Kaolin calciner with control cable

A technology for controlling cables and kaolin, which is applied in the field of calciners, can solve problems such as poor low-temperature impact resistance, inconvenience in daily work of staff, and shortened service life, so as to enhance the ability of low-temperature impact, shorten calcining time, and facilitate maintenance and the effect of replacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

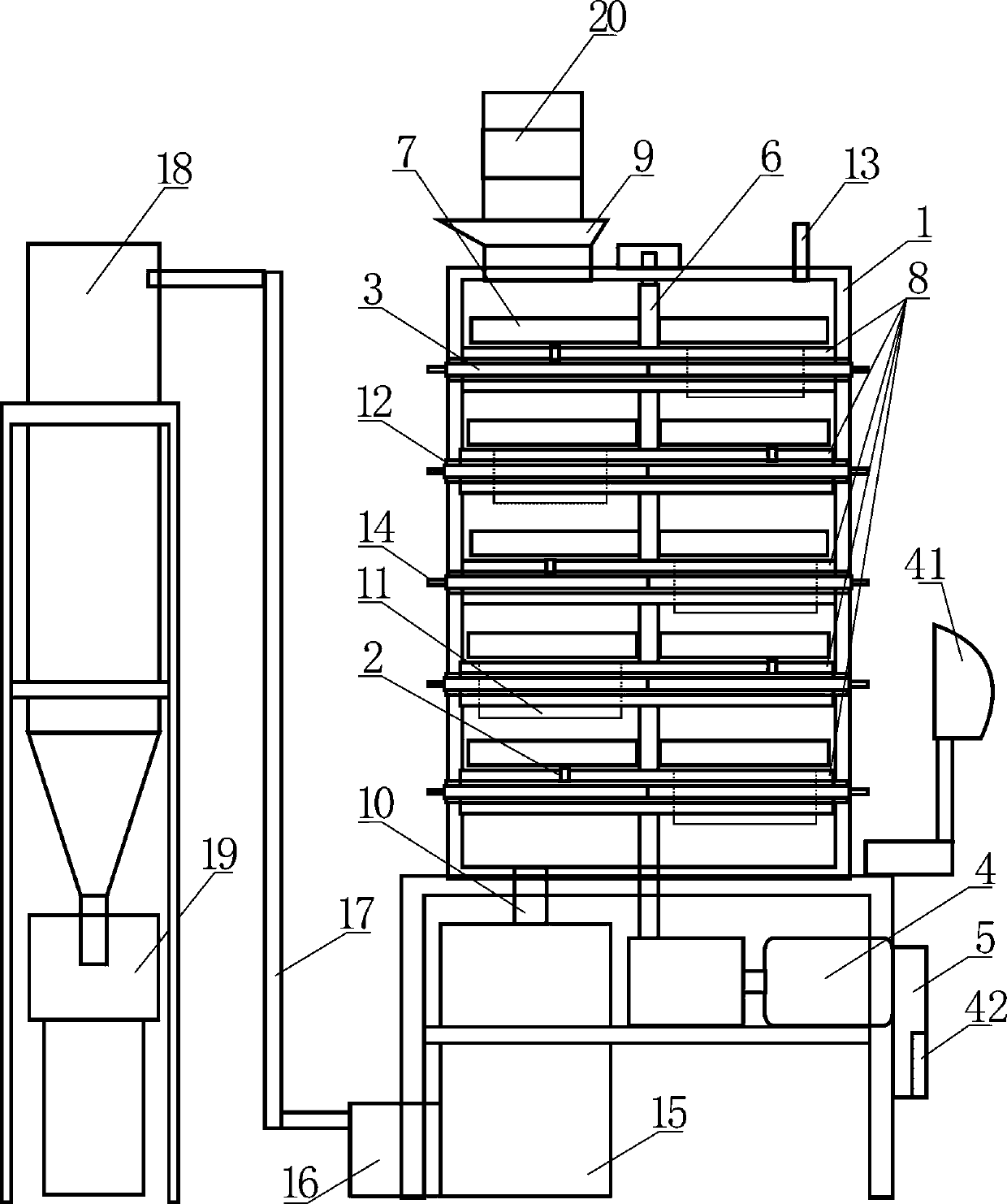

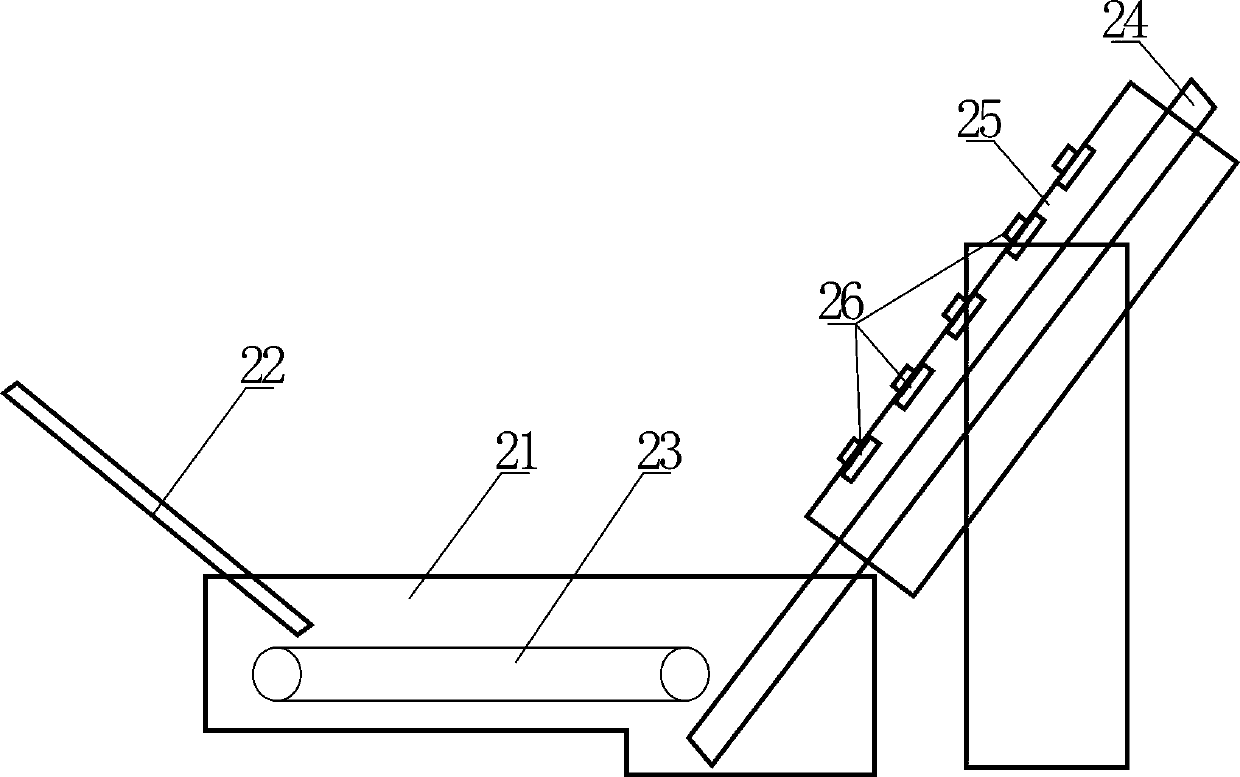

