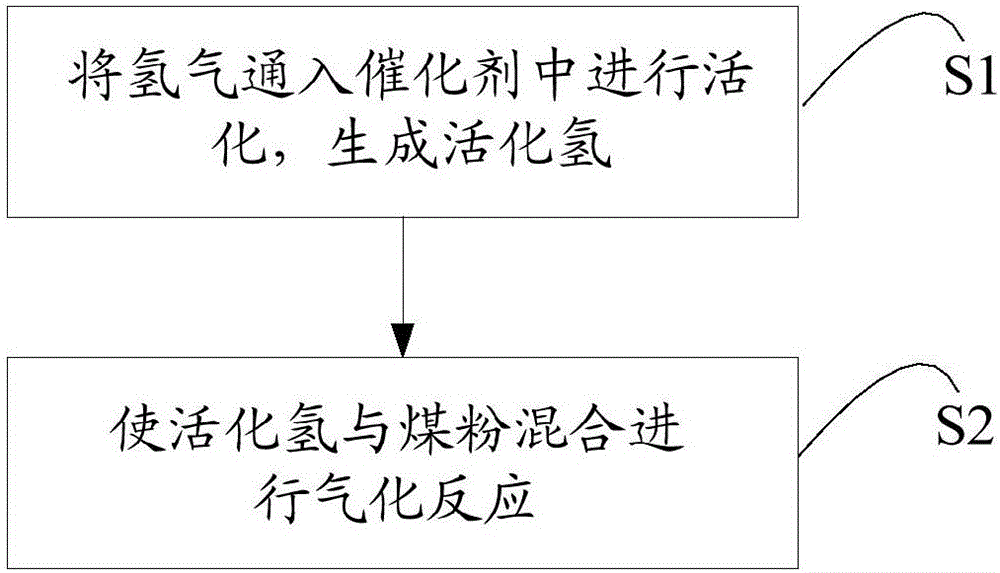

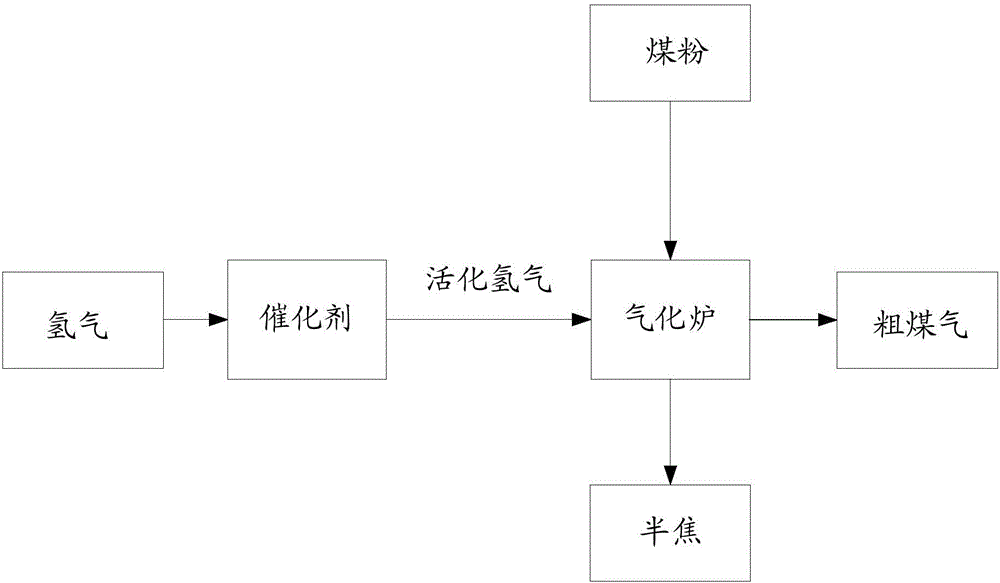

Coal hydrogenation gasification method

A technology of coal hydrogenation gasification and hydrogen, which is applied in the field of coal gasification, can solve the problems of low yield of methane and light oil products, and achieve the effect of increasing the hydrogenation degree and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add a specific surface area of 160m to the catalyst chamber 2 / g, the pore volume is 0.3cm 3 / g, α-Al with a pore size of 4nm 2 o 3 Supported Ni-based catalysts (Ni accounted for α-Al 2 o 3 The weight fraction is 4wt%), and preheated to 450 ° C, hydrogen at 100Nm 3 The flow rate of / h is passed into the catalyst chamber to carry out catalytic activation reaction with the catalyst, wherein, the weight of the catalyst is 1kg, and the pressure of the catalytic activation reaction is 6MPa; Coal hydrogasification reaction, in which the time required for the activated hydrogen to be transported to the pulverized coal is 0.1ms, the weight ratio of hydrogen to pulverized coal is 0.3, and the product is half Coke and crude gas, the crude gas is separated, purified, washed and deoiled to obtain a synthesis gas with a methane content higher than 45% and a light oil product with a dry basis yield greater than 11%.

Embodiment 2

[0040] Add a specific surface area of 260m to the catalyst chamber 2 / g, the pore volume is 0.6cm 3 / g, α-Al with a pore size of 6nm 2 o 3 Supported Ni-based catalysts (Ni accounted for α-Al 2 o 3 The weight fraction is 11wt%), and preheated to 650 ° C, hydrogen at 460Nm 3 The flow rate of / h is passed into the catalyst chamber to carry out catalytic activation reaction with the catalyst, wherein, in the catalytic reaction, the weight of the catalyst is 0.58kg, and the pressure of the catalytic activation reaction is 6MPa; the activated hydrogen is passed into the gasifier , coal hydrogasification reaction with pulverized coal, in which the time required for the activated hydrogen to be transported to pulverized coal is 0.75ms, the weight ratio of hydrogen to pulverized coal is 0.4, and the reaction is carried out at a temperature of 600°C and a pressure of 6MPa After 4s, the product semi-coke and crude gas are obtained, and the crude gas is separated, purified, washed ...

Embodiment 3

[0042] Add a specific surface area of 350m to the catalyst chamber 2 / g, the pore volume is 0.9cm 3 / g, α-Al with a pore size of 9nm 2 o 3 Supported Ni-based catalysts (Ni accounted for α-Al 2 o 3 The weight fraction is 18wt%), and preheated to 850 ° C, hydrogen at 560Nm 3 The flow rate of / h is passed into the catalyst chamber to carry out catalytic activation reaction with the catalyst, wherein the weight of the catalyst is 0.7kg, and the pressure of the catalytic activation reaction is 7MPa; the activated hydrogen is passed into the gasifier, and the pulverized coal Coal hydrogasification reaction is carried out, in which the time required for the activated hydrogen to be transported to the pulverized coal is 1.5ms, the weight ratio of hydrogen to pulverized coal is 0.5, and the product is obtained after the reaction at a temperature of 700°C and a pressure of 7MPa for 6s Semi-coke and crude gas, the crude gas is separated, purified, washed and deoiled to obtain syng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com