Low energy consumption drying treatment technology of residual activated sludge

A technology of residual activity and treatment process, which is applied in the direction of sludge treatment through temperature control, dehydration/drying/concentration sludge treatment, energy wastewater treatment, etc. Problems such as low moisture content can be achieved by shortening the breaking time, reducing the dosage of chemicals, and improving the cracking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

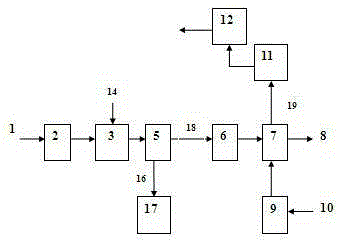

Method used

Image

Examples

Embodiment 1

[0028]The specific embodiment of the present invention is illustrated by taking the excess sludge of a certain refinery sewage treatment plant as an example. The content analysis of the remaining sludge raw materials is shown in Table 1. Add 0.05% TS octylphenol polyoxyethylene ether and 0.02% alkyl glycoside to 200kg of the excess sludge with a water content of 96.7%, and add 1% TS hydroxyethyl hexahydro-s-triazine, start The high-speed shearing knife performs high-speed shearing and breaking of the sludge wall at a speed of 20,000r / min for 30 minutes; after the wall is broken, the sludge is subjected to centrifugal dehydration. Enter the biochemical unit of the sewage treatment plant for further treatment. After dehydration, the mud cake enters the filter press to be pressed into a 4mm strip sludge and enters the solar multi-layer mesh belt low-temperature drying box through the conveyor belt. The carrier gas is heated to 50°C by the solar tube. The humidity in the box is 8...

Embodiment 2

[0035] It is basically the same as Example 1, except that the treating agent is 0.08% TS nonylphenol polyoxyethylene ether and 0.04% alkyl glucoside, and adding 1.5% TS of hydroxyethyl hexahydro-s-triazine, dried The moisture content of the remaining sludge dropped to 11.4%. The remaining sludge volume was reduced by nearly 88%.

Embodiment 3

[0037] It is basically the same as that of Example 1, except that the inlet temperature of the solar multi-layer mesh belt type low-temperature drying box, the amount of carrier gas and the residence time in the box are adjusted. After dehydration, the mud cake enters the filter press to be pressed into 4mm strips. The sludge enters the solar multi-layer mesh belt low-temperature drying box through the conveyor belt. The carrier gas is heated to 60°C by the solar tube, the humidity in the box is 5%, and the carrier gas volume is 200m 3 / h, the residence time of the sludge in the tank is 1.5h, and the moisture content of the sludge drops to 9.3% after drying. The remaining sludge volume was reduced by nearly 87%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com