Method for producing isopropyl acetate through heat pump partition-wall reactive distillation tower

A technology of reactive distillation column and isopropyl acetate, applied in the field of rectification, can solve problems such as high energy consumption, and achieve the effects of reducing energy consumption, reducing energy and saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

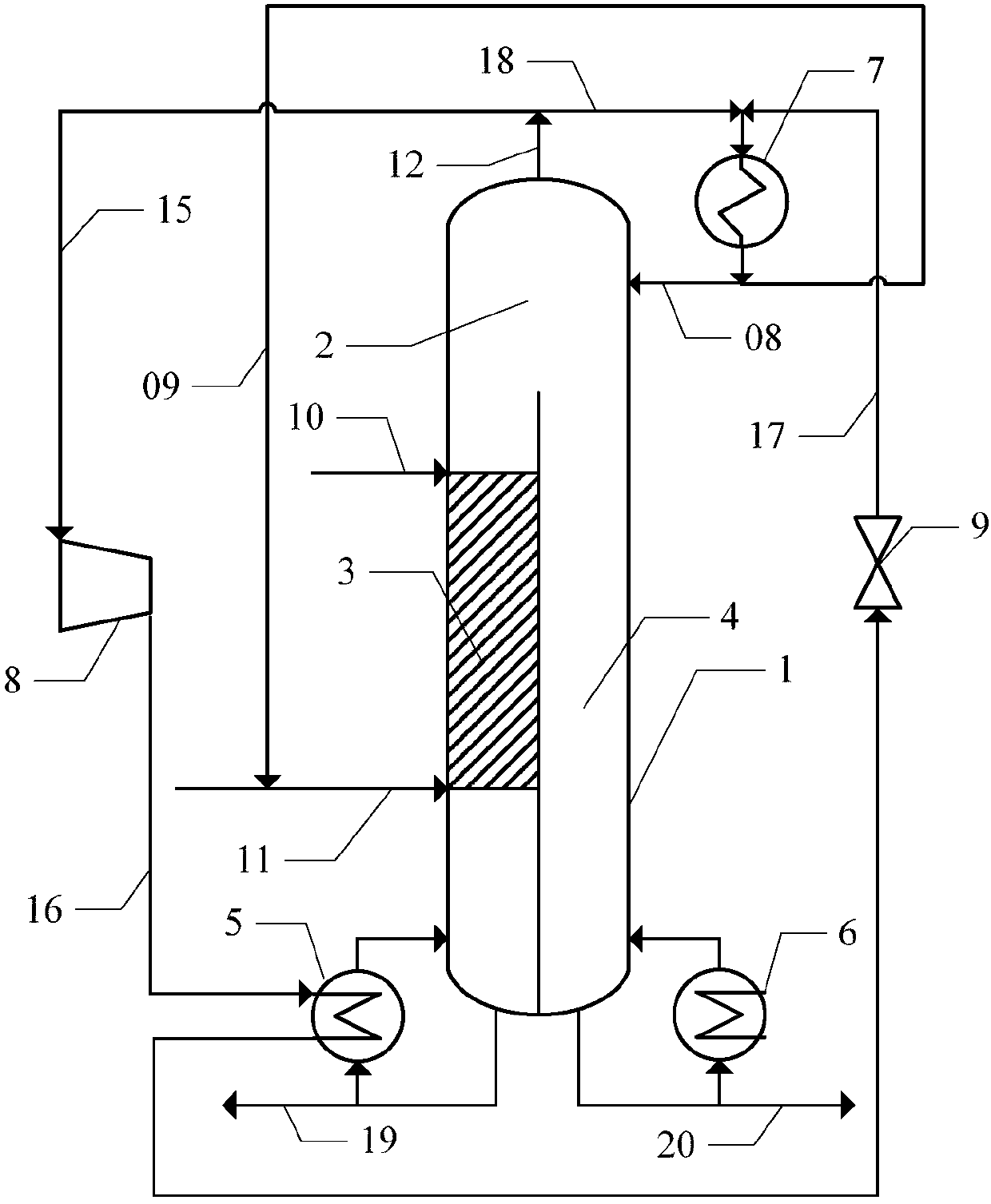

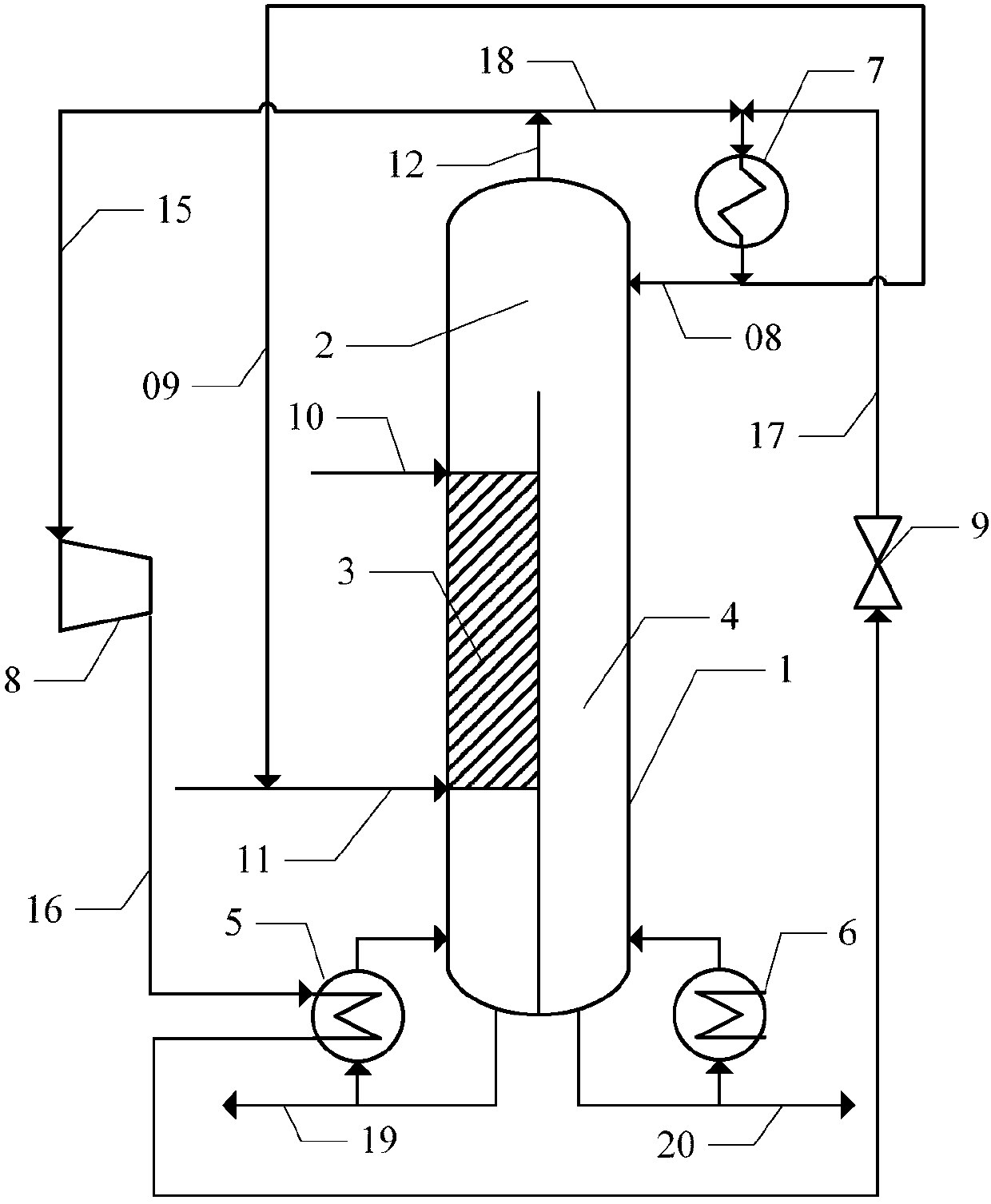

[0024] Attached figure 1In the process flow shown, the heat pump dividing wall reactive distillation column 1 used is a packed tower with a diameter of 2300 mm and 45 meters. The top separation area 2 is equipped with 5 meters of structured packing, and the number of theoretical plates is 10; the reaction separation area 3 is equipped with The structured packing is 35 meters, and the number of theoretical plates is 74, including 9 plates in the rectification section and 43 plates in the reaction section. The reaction section is filled with solid catalyst, the catalyst used is Amberlyst-15 strong acid cation exchange resin, and 12 plates in the stripping section plate. Methanol recovery zone III is filled with 5 meters of structured packing, the operating pressure of the heat pump dividing wall reactive distillation column RDWC is 1 atm, the top temperature of the top separation zone 2 is 54°C, the bottom temperature of the reaction separation zone 3 is 91°C, and the methanol r...

Embodiment 2

[0027] with attached figure 1 In the process flow shown, the heat pump dividing wall reactive distillation column 1 used is a tray column with a diameter of 2100 mm and a height of 50 meters. There are 10 trays in the top separation area 2; the number of trays in the reaction separation area 3 is 76 Blocks, including 10 plates in the rectification section, 44 plates in the reaction section, filled with a solid catalyst in the reaction section, the catalyst used is Amberlyst-15 strongly acidic cation exchange resin, and 12 plates in the stripping section. There are 6 trays in the methanol recovery area 4, the operating pressure of the heat pump dividing wall reaction distillation column 1 is 2 atm, the top temperature of the tower top separation area 2 is 73 °C, the bottom temperature of the reaction separation area 3 is 113 °C, and the bottom of the methanol recovery area 4 The temperature is 83°C.

[0028] The raw material isopropanol is fed from the upper part of the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com