Grabbing Chinese yam seeder

A technology of seeder and yam, applied in the directions of planting method, application, excavation/covering of trenches, etc., can solve the problems of restricting the large-scale production and development of yam, unable to completely liberate labor force, and unable to realize automation, etc., to reduce labor The effect of burden, simple structure and high power transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

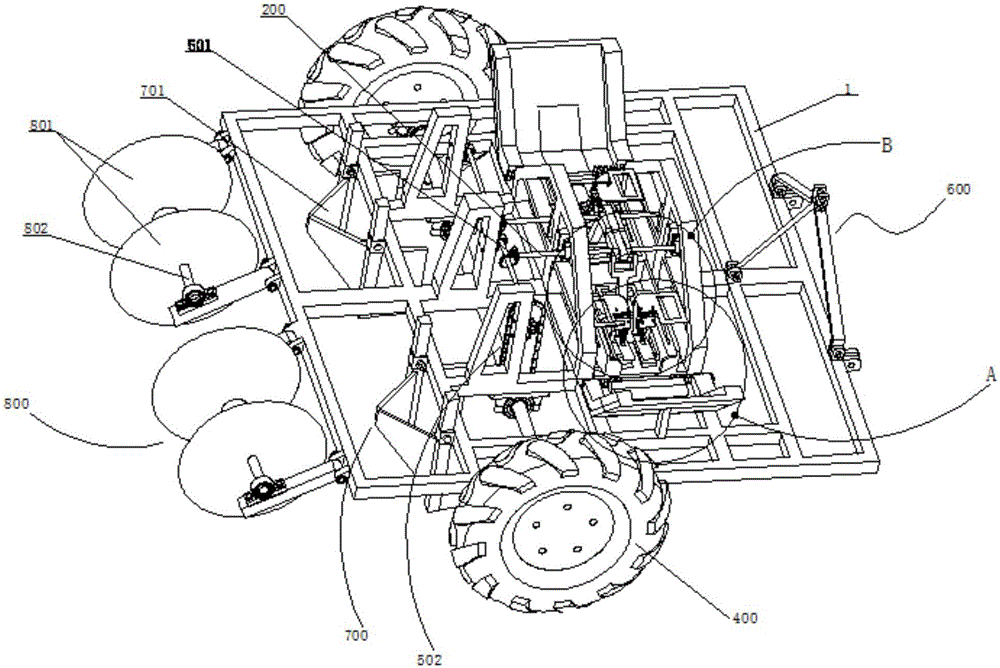

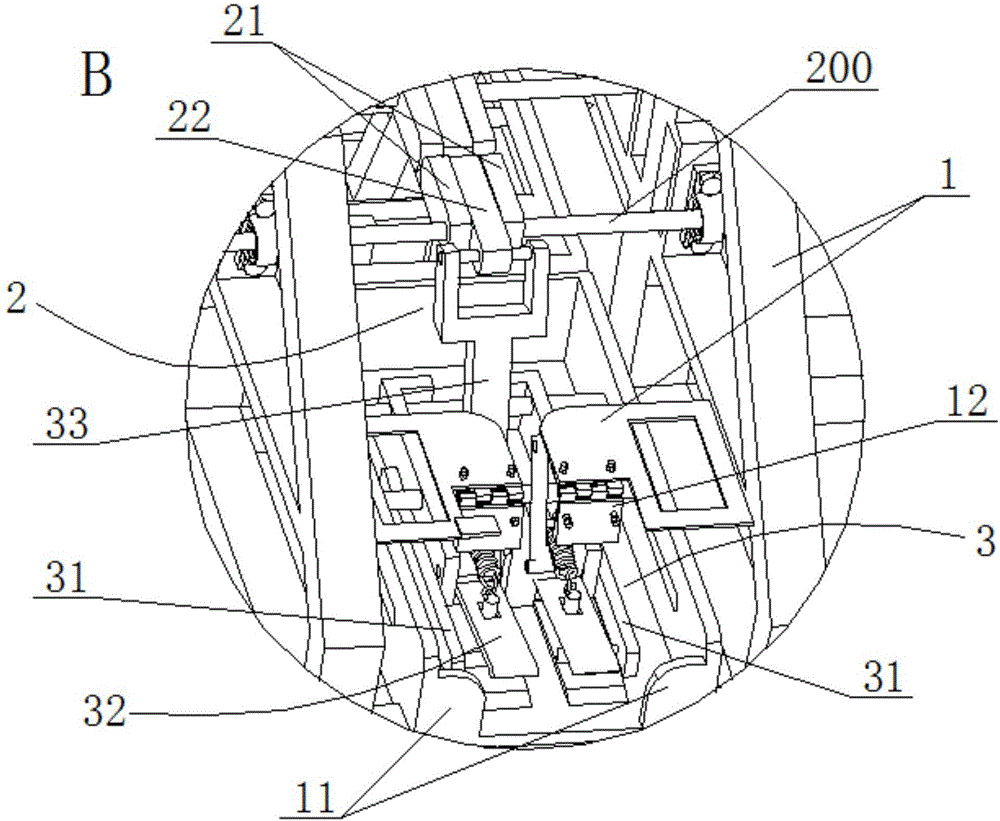

[0025] Such as Figure 1 to Figure 5 As shown, a grab type yam seeder of this embodiment includes a seeding device 100, which is installed on the frame 1, and the seeding device includes a crank linkage