A kind of improved 2m joint and its making method

An improved connector technology, applied in the direction of connection, contact parts, conductive connection, etc., can solve the problems of small space for 2M connectors, unpleasant smell, waste of crimping sleeves, etc., to achieve enhanced connection reliability, good electrical conductivity, The effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

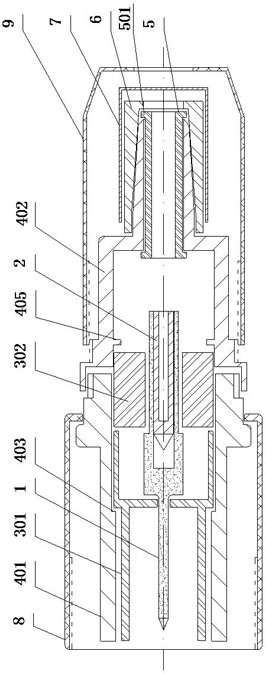

[0053] see figure 1 , an improved 2M connector of the present invention, including signal pin 1, signal pin plug 2, insulators 301, 302, connectors 401, 402, elastic pad 5, fixing nut 6, fixing tube 7, movable connecting body 8 and end cap 9, of which:

[0054] see figure 2 , the front end 101 of the signal pin 1 is a solid structure, and its head is conical, which is used to connect with the corresponding 2M connector on the digital distribution cabinet, and the tail end 102 is a hollow structure for the insertion of the signal pin plug, so The signal pin has a first step portion 103 formed protruding from its outer surface, and the first step portion cooperates with the insulators 301 and 302 to play a limiting role;

[0055] see image 3 , the front end of the signal pin plug 2 is inserted into the signal pin, and the tail end 201 of the signal pin plug is a hollow structure for inserting the core of the 2M data line; the front end 202 of the signal pin plug is headed ...

Embodiment 2

[0083] see Figure 10 , an improved 2M joint described in this embodiment is different from Embodiment 1:

[0084] The tail end of the signal pin plug is provided with a chamfered portion 203 . The chamfered portion makes the tail end of the signal pin plug slightly wider than the front end, which facilitates the insertion of the core of the 2M data cable and is easier to operate.

Embodiment 3

[0086] see Figure 11 , an improved 2M joint described in this embodiment is different from Embodiment 1:

[0087] The tail end of the signal pin plug is provided with a flared section 204, and the flared section 204 is provided with several longitudinal slits. 2 to 4 longitudinal cracks may be provided as required, and the number thereof does not constitute a limitation of the present invention. In this way, the shielding layer of the 2M data cable can be inserted into the flared section to an appropriate depth, so that after crimping, the signal pin plug and the core of the 2M data cable are more firmly fixed, not easy to fall off, and more durable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com