Graphene-modified water-based fluorine alkyd resin and preparation method thereof

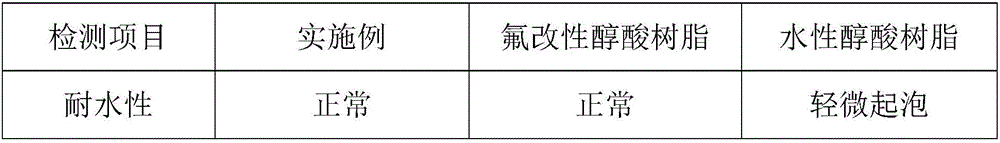

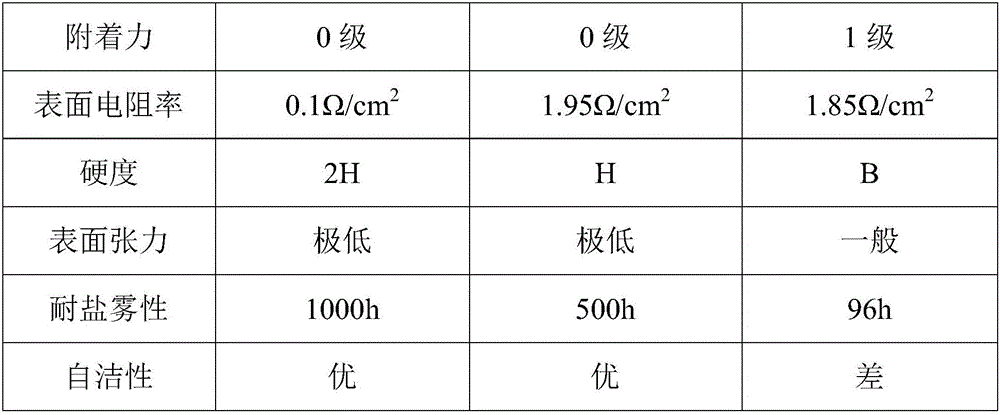

A technology of graphene modification and alkyd resin, applied in the field of water-based synthetic resin, can solve the problems of aging resistance, poor self-cleaning function, poor antistatic performance, uneven dispersion of additives, etc., and achieve excellent performance and antistatic Excellent effect, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A graphene modified water-based fluoroalkyd resin, its preparation process is as follows:

[0032] a. Add 2.0 parts of graphene oxide and 2.0 parts of dimethylolpropionic acid into a four-port reactor equipped with a thermometer, condenser and stirrer, and add 8.0 parts of polyisocyanate dropwise at a constant speed of 60-70 ° C under stirring conditions, The dropping time is 1h, then continue to heat up to 80°C, and keep warm for 2h to obtain the active intermediate A, which is ready for use;

[0033] b. In a reactor with a stirring and dripping device, add 4.0 parts of acrylic monomer, 3.0 parts of fluoroolefin monomer and 0.07 part of catalyst azobisisobutyronitrile according to the recipe requirements, and stir evenly to obtain a monomer Mixture B, ready to use;

[0034]c. In a four-port reactor equipped with a thermometer, condenser, water separator, and agitator, add 8.0 parts of vegetable oil fatty acid, 2.5 parts of phthalic anhydride, 4.0 parts of neopentyl gl...

Embodiment 2

[0037] A graphene modified water-based fluoroalkyd resin, its preparation process is as follows:

[0038] a. Add 2.5 parts of graphene oxide and 2.0 parts of dimethylolpropionic acid into a four-port reactor equipped with a thermometer, condenser and stirrer, and add 8.5 parts of polyisocyanate dropwise at a constant speed of 60-70 ° C under stirring conditions, The dropping time is 1h, then continue to heat up to 80°C, and keep warm for 2h to obtain the active intermediate D, which is ready for use;

[0039] b. In the reactor with stirring and dripping device, add 4.5 parts of acrylic monomer, 3.5 parts of fluoroolefin monomer and 0.08 part of catalyst azobisisobutyronitrile according to the recipe requirements, and stir evenly to obtain a monomer Mixture E, ready to use;

[0040] c. In a four-port reactor equipped with a thermometer, condenser, water separator, and agitator, add 8.5 parts of vegetable oil fatty acid, 2.0 parts of phthalic anhydride, 4.5 parts of neopentyl g...

Embodiment 3

[0043] A graphene modified water-based fluoroalkyd resin, its preparation process is as follows:

[0044] a. Add 3.5 parts of graphene oxide and 1.5 parts of dimethylolpropionic acid into a four-port reactor equipped with a thermometer, condenser and stirrer, and add 9.5 parts of polyisocyanate dropwise at a constant speed of 60-70 ° C under stirring conditions, The dropping time is 1h, then continue to heat up to 80°C, and keep warm for 2h to obtain the active intermediate G, which is ready for use;

[0045] b. In a reactor with a stirring and dripping device, add 3.5 parts of acrylic monomer, 2.5 parts of fluoroolefin monomer and 0.06 part of catalyst azobisisobutyronitrile according to the recipe requirements, and stir evenly to obtain a monomer Mixture H, ready to use;

[0046] c. In a four-port reactor equipped with a thermometer, condenser, water separator, and agitator, add 9.5 parts of vegetable oil fatty acid, 2.5 parts of phthalic anhydride, 5.5 parts of neopentyl g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com