Mold oil cylinder core-pulling sliding block retaining circuit used in injection process of injection molding machine

A technology of injection process and cylinder core-pulling, which is applied in the field of mold cylinder core-pulling slider stop-return circuit, can solve the problems of product quality decline, unqualified, scrapped, etc., and achieve the effect of preventing the mold from not being in place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

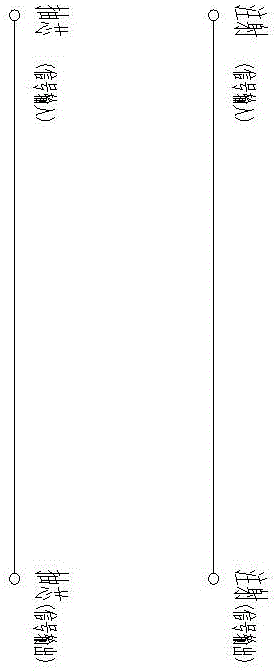

[0016] Such as figure 1 Shown is the control circuit diagram of the prior art, including the core-pulling input terminal, the core-pulling output terminal, the injection input terminal, and the injection output terminal; the core-pulling input terminal is connected to the core-pulling output terminal, and the core-pulling input terminal sends out a signal to control the core-pulling valve Action; the injection input end is connected with the injection output end, the injection input end sends out a signal, and the injection action starts when the computer injection end of the plastic machine provides the injection signal.

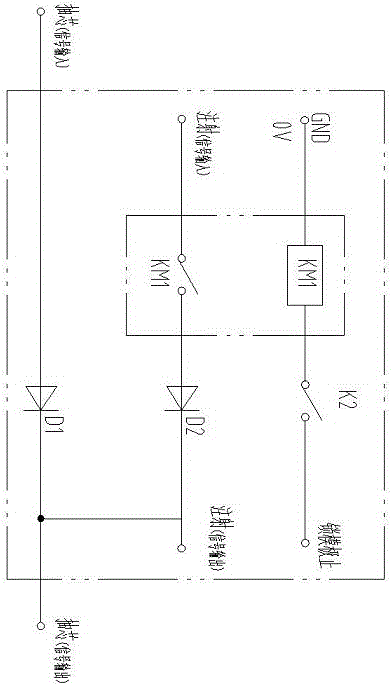

[0017] Such as figure 2 Shown is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com