An Online Adjustment Method of Rolling Oil Based on Iron Sheet Classification of Hot Roll System

An adjustment method and rolling oil technology, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of weakening the adhesion of rolling oxide scale, unable to achieve good improvement, and unable to adjust surface quality, etc. Achieve the effect of improving the surface quality of the strip, reducing the number of rolling oil coils used, and reducing the use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] For a certain electro-galvanizing plan (with high requirements on the surface of the strip, usually all rolling oil should be used), the 1-10 blocks of this plan are hot roll materials and transition materials, the 11-46 blocks are electro-galvanized products, and the 47- block 80 pieces of general low carbon mild steel.

[0068] An on-line adjustment method for rolling oil based on the classification of hot-rolled iron sheets, comprising the following steps:

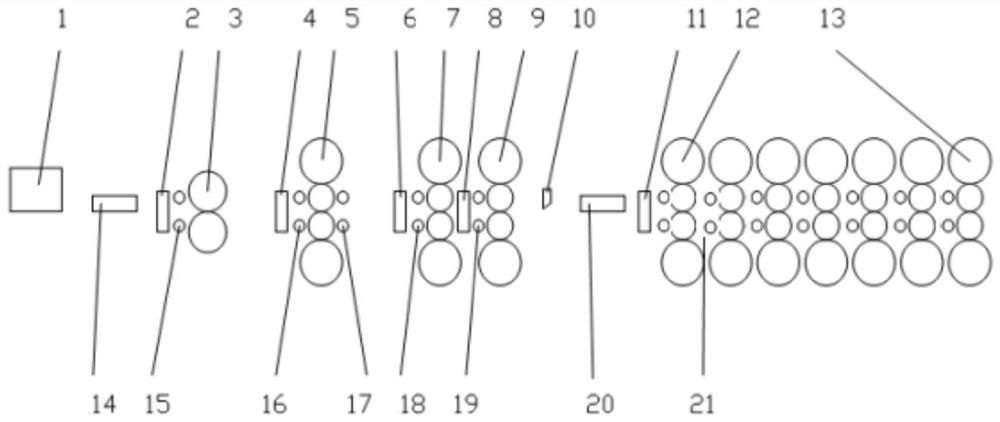

[0069] S1. Setting the initial value of the rolling oil opening; the work rolls are replaced before production of the plan, and the rolling oil opening of F1-F4 is set to 0 after rolling (OilGap=OilGap_ini).

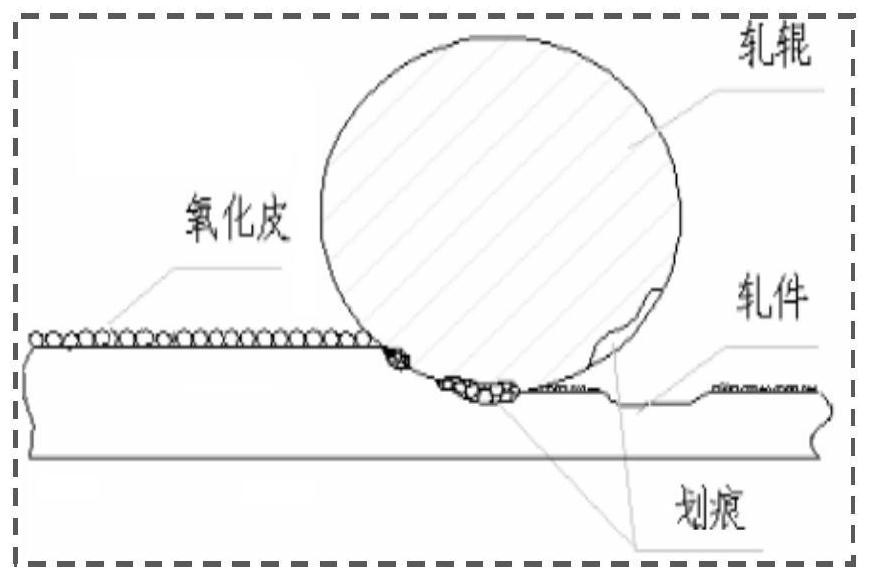

[0070] S2. Collection of iron sheet defects in the strip roll system; during the production process of the plan, the oxide film on the roll surface began to change, and the surface meter collected the surface quality. Obtain table 4 online detection surface defect classification table.

[0071] Table 4: O...

Embodiment 2

[0079] For a pickling plate plan, the first 1-10 rolls of the plan are hot roller materials and transition materials, the 11-56 pieces are in the range of 2.3-6mm, the 47-80 pieces are general low carbon mild steel, and the 80-90 pieces The blocks are pickled thin gauges of 2.1-1.6mm.

[0080] An on-line adjustment method for rolling oil based on the classification of hot-rolled iron sheets, comprising the following steps:

[0081] S1. Setting the initial value of the rolling oil opening; the work rolls are replaced before production of the plan, and the rolling oil opening of F1-F4 is set to 0 after rolling (OilGap=OilGap_ini).

[0082] S2. Collection of iron sheet defects in the strip roll system; during the production process of the plan, the oxide film on the roll surface began to change, and the surface meter collected the surface quality. Obtain table 6 online detection surface defect classification table.

[0083] Table 6: On-line inspection surface defect classificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com