Pressure control equipment for fuel cell

A fuel cell and equipment technology, applied in the direction of fuel cell control, fuel cells, fuel cell additives, etc., can solve problems affecting battery use and output power, inconsistency, and increased air pressure fluctuations, etc., to achieve reasonable and effective use of space , Improve humidification efficiency and control speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

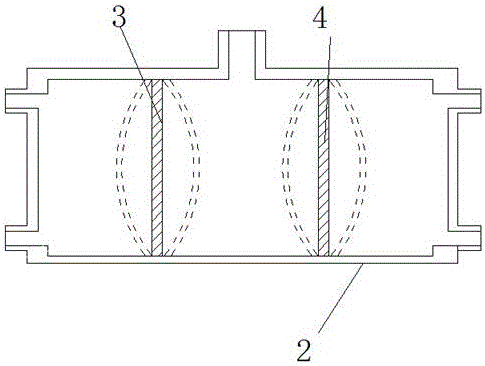

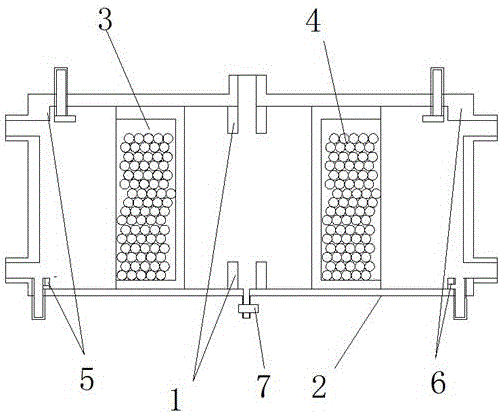

[0030] like figure 2 As shown, the present invention discloses a pressure control device for a fuel cell, comprising a tubular casing 2, which can be provided with a first isolation part 3 and a second isolation part 4, and the casing 2 is divided into a gas cavity, a The air cavity and the pressure regulating cavity, the gas cavity and the pressure regulating cavity are sealed and isolated by the movable first isolation part 3, and the air cavity and the pressure regulating cavity are sealed and isolated by the movable second isolation part 4; the gas cavity is used to communicate with the gas source, and the air The cavity is used to communicate with the air source, and the pressure regulating cavity is used to communicate with the inflation and deflation device. The first isolation part 3 and the second isolation part 4 are piston-shaped; the piston can slide along the side wall of the pipe body, and the two sides of the piston are respectively provided with limit parts so...

Embodiment 3

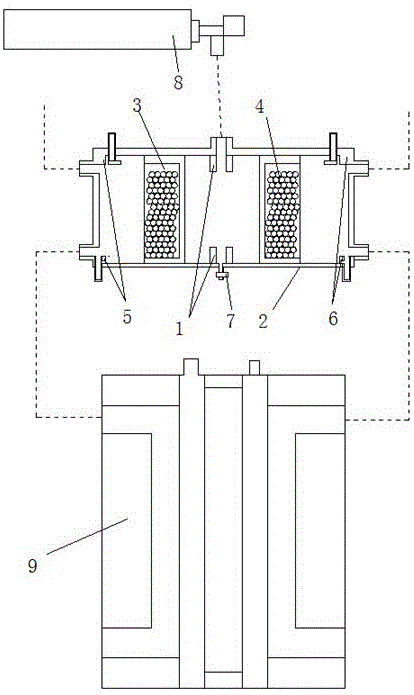

[0034] like image 3 As shown, based on the pressure control device in Example 1, its method for hydrogen fuel cell 9:

[0035] Step 1: The MCU controls the spray pump to output water flow at a speed of 0.8-1.2L / min. The water mist nozzle is in the shape of a flat fan to spray the water mist to the glass beads. The MCU controls the heating lamp to heat the gas cavity and the air cavity. The speed of 10-16m / s is sprayed into the humidity control chamber and humidified to the saturated humidity at the gap between the glass beads. Heating to 80-85℃, then output from the gas outlet / air outlet; the volume ratio of gas flow and water flow in the gas cavity and air cavity is 15-20:1;

[0036] Step 2: The pressure difference between the gas chamber and the pressure regulating chamber controls the movement of the first isolation part 3, and the pressure difference between the pressure regulating chamber and the air chamber controls the movement of the second isolation part 4, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com