Polyvinyl alcohol full-biodegradation film having water resistance and preparation method thereof

A technology of polyvinyl alcohol and degradable film, which is applied in the field of materials, can solve the problems of easy precipitation and non-environmental protection, and achieve the effects of saving energy, expanding the scope of application and practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

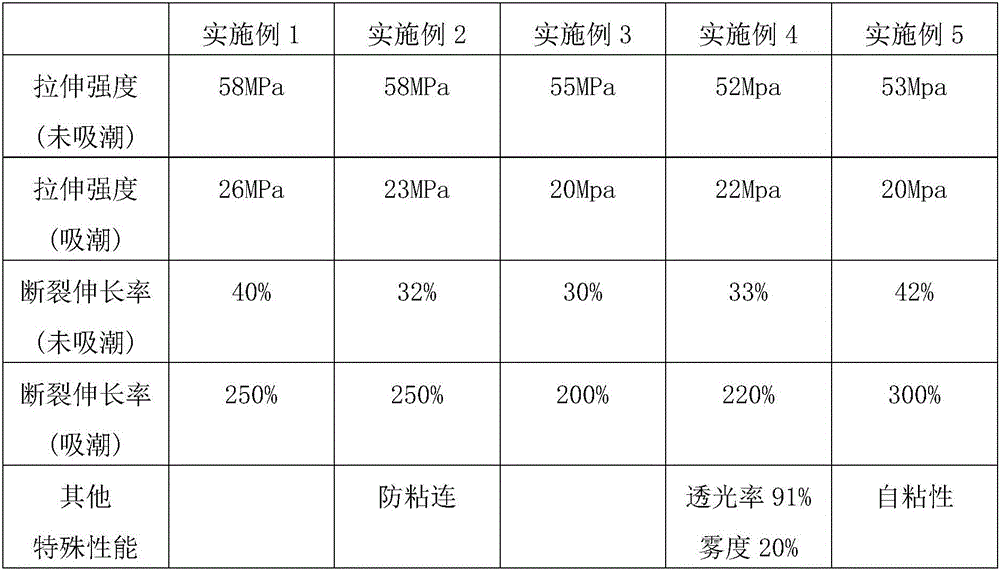

Examples

Embodiment 1

[0035]Calculated in parts by weight, the formula is: polyvinyl alcohol (polymerization degree 400, alcoholysis degree 99%): 100 parts; crosslinking agent borax: 0.5 part; lubricant calcium stearate: 1.5 parts; small molecule plasticizer Water: 15 parts; small molecule plasticizer glycerin: 10 parts; macromolecular plasticizer polylactic acid: 10 parts; acidity remover magnesium hydroxide: 2 parts; heat stabilizer calcium chloride 3 parts.

[0036] Pre-mix the polyvinyl alcohol and borax aqueous solution first, then add other materials and mix well, then add to the double-butterfly extruder to extrude into thin sheets, then directly roll and pull to form a film with a thickness of 5-30 microns , and humidify, cut and roll. The extrusion temperature was 200° C., and the screw speed was 100 rpm.

Embodiment 2

[0038] The formula is: polyvinyl alcohol (polymerization degree 400, alcoholysis degree 99%): 100 parts; crosslinking agent borax: 0.5 part; lubricant calcium stearate: 0.5 part; lubricant silicone composition 2 parts; Plasticizer water: 15 parts; small molecule plasticizer glycerin: 10 parts; macromolecular plasticizer polylactic acid: 10 parts; acidity remover magnesium hydroxide: 2 parts; heat stabilizer calcium chloride 3 parts.

[0039] The processing method and parameter of embodiment 2 are identical with embodiment 1.

[0040] Compared with Example 1, due to the covering effect and anti-blocking effect of the lubricant silicone composition, the surface color of the film in Example 2 is whiter, smoother, and less likely to block. But the disadvantage is the increased cost.

Embodiment 3

[0042] The formula is: polyvinyl alcohol (polymerization degree 400, alcoholysis degree 99%): 100 parts; crosslinking agent borax: 0.5 parts; lubricant calcium stearate: 1.5 parts; small molecule plasticizer water: 15 parts; Molecular plasticizer glycerin: 10 parts; macromolecular plasticizer polylactic acid: 20 parts; acidity remover magnesium hydroxide: 2 parts; heat stabilizer calcium chloride 3 parts.

[0043] The processing method and parameter of embodiment 3 are identical with embodiment 1.

[0044] Compared with Example 1, since the macromolecular plasticizer polylactic acid is increased to 20 parts, the fluidity and melt elasticity of the material are further improved, and the reject rate in film processing is reduced. But the disadvantage is the increased cost.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com