Supersonic nozzle

A supersonic, nozzle technology, applied in the field of fluid mechanics and solid-phase chemical reaction, can solve the problems of low kinetic energy of material particles, difficult feeding, low collision reaction efficiency, etc., and achieve the effect of uniform flow field, high kinetic energy and excellent technical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

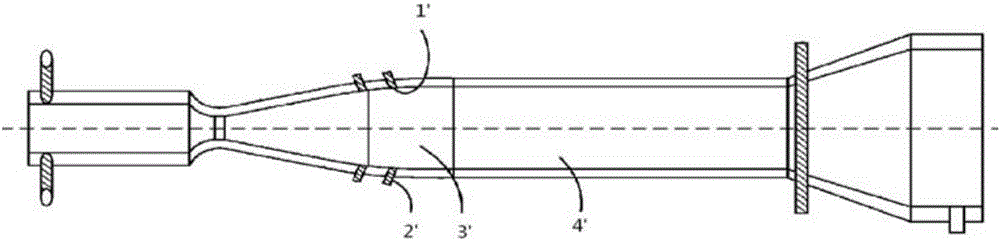

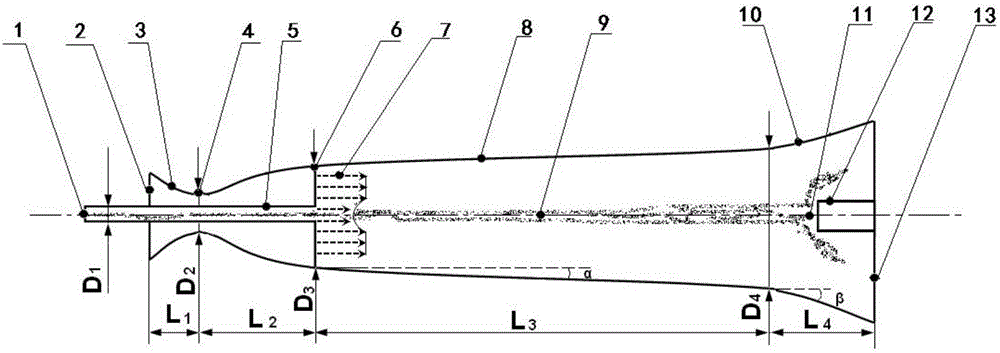

[0025]The supersonic nozzle, along the flow direction of the airflow, the annular shrinking and expanding nozzle 3 is sequentially connected with the first section 8 of the accelerating tube and the second section 10 of the accelerating tube, and forms a through inner cavity. An ejected feeding pipe 5 is provided throughout, the inlet end of the ejected feeding pipe 5 is connected to solid particles or powder and the normal ballast air flow, the outlet end extends to the first section 8 of the accelerating tube, and the inner space of the shrinking and expanding nozzle 3 is Divided into the inner flow channel of the injection feeding tube 2 and the annular contraction and expansion flow channel; a cylindrical target head 12 is arranged at the end of the second section 10 of the acceleration tube. The annular shrinking and expanding nozzle 3 is integrally formed, including a shrinking section and an expanding section. The transitional joint of the two sections is a throat 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com