Construction method of impacting and rolling

A technology of impact rolling and construction method, applied in basic structure engineering, soil protection, construction and other directions, can solve the problems of high project cost and low efficiency, and achieve the goal of reducing project cost, improving project quality and reducing the number of rolling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

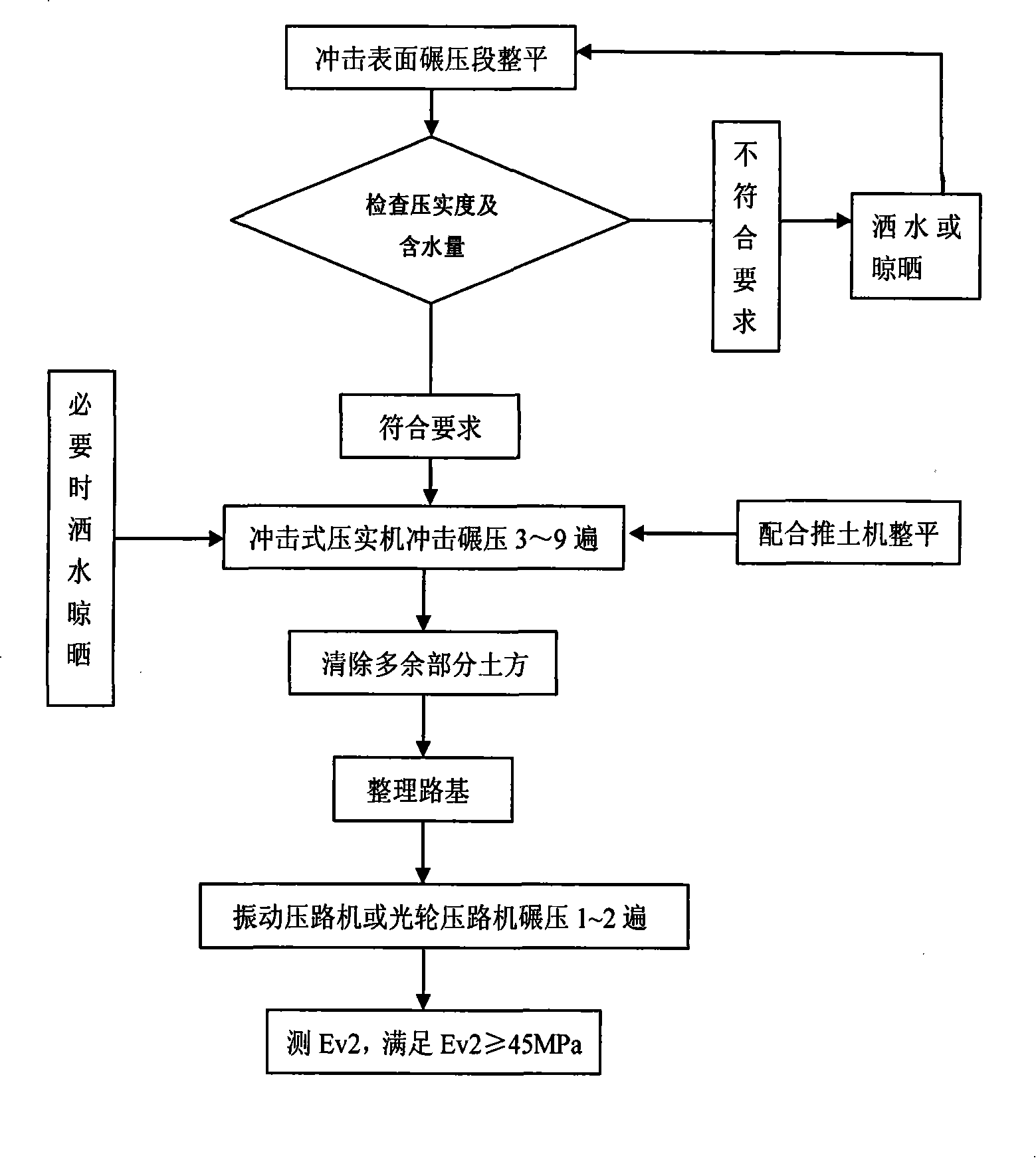

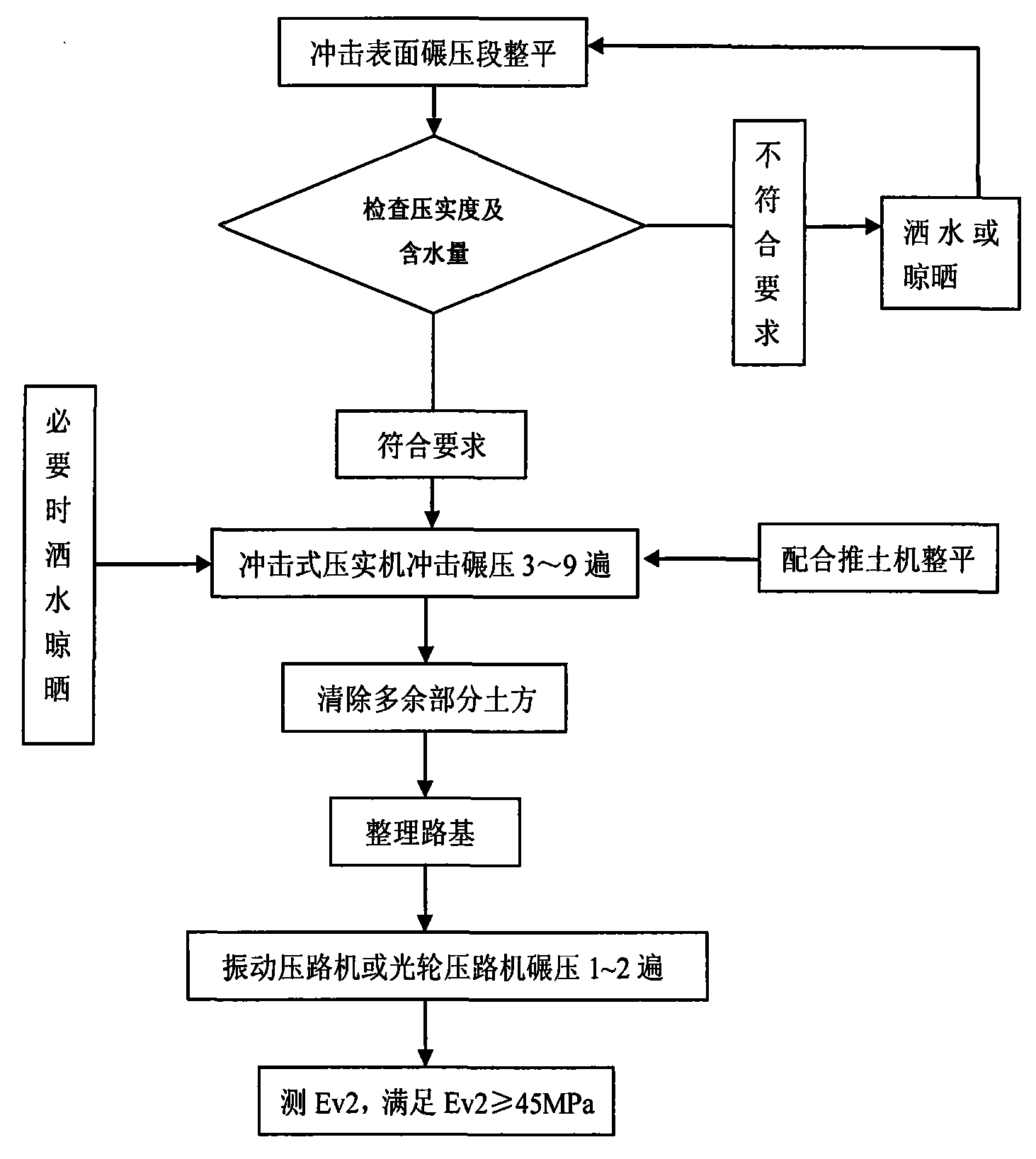

[0037] As shown in the accompanying drawings, a construction method of impact rolling includes the following process steps:

[0038] A. The surface of the impact rolling section is leveled, and the degree of compaction and water content are checked to see if they meet the design requirements. If they do not meet the design requirements, water or dry them;

[0039] B. When the compactness and water content of the surface of the impact rolling section meet the design requirements, use an impact compactor to impact and roll 3 to 9 times, and at the same time use a bulldozer to level it;

[0040] C. Remove excess earthwork and tidy up the roadbed;

[0041] D. Use a vibratory roller or smooth wheel roller to roll 1 to 2 times;

[0042] E. Detect the secondary deformation modulus Ev2 value of the foundation soil after impact rolling, and meet the requirements of Ev2≥45MPa.

Embodiment 2

[0044] A construction method of impact rolling, comprising the following process steps:

[0045] First, the soil sample analysis is carried out, and the impact compaction method can be used if the following conditions are met, namely:

[0046] (1) Detection of water content refers to the detection of water content at a depth of 20 cm below the surface of impact rolling, and the water content is ≤ 60%;

[0047] (2) The impact rolling section is coarse-grained soil such as sandy soil, crushed stone soil, and block stone soil; or cohesive soil foundation, and when the buried depth of the groundwater level is ≥ 1.5m below the foundation surface, Ip (plasticity index )<17.

[0048] Secondly, when the soil sample satisfies the above conditions, the geological verification is carried out, that is, the static force-based method is used to compare the penetration resistance Ps value, the basic bearing capacity of the foundation, the compressive modulus of the foundation, the groundwat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com