Double-inlet and double-outlet steel ball coal mill screw propeller support rod loading device

A steel ball coal mill and screw propeller technology, applied in the field of coal mill accessories, can solve the problems of double-inlet and double-outlet steel ball coal mill support rod breakage, etc., to avoid shear force, avoid breakage, and compensate for manufacturing and installation effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

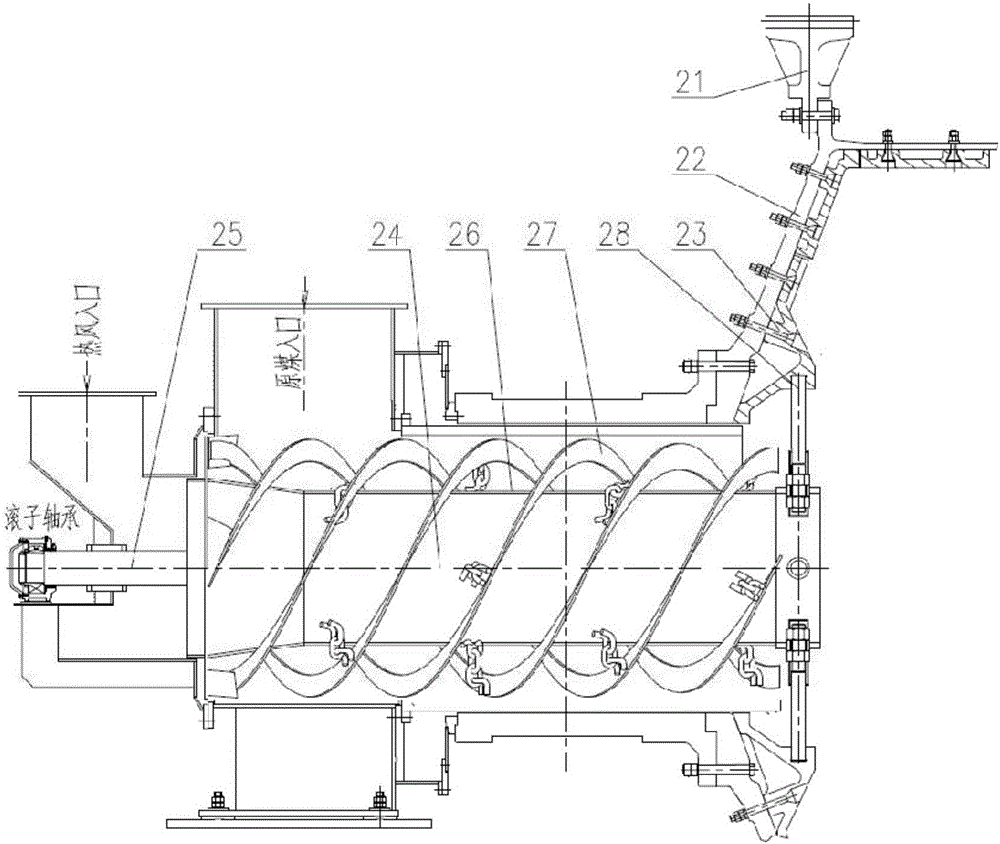

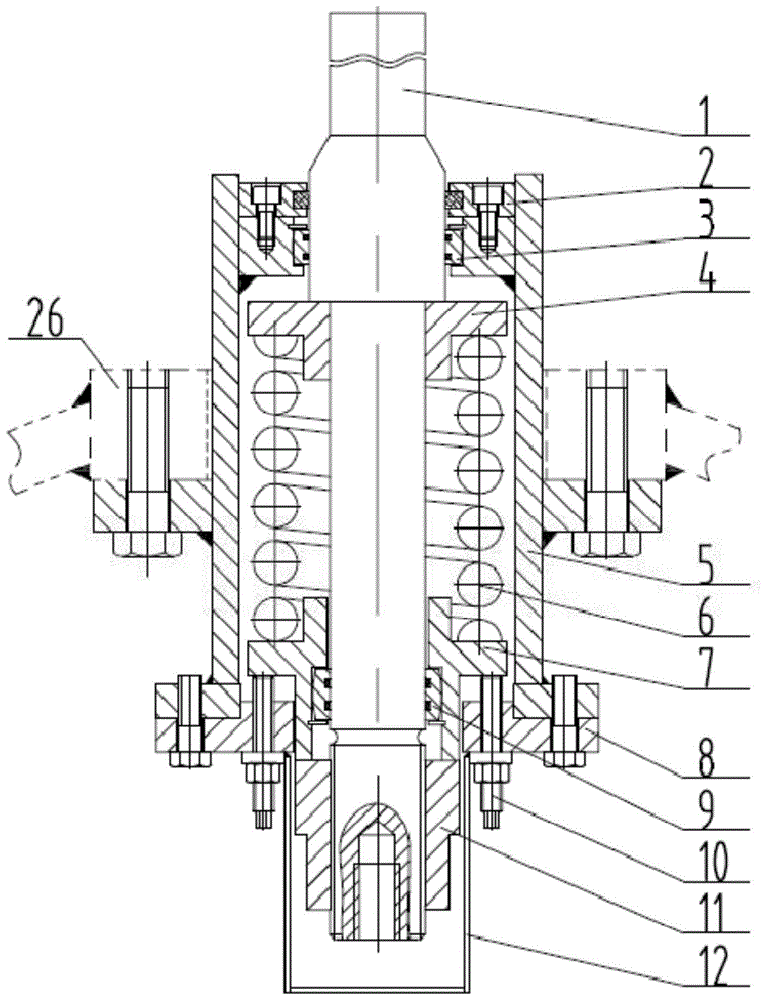

[0043] Such as figure 2 As shown, the double-inlet and double-outlet steel ball mill screw propeller support rod loading device of the present invention includes a support rod 1, and the support rod 1 is in the shape of a ladder; The seat cover 8 forms a cavity; the upper end of the support rod 1 (the left end in the figure) is fixedly connected to the lining plate 23, the outside of the spring seat 5 is fixedly connected to the central tube 26, and the lower end of the support rod 1 extends into the central tube 26;

[0044] The spring 6 is sleeved on the support rod 1, and the spring 6, the spring upper pressure sleeve 4, and the spring lower pressure sleeve 7 are located in the cavity formed by the spring seat 5;

[0045] The upper end of the spring seat 5 is connected to the large end of the support rod 1 through the copper sleeve 3 on the double arc surface; the outer side of the spring seat 5 is provided with a sealing cover 2, and the sealing cover 2 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com