Cobalt polluted soil improver and preparation method thereof

A technology for improving and modifying contaminated soil, applied in the field of soil remediation, can solve the problems of secondary soil pollution and unsatisfactory treatment efficiency, and achieve the effect of reducing the cobalt content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

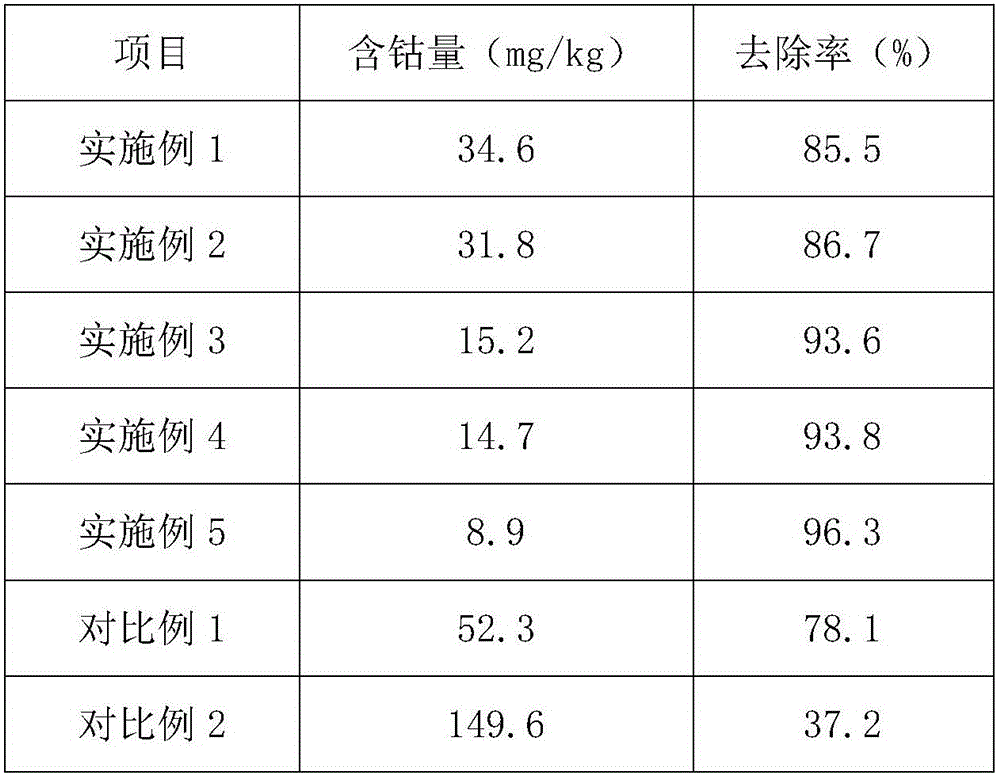

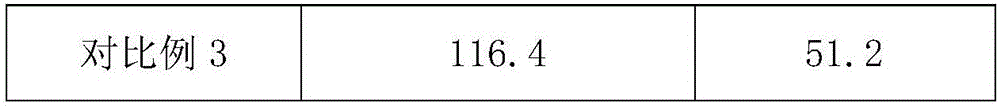

Examples

Embodiment 1

[0015] In the embodiment of the present invention, a cobalt-contaminated soil improver is made of the following raw materials in parts by mass: 24 parts of modified pumice powder, 16 parts of ferrous sulfide, 12 parts of calcium superphosphate, and 11 parts of volcanic glass rock Wherein, the modification step of modified pumice powder is as follows: get pumice stone, be the pumice stone powder of 12 μ m granularity through superfine pulverization; Add pumice stone powder to the mass concentration of 2.4 times of its quality and be in the nitric acid solution of 48%, with 60r / Stir at a speed of 40 min, filter, wash until neutral, and dry; then mix with a sodium tartrate solution with a mass concentration of 16% of 0.42 times the mass of pumice powder, heat to 56°C, and use a power of 300W and a frequency of Ultrasonic treatment at 27 kHz for 20 minutes, filtering, washing, drying, grinding, and passing through a 250-mesh sieve to obtain modified pumice powder.

[0016] The pr...

Embodiment 2

[0018] In the embodiment of the present invention, a cobalt-contaminated soil improver is made of the following raw materials in parts by mass: 28 parts of modified pumice powder, 19 parts of ferrous sulfide, 9 parts of superphosphate, and 7 parts of volcanic glass rock Wherein, the modification step of modified pumice powder is as follows: get pumice stone, be the pumice stone powder of 15 μ m granularity through superfine pulverization; Add pumice stone powder to the mass concentration of 2.6 times of its quality and be in the nitric acid solution of 48%, with 70r / Stir at a speed of 30 min, filter, wash until neutral, and dry; then mix with a sodium tartrate solution with a mass concentration of 16% of 0.45 times the mass of pumice powder, heat to 58°C, and use a power of 320W and a frequency of Ultrasonic treatment at 28 kHz for 15 minutes, filtering, washing, drying, grinding, and passing through a 300-mesh sieve to obtain modified pumice powder.

[0019] The preparation ...

Embodiment 3

[0021] In the embodiment of the present invention, a cobalt-contaminated soil improver is made of the following raw materials in parts by mass: 25 parts of modified pumice powder, 17 parts of ferrous sulfide, 12 parts of calcium superphosphate, and 10 parts of volcanic glass rock Wherein, the modification step of modified pumice powder is as follows: get pumice stone, be the pumice stone powder of 12 μ m particle size through superfine pulverization; Add pumice stone powder to the mass concentration of 2.6 times of its quality and be in the nitric acid solution of 48%, with 60r / Stir at a speed of 40 min, filter, wash until neutral, and dry; then mix with a sodium tartrate solution with a mass concentration of 16% of 0.42 times the mass of pumice powder, heat to 58°C, and use a power of 300W and a frequency of Ultrasonic treatment at 28 kHz for 15 minutes, filtering, washing, drying, grinding, and passing through a 300-mesh sieve to obtain modified pumice powder.

[0022] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com