A device for laser cladding treatment of plates

A laser cladding treatment and plate technology, applied in metal material coating process, coating and other directions, can solve problems such as can not fundamentally solve the problem, manual operation is random, difficult to operate with high precision, etc. The effect of strong flexibility, simple and lightweight structure, and reduced labor requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

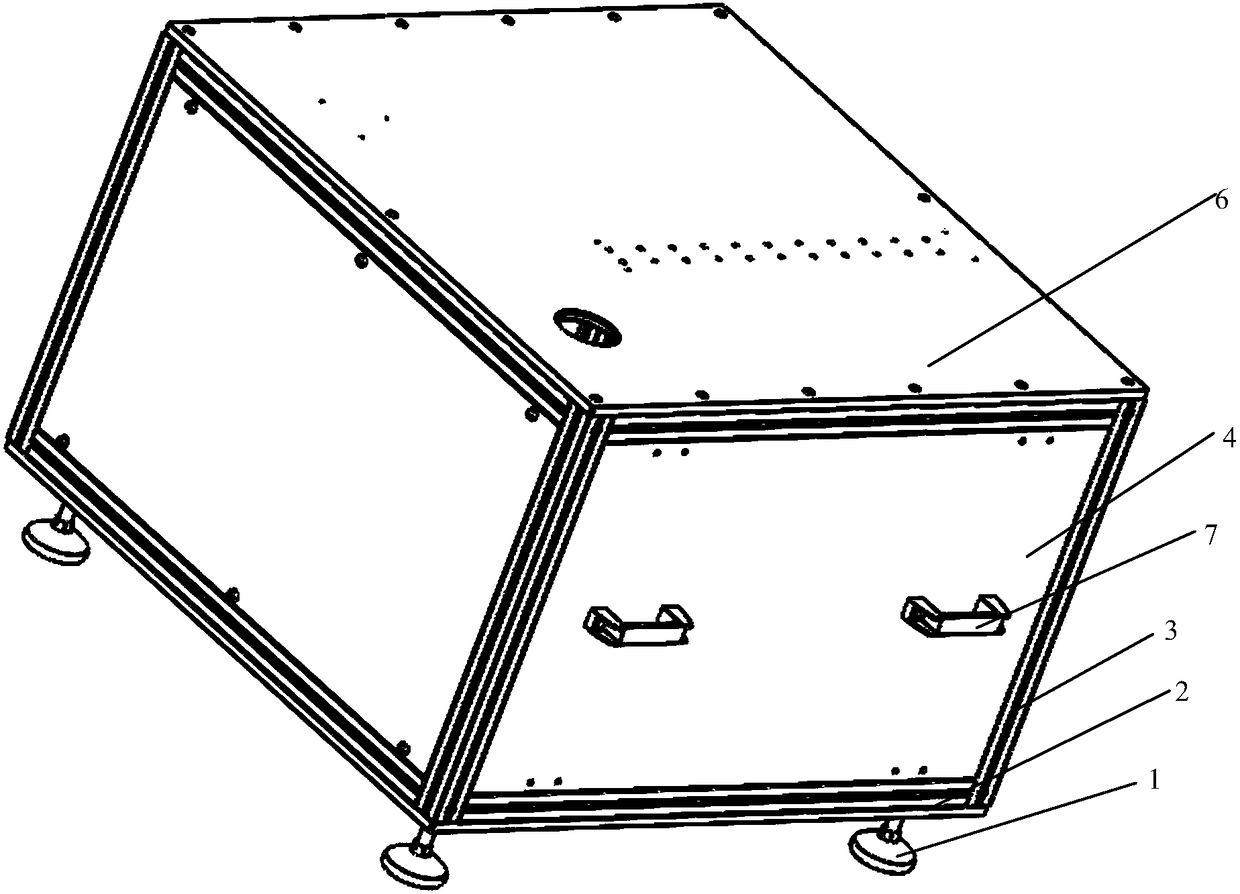

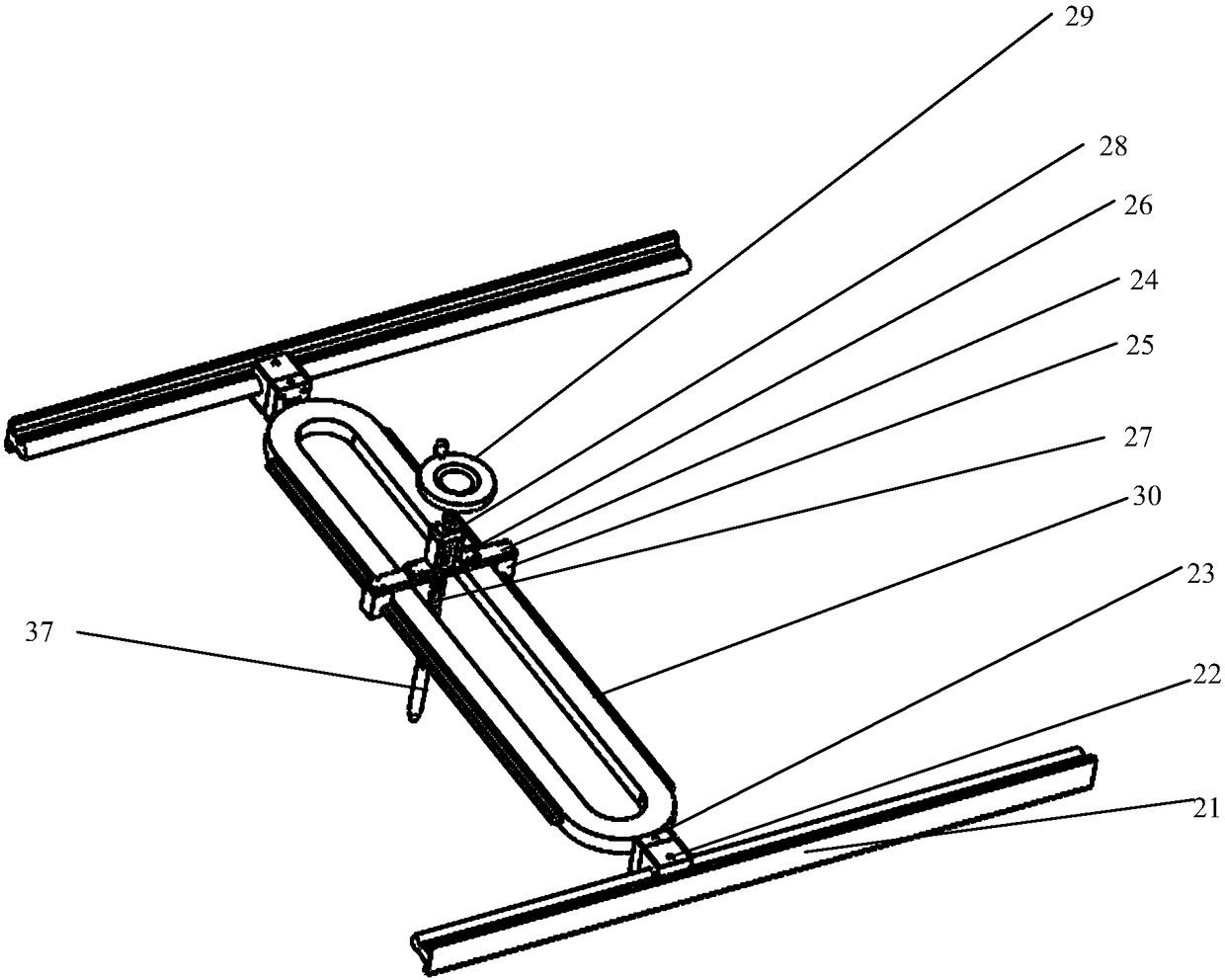

[0024] A device for laser cladding treatment of panels provided by the present invention includes a lower cabinet body 32, a cross electric cylinder, a rotating mechanism 34, a laser cladding mechanism 35, a vision system 36 and an upper support frame.

[0025] The cross electric cylinder comprises a horizontal electric cylinder 8, a vertical electric cylinder 33 and a slide block 12; the cross electric cylinder is fixed on the flat plate 6 of the lower cabinet 32 by screws, and the slide block 12 is fixed on the Above the cross electric cylinder; the rotating mechanism 34 includes a base plate 13, a support column 14, a third driving device 15, an expansion sleeve 16, a workpiece placement tray 19 and a workpiece placement box 17; the base plate 13 is fixed on the On the slider 12, the support column 14 is screwed on the base plate 13, and the workpiece placement bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com