Glucose-containing lipid emulsion sterilizing method

A technology of fat emulsion and glucose, which is applied in the direction of medical preparations containing active ingredients, pharmaceutical formulas, emulsion delivery, etc., can solve problems such as the inability to guarantee the quality of glucose-containing fat emulsion products, and achieve better sterilization effects and no dead ends , heat transfer fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The preparation method of the sterilized preparation of the glucose-containing fat emulsion of the present invention is as follows: the glucose-containing fat emulsion prepared by a high-pressure homogenizer, with an average particle size of 290 nm, is filled into a soft package with a medicinal solution. Put the soft package into the rotary sterilizer, feed high-temperature steam, rapidly raise the temperature inside the sterilizer to 115 ℃ within 3 minutes, maintain the pressure at 0.15 MPa, maintain the time within 45 minutes, and rotate at 5 revolutions per minute . After the sterilization is completed, automatic water spraying is carried out. After about 60 minutes, the temperature drops to 50°C, the pressure is zero, and the door of the disinfection cabinet is opened.

Embodiment 2

[0019] The preparation method of the sterilized preparation of the glucose-containing fat emulsion of the present invention is as follows: the glucose-containing fat emulsion prepared by a high-pressure homogenizer, with an average particle diameter of 305nm, is filled into a soft package with a medicinal solution. Put the soft package into the rotary sterilizer, feed high-temperature steam, and rapidly raise the temperature inside the sterilizer to 121°C within 3 minutes, maintain the pressure at 0.2MPa, maintain the time within 30 minutes, and rotate at 3 revolutions per minute . After the sterilization is completed, automatic water spraying is carried out. After about 60 minutes, the temperature drops to 50°C, the pressure is zero, and the door of the disinfection cabinet is opened.

Embodiment 3

[0021] The preparation method of the sterilized preparation of the glucose-containing fat emulsion of the present invention is as follows: the glucose-containing fat emulsion prepared by a high-pressure homogenizer, with an average particle diameter of 298 nm, is filled into a flexible package with a medicinal solution. Put the soft package into the rotary sterilizer, feed high-temperature steam, and quickly raise the temperature inside the sterilizer to 121°C within 3 minutes, maintain the pressure at 0.2 MPa, and maintain the time within 30 minutes, at a speed of 5 revolutions per minute . After the sterilization is completed, automatic water spraying is carried out. After about 60 minutes, the temperature drops to 50°C, the pressure is zero, and the door of the disinfection cabinet is opened.

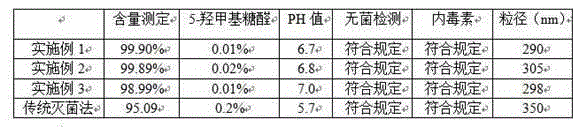

[0022] Embodiment 1-3 principal ingredient content and other each index are as follows:

[0023]

[0024] The above data shows that the glucose-containing fat emulsion prepared b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com