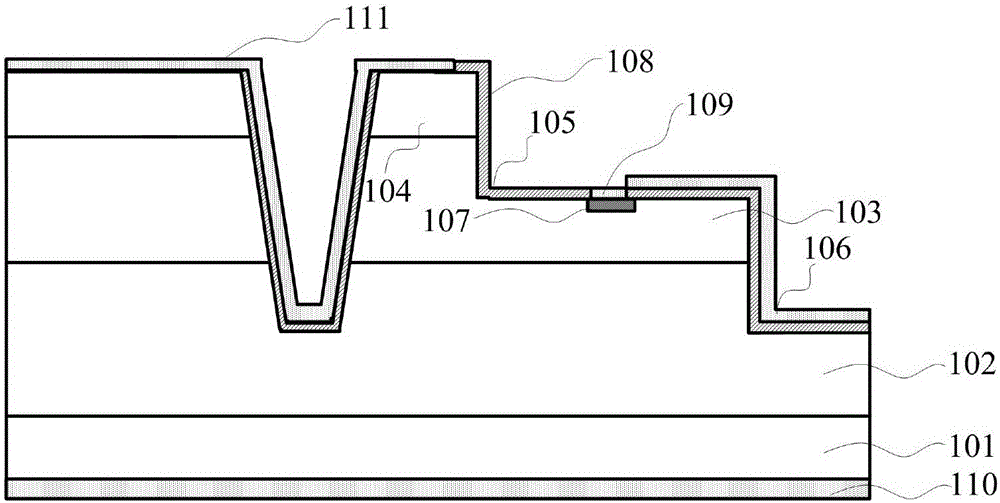

Silicon carbide bipolar transistor based on active region trench structure and manufacturing method thereof

A bipolar transistor and active region technology, applied in the field of microelectronics, can solve problems such as low breakdown voltage, achieve the effects of improved breakdown voltage, compatible manufacturing process, improved base transfer efficiency and current gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In the first step, the N − collector region 102 is epitaxially grown on the N+ substrate 101 . Specifically, such as Figure 2A As shown, the N+ substrate 101 is firstly cleaned by RCA standard; and then the front surface of the N+ substrate 101 is epitaxially grown with a thickness of 6 μm and a nitrogen ion doping concentration of 3×10 15 cm-3 N-collector region 102 .

[0044] It should be noted that the growth conditions of the N-collector region 102 are: the epitaxial process conditions are: temperature 1600°C, pressure 100mbar, reaction gas is silane and propane, carrier gas is pure hydrogen, and impurity source is liquid nitrogen.

[0045] It should be noted that the RCA standard cleaning method was first created by Kern and Puotinen in the RCA laboratory of N.J.Princeton in 1965, and thus got its name. RCA is a typical wet chemical cleaning method that is still the most commonly used. The cleaning method mainly includes the following cleaning solutions.

[004...

Embodiment 2

[0071] In step 1, epitaxially grow the N− collector region 102 on the N+ substrate 101 . Specifically, such as Figure 2A As shown, the N+ substrate 101 is firstly cleaned by RCA standard; then, on the front of the N+ substrate 101, the epitaxial growth thickness is 6.5 μm, and the nitrogen ion doping concentration is 6×10 15 cm -3 N-collector region 102 .

[0072] It should be noted that the growth conditions of the N-collector region 102 are as follows: the temperature is 1600° C., the pressure is 100 mbar, the reaction gas is silane and propane, the carrier gas is pure hydrogen, and the impurity source is liquid nitrogen.

[0073] Step 2, growing the base region 103 epitaxially on the N − collector region 102 . Specifically, such as Figure 2B As shown, on the N- collector region 102, the epitaxial growth thickness is 0.7 μm and the doping concentration of aluminum ions is 1×10 17 cm -3 base region 103 .

[0074] It should be noted that the growth process conditions of...

Embodiment 3

[0093] In step A, epitaxially grow the N− collector region 102 on the N+ substrate 101 . Specifically, such as Figure 2A As shown, the N+ substrate 101 is firstly cleaned by RCA standard; then, the epitaxial growth thickness is 7 μm and the nitrogen ion doping concentration is 1×10 16 cm -3 N-collector region 102 .

[0094] It should be noted that the growth conditions of the N-collector region 102 are as follows: the temperature is 1600° C., the pressure is 100 mbar, the reaction gas is silane and propane, the carrier gas is pure hydrogen, and the impurity source is liquid nitrogen.

[0095] In step B, the base region 103 is epitaxially grown on the N − collector region 102 . Specifically, such as Figure 2B As shown, on the N- collector region 102, the epitaxial growth thickness is 0.8 μm and the doping concentration of aluminum ions is 5×10 17 cm -3 base region 103 .

[0096] It should be noted that the growth process conditions of the base region 103 are as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com