Method for preparing nitrogen-atom doped carbon nanomaterial

A technology of carbon nanomaterials and nanomaterials, which is applied in the field of hybrid carbon materials and its preparation, can solve the problems of product specific surface area decrease, low nitrogen atom doping amount, and no improvement, etc., and achieve simple and easy process, high specific surface area Great, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

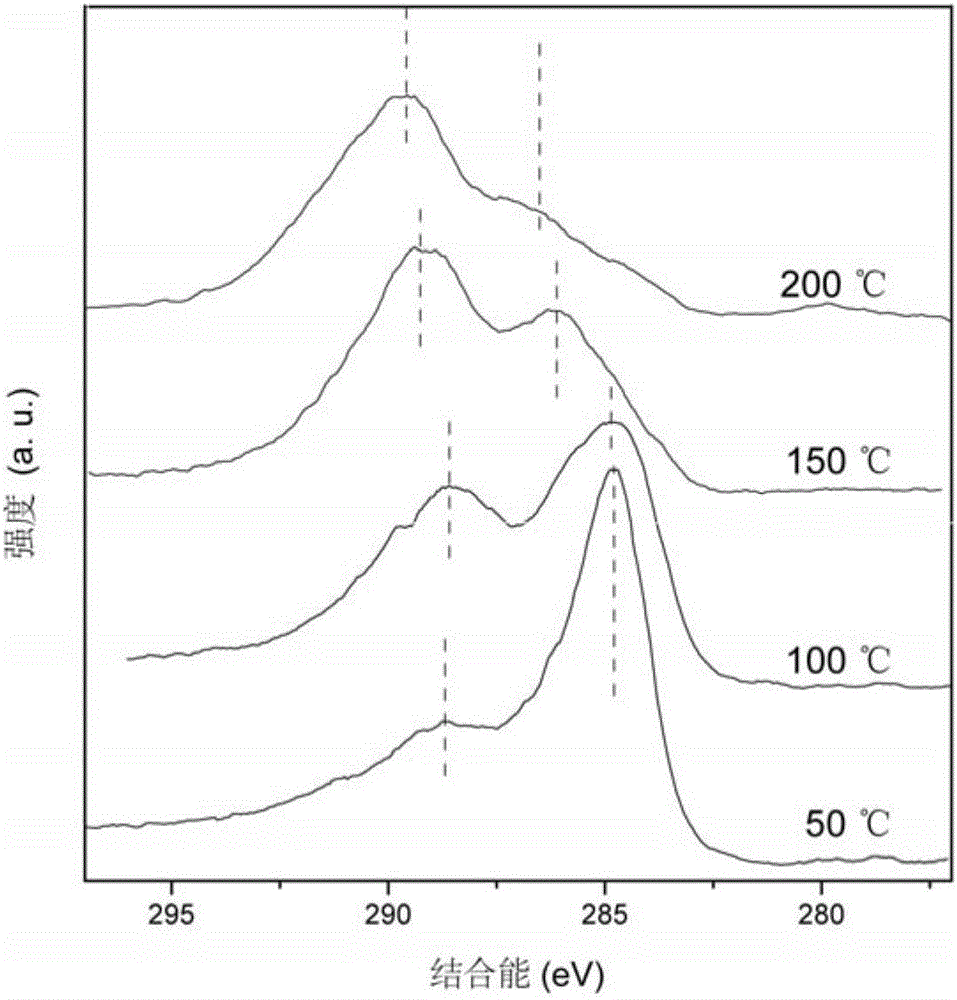

Method used

Image

Examples

Embodiment 1

[0028] Graphene is placed in a closed vacuum reactor, and the air in the reactor is replaced with argon for three times, then vacuumized, then filled with a mixture of fluorine and argon, and the initial partial pressure of fluorine in the reactor is controlled to be 30KPa, then raise the temperature to 80°C at a heating rate of 10°C / min and keep it warm for 300 minutes. After the reactor is naturally cooled to room temperature, the fluorinated graphene is taken out. Put the fluorinated graphene into the tube furnace and feed the mixed gas of ammonia / argon, the concentration of ammonia is 30%, the flow rate is 1Torr, and the temperature is raised to 700°C at a heating rate of 10°C / min, and kept warm 0.5 hours. After the tube furnace was cooled to room temperature, the obtained nitrogen-doped graphene was taken out.

[0029] The nitrogen content of this nitrogen-doped graphene is 5.4%, and the specific surface area is 443m 2 / g.

Embodiment 2

[0031] Place the multi-walled carbon nanotubes in a closed vacuum reactor, replace the air in the reactor with nitrogen three times, then evacuate it, then fill it with a mixture of fluorine and nitrogen, and control the initial partial pressure of fluorine in the reactor to 80KPa, then raise the temperature to 250°C at a heating rate of 20°C / min and keep it warm for 10 minutes. After the reactor is naturally cooled to room temperature, the fluorinated multi-walled carbon nanotubes are taken out. Put the fluorinated multi-walled carbon nanotubes into the tube furnace and pass through the ammonia / nitrogen mixed gas, wherein the concentration of ammonia is 2%, the flow rate is 20Torr, and the temperature is raised to 400°C at a heating rate of 20°C / min. And keep warm for 24 hours. After the tube furnace was cooled to room temperature, the obtained nitrogen-doped multi-walled carbon nanotubes were taken out.

[0032] The nitrogen content of the nitrogen-doped multi-walled carbon...

Embodiment 3

[0034] Graphene oxide is placed in a closed vacuum reactor, the air in the reactor is replaced with nitrogen for three times and then vacuumized, then filled with a mixture of fluorine and argon, and the initial partial pressure of fluorine in the reactor is controlled to 3KPa, then raise the temperature to 150°C at a heating rate of 1°C / min and keep it warm for 60 minutes. After the reactor is naturally cooled to room temperature, the fluorinated graphene oxide is taken out. Put the fluorinated graphene oxide into the tube furnace and feed the ammonia / argon mixed gas, wherein the concentration of ammonia is 15%, the flow rate is 10Torr, and at the same time, the temperature is raised to 550°C at a heating rate of 3°C / min, and Keep warm for 6 hours. After the tube furnace was cooled to room temperature, the nitrogen-doped graphene was obtained.

[0035] The nitrogen content of this nitrogen-doped graphene is 6.4%, and the specific surface area is 643m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com