Process for preparing biomass briquette coal by dehydrating and upgrading lignite

A technology of biomass and lignite, applied in the direction of biofuel, waste fuel, petroleum industry, etc., can solve the problems of high production cost, low dehydration efficiency of lignite, and low utilization rate of biomass energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

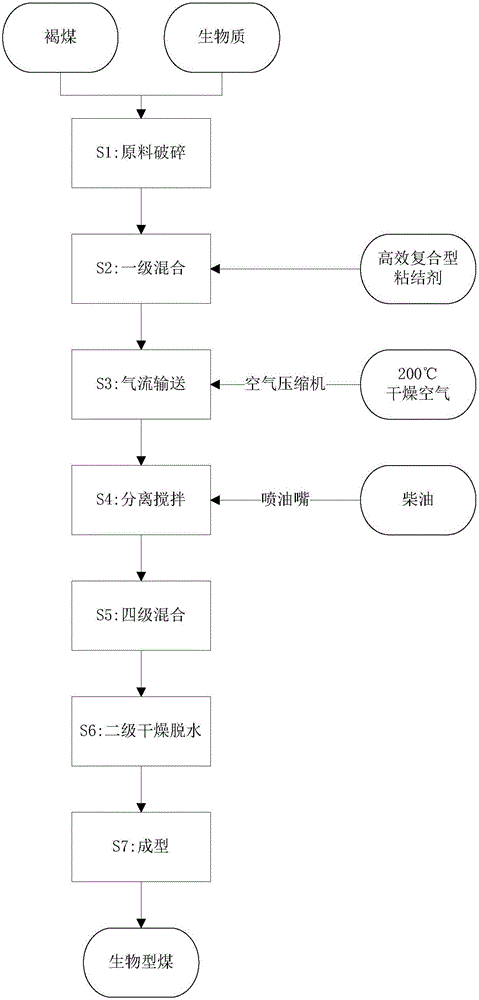

[0030] A process for preparing biomass briquettes by dehydration and upgrading of lignite, using the preparation process to prepare biomass briquettes as follows:

[0031] S1. Raw material crushing operation: select lignite with a moisture content of 30%, and use a reversible impact hammer crusher to break and decompose the lignite through the two-end grinding process. After crushing and decomposing, the lignite particle size is 5mm; The mixture of corn stalks and cattle and sheep manure with less than 25% is crushed and decomposed, and the particle size of the crushed and decomposed particles is 7mm.

[0032] S2, primary mixing operation: mix lignite particles and biomass particles according to the mass ratio of 8:2, and then mix with a high-efficiency composite binder with a mass ratio of 10% of the mixture, feed the mixture into the screw feeder for primary mixing and Transport it outward; in addition, crush the wheat straw to a particle size of 7mm, add it to a 1% sodium h...

Embodiment 2

[0040] S1. Raw material crushing operation: select lignite with a moisture content of 30%, and use a reversible impact hammer crusher to break and decompose the lignite through the two-end grinding process. After crushing and decomposing, the lignite particle size is 5mm; The mixture of corn stalks and cattle and sheep manure with less than 25% is crushed and decomposed, and the particle size of the crushed and decomposed particles is 7mm.

[0041]S2, primary mixing operation: mix lignite particles and biomass particles according to the mass ratio of 7:3, and then mix with a high-efficiency composite binder with a mass ratio of 10% of the mixture, feed the mixture into the screw feeder for primary mixing and Transport it outward; in addition, crush the wheat straw to a particle size of 7mm, add it to a 1% sodium hydroxide solution at a mass ratio of 12%, and add 0.5% calcium chloride, 0.7% calcium hydroxide , heated at 76° C. for 2 h and filtered the viscous substance obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com