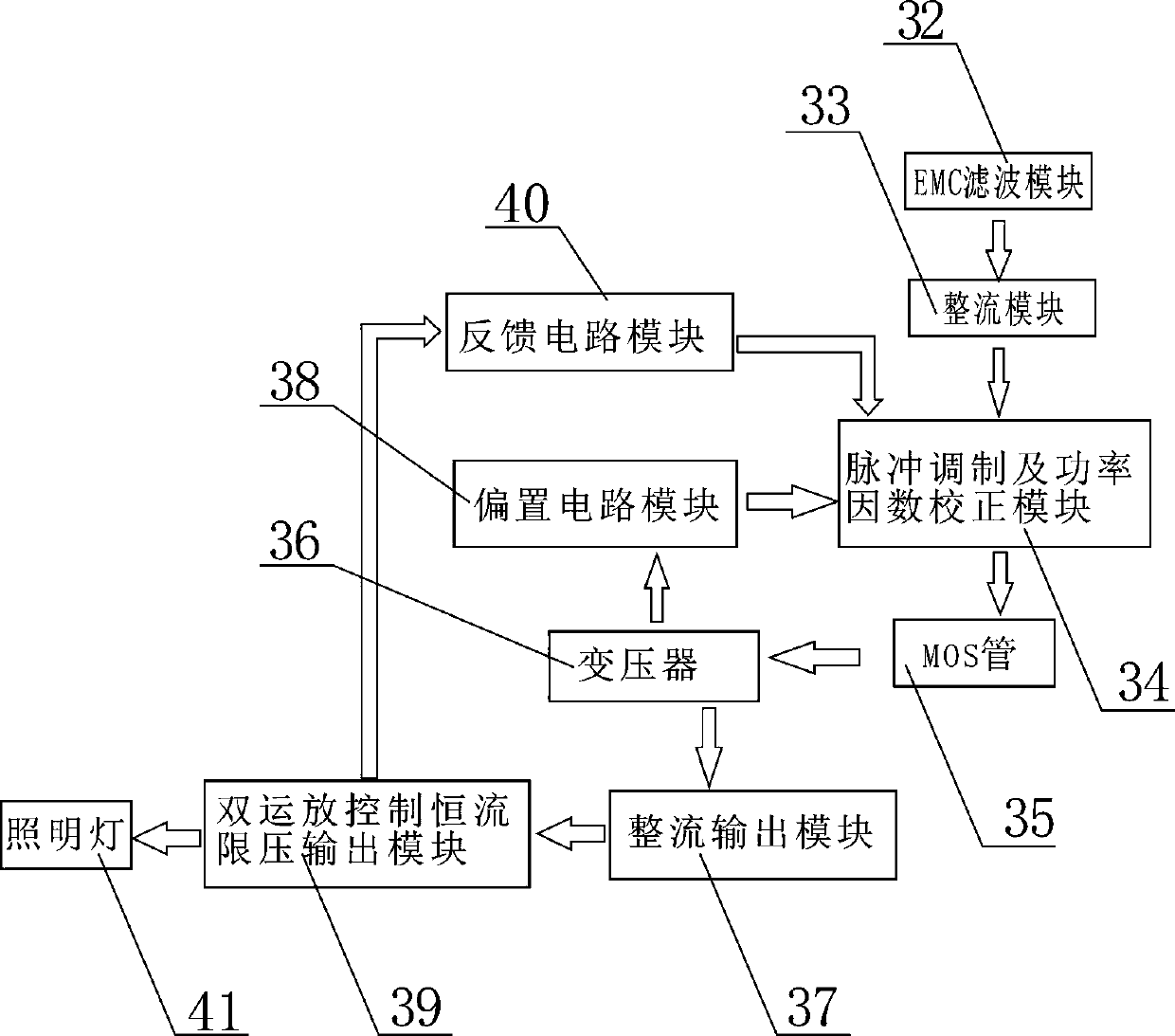

[0028] Such as figure 1 As shown, a kaolin calcining furnace with a control cable includes a furnace body 1, a temperature sensor 2, a heating electric film plate 3, a motor 4, an electric control box 5, a rotating shaft 6 and a pushing scraper 7, the pushing scraper 7 is made of stainless steel. The furnace body 1 has a plurality of hearths 8 distributed from top to bottom at intervals. The hearths 8 are fixed on the inner wall of the furnace body 1, and the top of the furnace body 1 is the feed inlet 9. The bottom is a discharge port 10. The rotating shaft 6 is vertically arranged in the center of the furnace body and passes through each of the hearths 8. The surface of the hearth 8 has a discharge port 11, and the adjacent hearths The blanking ports 11 are staggered, the pushing scraper 7 is parallel to the surface of the hearth 8, one end of the pushing scraper 7 is connected to the rotating shaft 6, the motor 4 is the power source of the rotating shaft 6, and the furnace bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com