High-voltage line outlet structure of electric reactor at voltage of less than or equal to 500kV

A high-voltage outgoing line and reactor technology, applied in the direction of transformers/inductor coils/windings/connections, circuits, electrical components, etc., can solve problems such as low stability and reliability, economical decline, and low manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

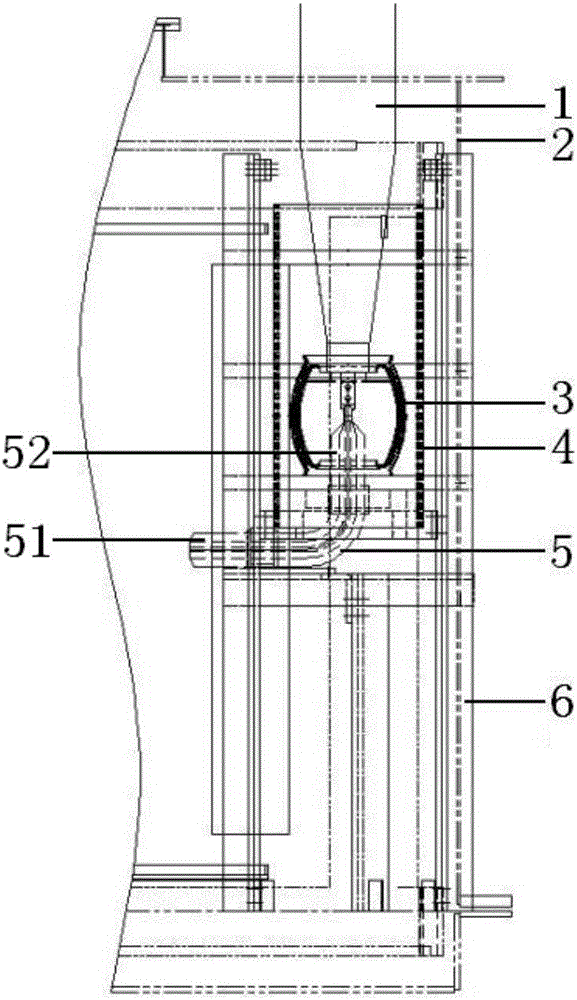

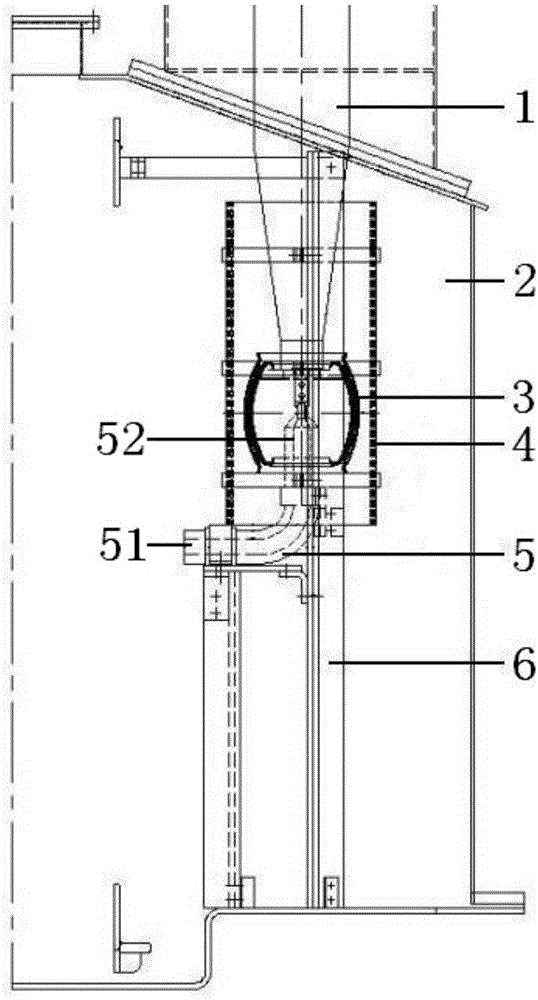

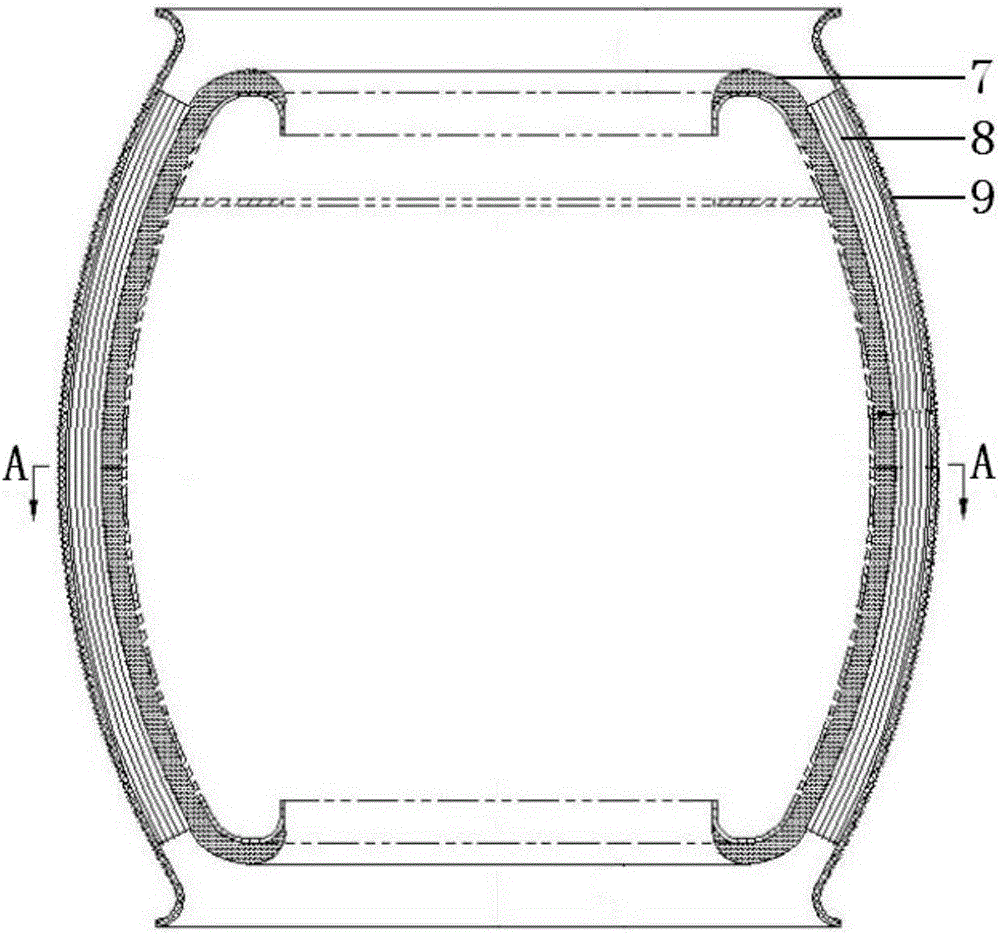

[0021] Such as figure 1 , figure 2 As described above, a high-voltage outlet structure of a reactor of 500kV or below includes a high-voltage phase line 5 and a bushing 1 connected to its outlet end, and the high-voltage phase line 5 includes a horizontal part 51 of a high-voltage phase line and a vertical part of a high-voltage phase line 52. The outer side of the vertical part of the high-voltage phase line 52 is nested with a pressure equalizing ball insulation assembly 3, and the outer side of the pressure equalization ball insulation assembly 3 is nested with an insulating paper tube assembly 4. The live part of the bushing 1 is nested in a 1200mm long Inside the insulating paper tube assembly 4, and the lower end of the insulating paper tube assembly 4 extends to about 20 mm above the horizontal part 51 of the high-voltage phase line, and the lower end of the equalizing ball insulation assembly 3 extends to about 300 mm from the center of the horizontal part 51 of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com