mechanism 2 and a mechanical arm 3, and the crank is connected to The crank 21 in the rod mechanism 2 is rotatably connected to the output shaft 200, and the connecting rod 22 is connected with the mechanical arm 3; The connecting rod 22 in the crank linkage mechanism is hinged, and the other end is fixedly connected with the grabbing arm 32 and drives the grabbing arm 32 to slide in the slideway 31; Baffle plate 11 of rack 1.

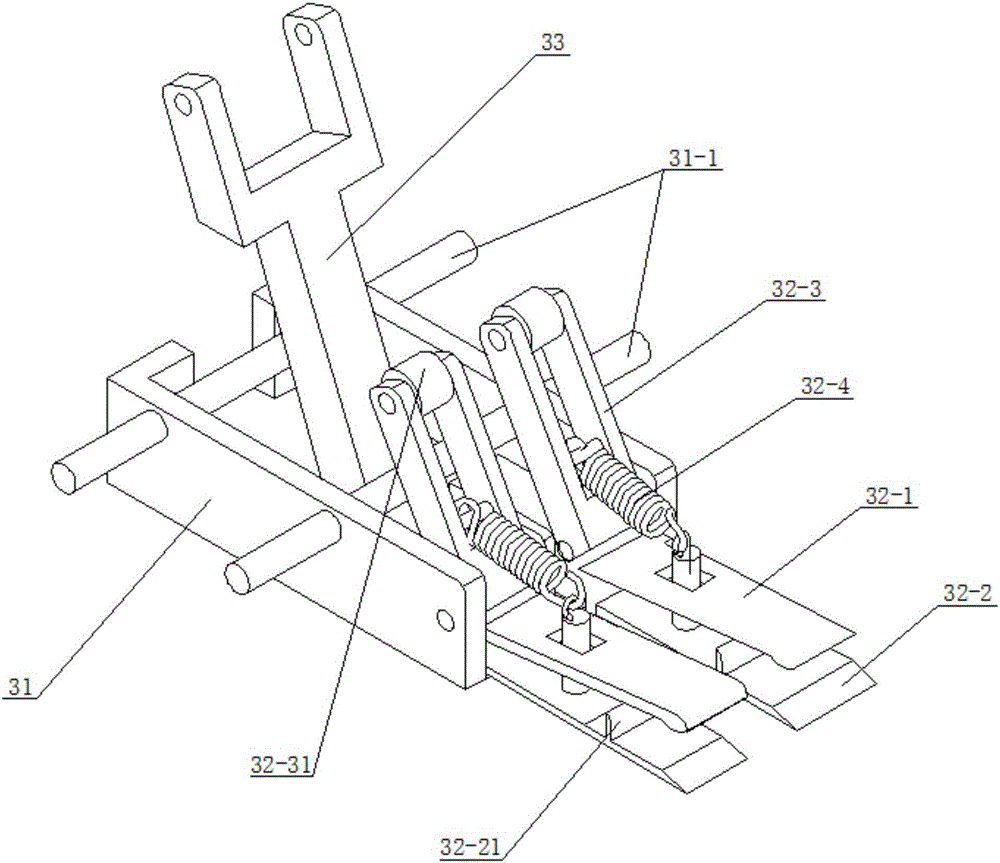

[0026] A specific structure of the grab arm is enumerated below: the grab arm includes an upper splint 32-1, a lower splint 32-2, a support frame 32-3 and a spring 32-4, and the upper splint 32-1 and the support frame 32-3 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com