Boron nitride/epoxy resin composite material and preparation method thereof

A technology of composite materials and epoxy resin, applied in the field of composite materials, can solve the problems of unsatisfactory heat dissipation of devices and low thermal conductivity, and achieve the effect of simple and mild preparation method and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The specific embodiment part of the present invention also provides a kind of preparation method of above-mentioned boron nitride / epoxy resin composite material, and described method comprises the following steps:

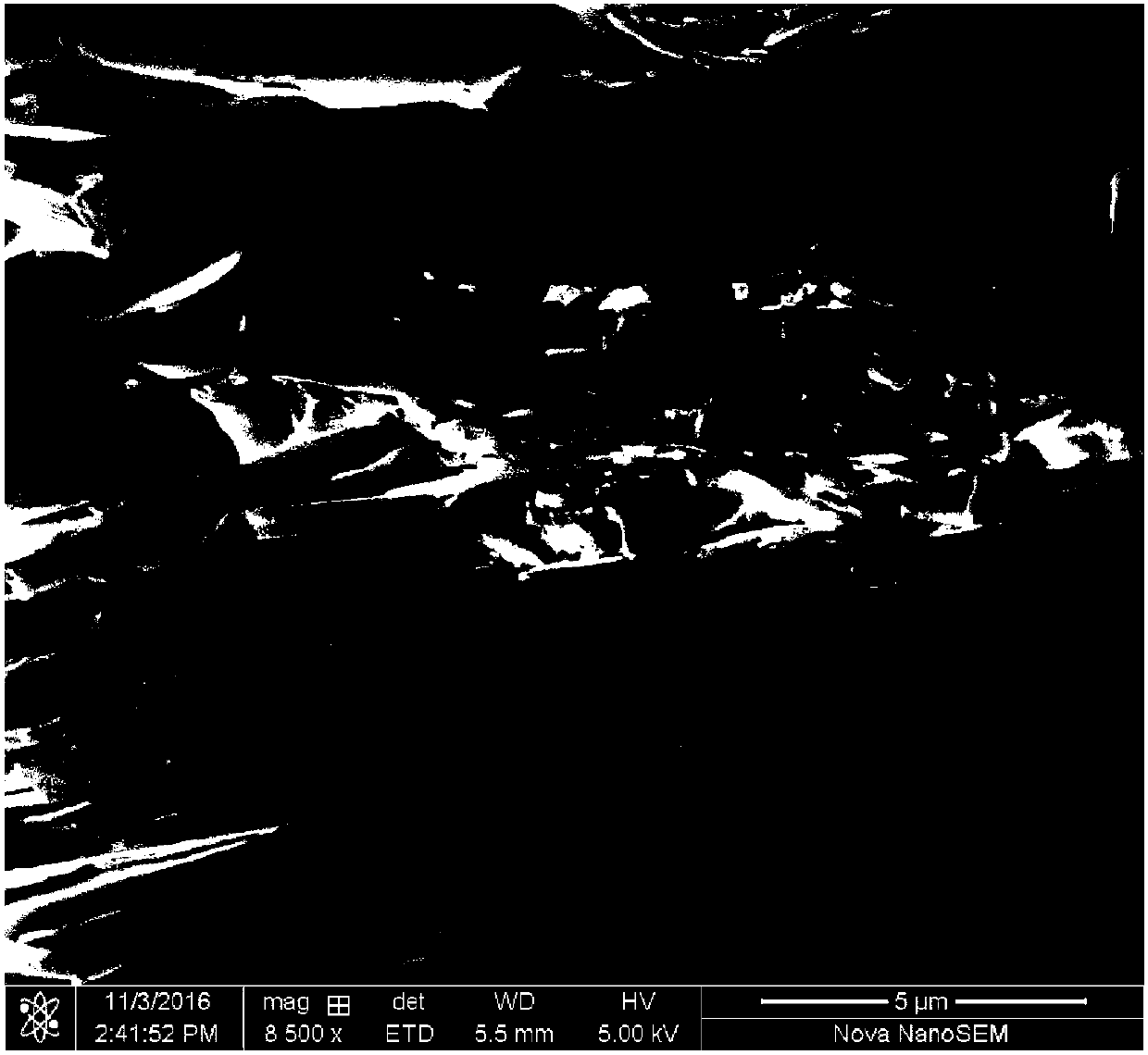

[0046] (1) Boron nitride is added to the aqueous solution of sodium carboxymethyl cellulose, and mixed by ball milling to obtain boron nitride-sodium carboxymethyl cellulose aqueous solution;

[0047] (2) The boron nitride-carboxymethylcellulose sodium aqueous solution obtained in step (1) is rapidly cooled, freeze-dried after complete freezing, and obtains a three-dimensional boron nitride network airgel;

[0048] (3) curing agent and catalyst are added in the epoxy resin, mixed to obtain the epoxy resin mixture;

[0049] (4) injecting the epoxy resin mixture obtained in step (3) into the three-dimensional boron nitride network aerogel obtained in step (2) under reduced pressure, and curing by heating to obtain a boron nitride / epoxy resin composite material...

Embodiment 1

[0052] A preparation method of boron nitride / epoxy resin composite material, said method comprising the following steps:

[0053] (1) Add 2 g of boron nitride to 10 mL of an aqueous solution of sodium carboxymethyl cellulose (the concentration of sodium carboxymethyl cellulose is 10 mg / mL), and mix by ball milling at 200 rpm for 1 h to obtain boron nitride-carboxymethyl Sodium cellulose aqueous solution;

[0054] (2) The boron nitride-carboxymethylcellulose sodium aqueous solution obtained in step (2) is rapidly cooled, and freeze-dried for 48 hours after complete freezing to obtain a three-dimensional boron nitride network airgel;

[0055] (3) Add 0.5g of 4,4'-dihydroxybiphenyl and 0.05g of imidazole to 2g of 4,4'-bis(2,3-epoxypropoxy)biphenolate, mix to obtain epoxy resin mixture ;

[0056] (4) Reduce the pressure to -15Pa, inject the epoxy resin mixture obtained in step (3) into the three-dimensional boron nitride network airgel obtained in step (2) for 2 hours, and then ...

Embodiment 2

[0059] A preparation method of boron nitride / epoxy resin composite material, said method comprising the following steps:

[0060] (1) Add 4g of boron nitride to 10mL of sodium carboxymethyl cellulose in aqueous solution (concentration of sodium carboxymethyl cellulose is 10mg / mL), and mix by ball milling at 200rpm for 12h to obtain boron nitride-carboxymethyl Sodium cellulose aqueous solution;

[0061] (2) The boron nitride-carboxymethylcellulose sodium aqueous solution obtained in step (2) is rapidly cooled, and freeze-dried for 48 hours after complete freezing to obtain a three-dimensional boron nitride network airgel;

[0062] (3) Add 5g of 4,4'-diaminobiphenyl and 0.5g of triphenylphosphine to 8g of 4,4'-biphenol-bis[4-(2-glycidoxy)benzoate] In, mix and obtain epoxy resin mixture;

[0063] (4) Reduce the pressure to -15Pa, inject the epoxy resin mixture obtained in step (3) into the three-dimensional boron nitride network airgel obtained in step (2) for 2 hours, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com