Die forging process and equipment for outer star wheel and inner star wheel blanks for automobile transmission shaft

A technology of outer star wheel and inner star wheel, which is applied in metal processing equipment, wheels, vehicle parts, etc., can solve the problems of low material utilization rate, low production efficiency, and low material utilization rate, so as to reduce energy consumption, The effect of improving labor efficiency and reducing the quality of forgings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

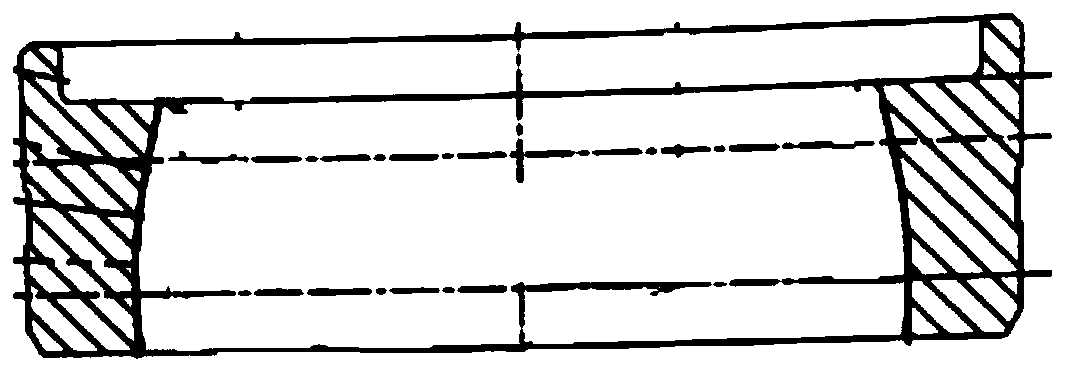

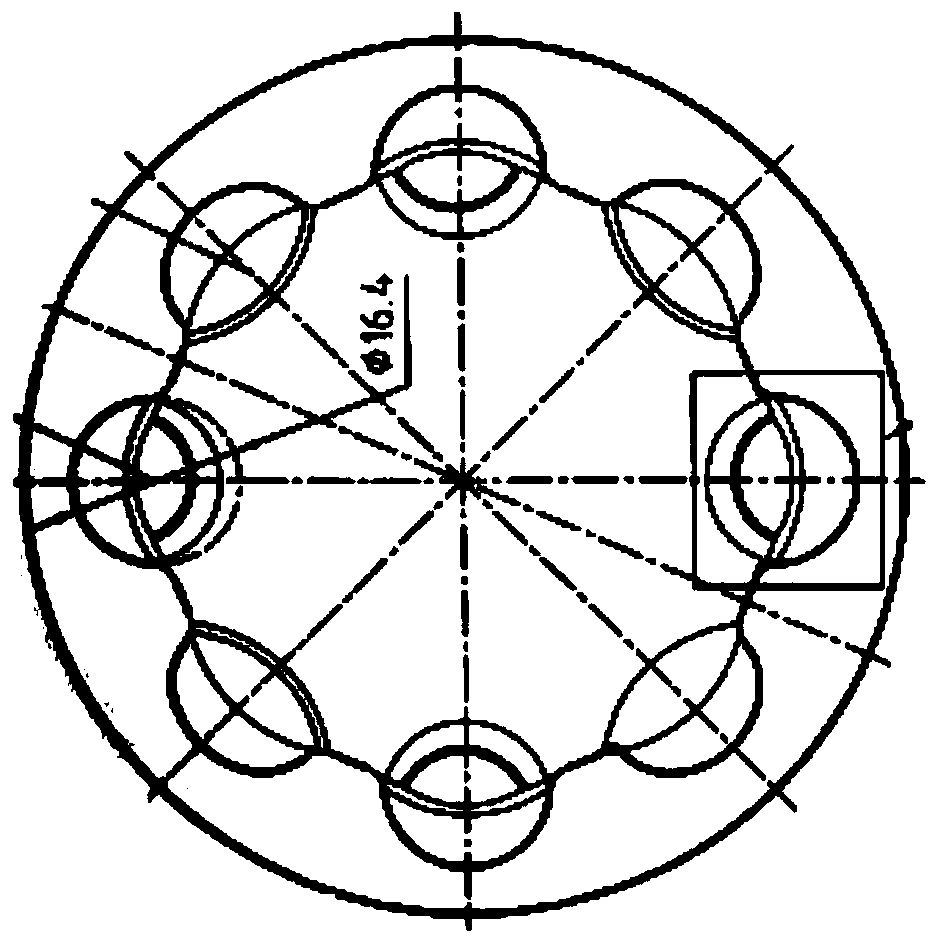

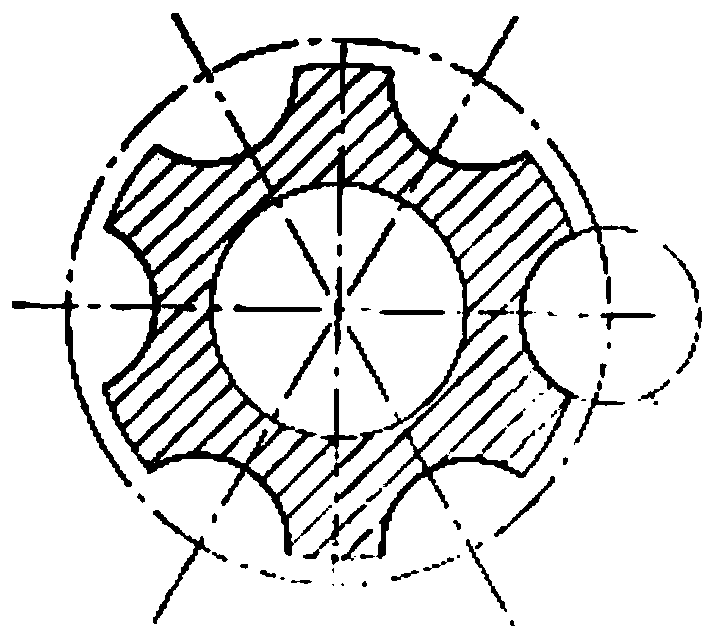

[0035] see Figure 4-9 , a kind of die forging process of outer star wheel and inner star wheel blank for automobile transmission shaft, comprising the following steps: S1, pre-forging: the shape between the upper mold core and the lower mold core of the pre-forging mold is the outer star wheel blank A structure that is integrated with the inner star wheel blank, wherein the bottom of the outer star wheel blank is integrated with the upper part of the inner star wheel blank; S2, final forging: further forging and forming the pre-forged blank; S3, Stamping division: The inner star wheel blank and the outer star wheel blank of the final forged blank are divided by stamping.

[0036] see Figure 5-6 , during final forging: the height of the connecting part of the inner and outer star wheel blanks is A, the distance from the connecting part of the inner and outer star wheel to the upper end of the inner star wheel is B, the width of the connecting part of the inner and outer star...

Embodiment 2

[0039] A kind of above-mentioned equipment for die forging process of outer star wheel and inner star wheel blank for automobile transmission shaft, including pre-forging equipment, final forging equipment, stamping and cutting equipment; The shape of the space between them is a pre-forging structure in which the outer star wheel blank and the inner star wheel blank are connected as a whole, wherein the bottom of the outer star wheel blank is connected with the upper part of the inner star wheel blank; the upper part of the final forging equipment The shape of the space between the mold core and the lower mold core is a final forging structure in which the outer star wheel blank and the inner star wheel blank are connected together; Hole trimming punch 13, stripping plate 8; the stripping plate 8 is connected with the upper die base 10 through an elastic mechanism, and corresponds to the upper part of the outer star wheel blank part of the blank to be forged; the sleeve forging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com