Co(vo3)2-mn(vo3)2 with different shapes and its preparation method and application

A morphology and solution technology, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problem of not preparing a pencil-like structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

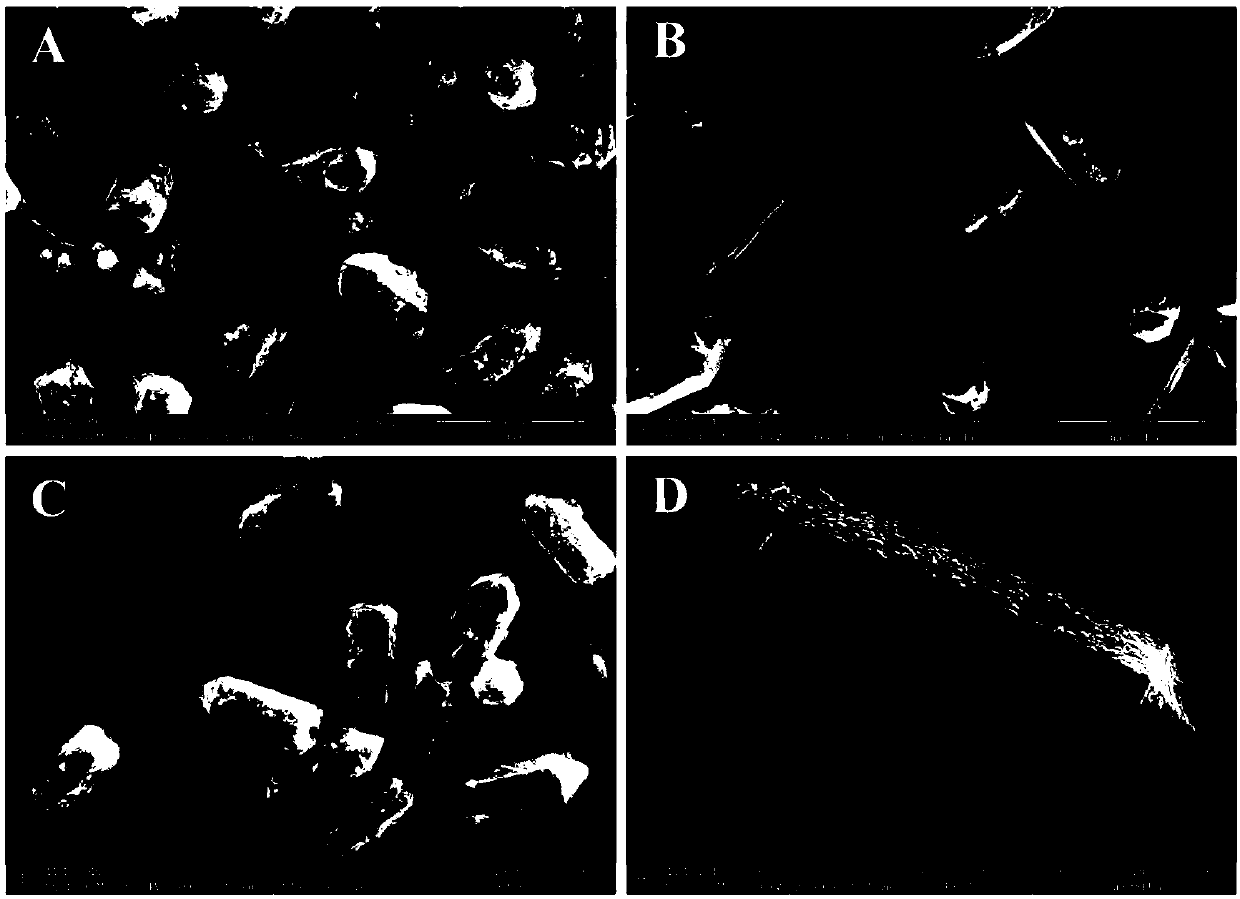

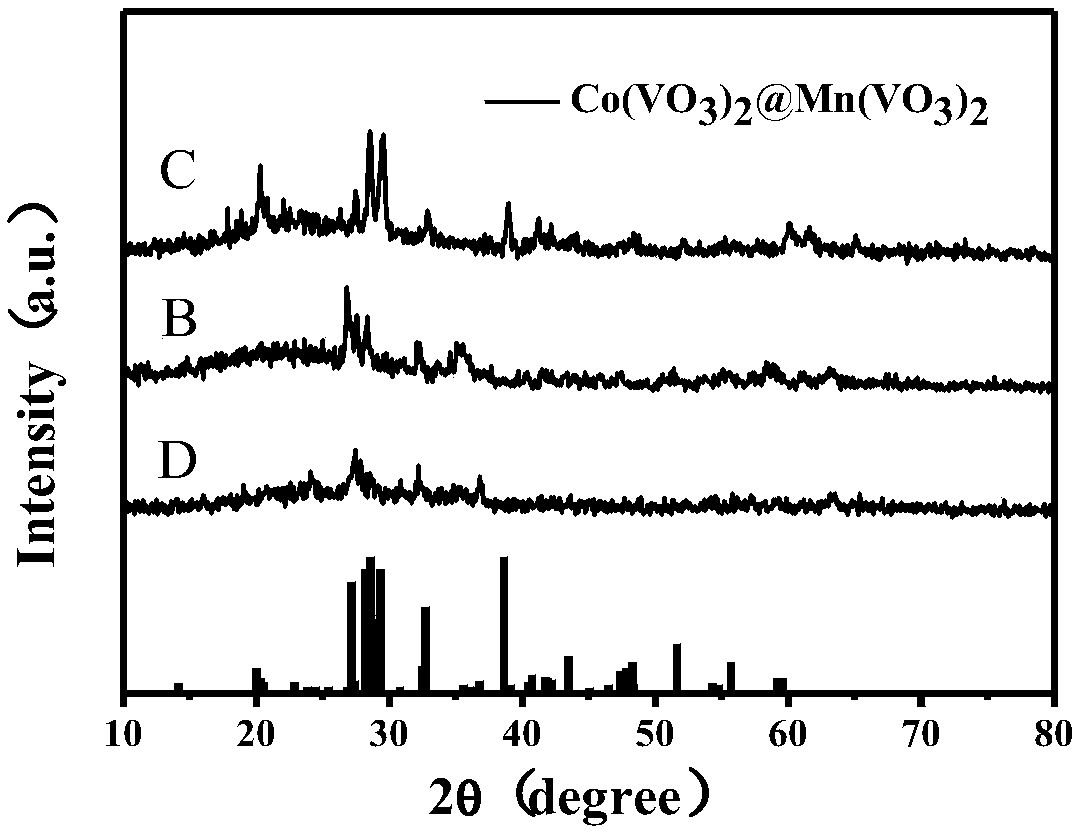

[0061] Embodiment 1 solid unidirectional pencil point Co (VO 3 ) 2 -Mn(VO 3 ) 2 preparation of

[0062] Solid unidirectional pencil head structure Co(VO 3 ) 2 -Mn(VO 3 ) 2 The material preparation method comprises the following steps:

[0063] (1) NH 4 VO 3 Add deionized water at 70-90°C, and continue to stir for 5-10 minutes, the solution turns light yellow-green;

[0064] (2) Add CO(NH 2 ) 2 Mix with NaOH, LiOH, KOH one of the strong bases, and keep stirring until it is completely dissolved. When the above mixture is added, the concentration of the mixture in the solution is 0.05-0.08molL -1 , where CO(NH 2 ) 2 The molar number is the same as that of the above-mentioned strong base;

[0065] (3) Add the cobalt salt to the above solution, and keep stirring until the solution turns transparent reddish brown, wherein the Co:V molar ratio ranges from 1:3 to 1:5; preferably, the cobalt salt is CoCl 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O, Co(Ac) 2 4H 2 O etc.;

[00...

Embodiment 2

[0075] Embodiment 2 solid two-way pencil head Co (VO 3 ) 2 -Mn(VO 3 ) 2 preparation of

[0076] Solid two-way pencil head structure Co(VO 3 ) 2 -Mn(VO 3 ) 2 The material preparation method comprises the following steps:

[0077] (1) NH 4 VO 3 Add deionized water at 70-90°C, and continue to stir for 5-10 minutes, the solution turns light yellow-green;

