Metal magnetic memory triaxial array sensor based on GMR effect

A metal magnetic memory and array sensor technology, which is applied in the direction of instruments, measuring magnetic variables, measuring devices, etc., can solve the problems of difficult to determine the direction, missed detection, wrong detection, etc., achieve low power consumption, avoid false detection and missed detection, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

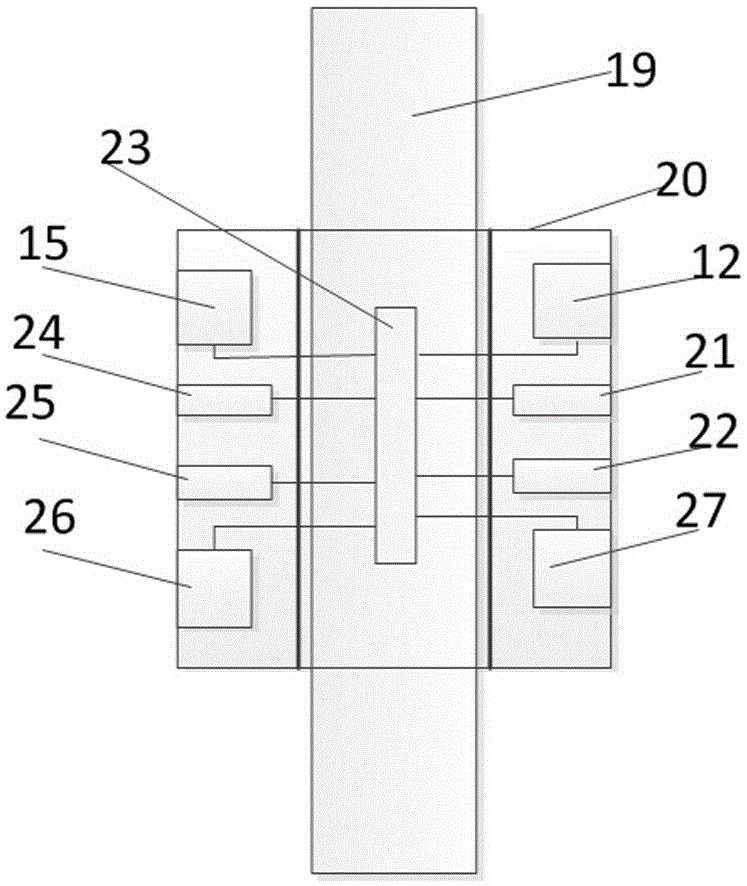

[0013] The sensing probe includes: the giant magnetoresistive magnetic sensor in the X direction of the tangential plane (the first giant magnetoresistive magnetic sensor) 1, the magnetic collecting piece in the X direction of the tangential plane (the first magnetic collecting piece) 2, the giant magnetoresistance in the Y direction of the tangential plane Magnetic sensitive element (the second giant magnetoresistance magnetic sensitive element) 3. The tangential plane Y-direction magneto-collecting sheet (the first magnetic flux-collection sheet) 4. The normal plane Z-direction giant magnetoresistive magnetic-sensitive element (the third giant magnetoresistance magnetic-sensitive element ) 5. Normal plane Z-direction magnetic concentrator (first magnetic concentrator) 6. Probe housing 7. Normal plane signal output data line 8. Tangent plane signal output data line 9. Probe left fixing nut 10. Probe right fixed Nut 11. Wherein, the probe shell 7 is a magnetic shielding shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com