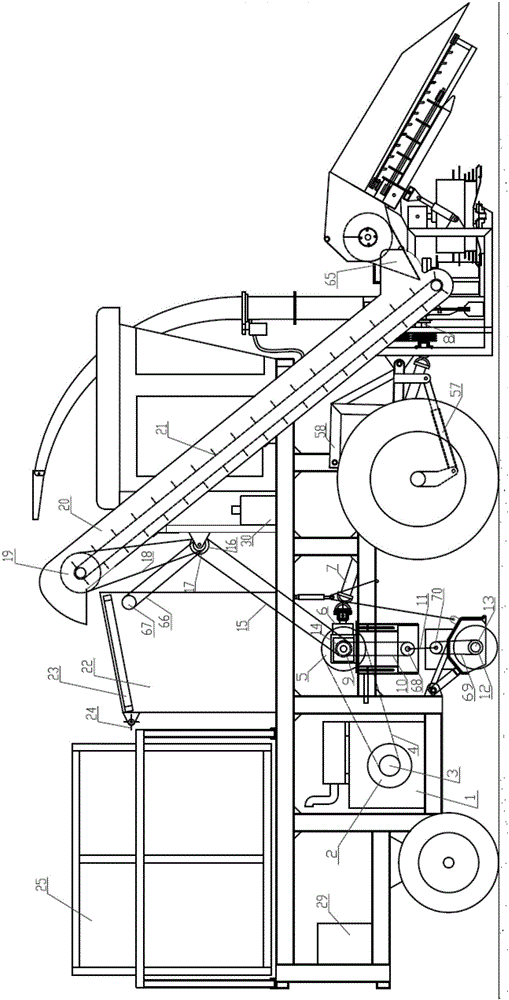

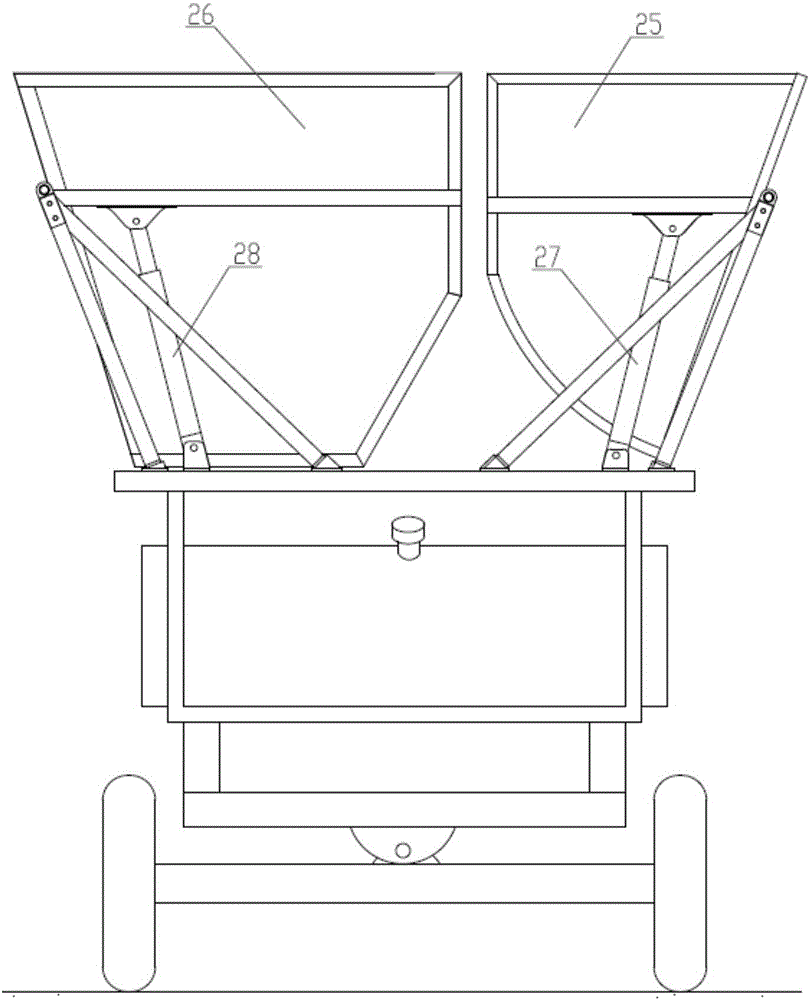

[0031] Such as figure 1 and figure 2 As shown, the corn machine compatible with both silage harvesting and silage ear stem harvesting includes a frame 77, a header harvesting part, an ear elevator part, a field returning device part, a peeling machine part, a power part, and an ear collection part. Box 25 and straw collection box 26, header harvesting part, ear elevator part, returner part, peeling machine part, ear collection box and straw collection box are all arranged on the frame, and header harvesting part is arranged on the frame The front part of the frame, the field return part is set at the bottom of the frame, the bottom end of the ear elevator part is connected with the header harvesting part, the top part of the ear elevator part is connected with the peeler part, and the ear collection box is located in the peeler part the rear. Fruit ear collection box and stalk collection box are all arranged on the rear portion of frame 77.

[0032] Described power part co...

Embodiment 2

[0050] The difference with embodiment 1 is: as Figure 4 As shown, the ear picking system of the header part is dismantled. At this time, the harvester is used to harvest the whole silage plant. The harvesting process is as follows: the straw feeding drum 46 touches the whole corn plant during the operation of the harvester, and the corn plant The root of the corn plant is cut off by the cutter head 61 at the bottom of the drum, and the corn plant with the cut root is pinched into the toothed roller 50 by two stalk feeding rollers 46 rotating in opposite directions. Because the gap between the two rollers of the toothed roller is small, it can be more The corn plant is clamped and sent back to the pre-pressing roller 51. The gap between the two rollers of the pre-pressing roller is very small, and the corn stalks and corn ears can be flattened and then sent to the mower 52. After the corn stalks and corn ears are pulverized synchronously, the cutter impeller 78 blows the chopp...

Embodiment 3

[0054] The difference from Example 1 is that the ear picking system includes a header shield, a reel chain, an ear chain, at least one set of stalk rollers, at least one set of ear picking plates, a stalk puller gear box, and an ear conveying agitator. At the Longhe fruit ear discharge port, a set of ear picking plates with a fixed gap is arranged on the upper end of each set of stem pulling rollers. The two stem pulling rollers rotate at high speed in opposite directions to quickly pull down the corn plant. During the pulling process, the corn ears touch the picking plate. The ear boards are removed after the ears, while the corn stalks continue to be pulled down into the straw feeding system.

[0055] Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com