[0078] (2) Add one of NaOH, LiOH, and KOH to the solution, and continue to stir until it is completely dissolved. The concentration of one of the strong bases of NaOH, LiOH, and KOH in the solution is 0.02-0.05molL -1 ;

[0079] (3) Add the cobalt salt to the above solution, and keep stirring until the solution turns transparent reddish brown, wherein the Co:V molar ratio ranges from 1:3 to 1:5; preferably, the cobalt salt is CoCl 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O, Co(Ac) 2 4H 2 O etc.;

[0080] (4) Add MnCl to the above solution 2 ·5H 2 O, keep stirring until completely dissolved, wherein the molar ratio of Mn...

Embodiment 3

[0089] Embodiment 3 Hollow two-way pencil point Co (VO 3 ) 2 -Mn(VO 3 ) 2 preparation of

[0090] Hollow two-way pencil head structure Co(VO 3 ) 2 -Mn(VO 3 ) 2 The material preparation method comprises the following steps:

[0091] (1) NH 4 VO 3 Add deionized water at 70-90°C, and continue stirring for 5-10 minutes, the solution turns light yellow-green;

[0092] (2) Add one of the strong bases NaOH, LiOH, KOH to the solution, and continue to stir until it is completely dissolved. The concentration of one of the strong bases added in NaOH, LiOH, and KOH in the solution is 0.05-0.08 moL -1 ;

[0093] (3) Add the cobalt salt to the above solution, and keep stirring until the solution turns transparent reddish brown, wherein the Co:V molar ratio ranges from 1:3 to 1:5; preferably, the cobalt salt is CoCl 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O, Co(Ac) 2 4H 2 O etc.;

[0094] (4) Add MnCl to the above solution 2 ·5H 2 O, keep stirring until completely dissolved, where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com