Crude oil demulsifying agent and preparation method thereof

A crude oil demulsifier and demulsifier technology, applied in chemical dehydration/demulsification, hydrocarbon oil treatment, petroleum industry, etc., can solve problems such as difficult separation, unsatisfactory dehydration effect, cumbersome synthesis method, etc., and achieve clear water quality , crude oil has a wide range of adaptability, and the synthesis method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

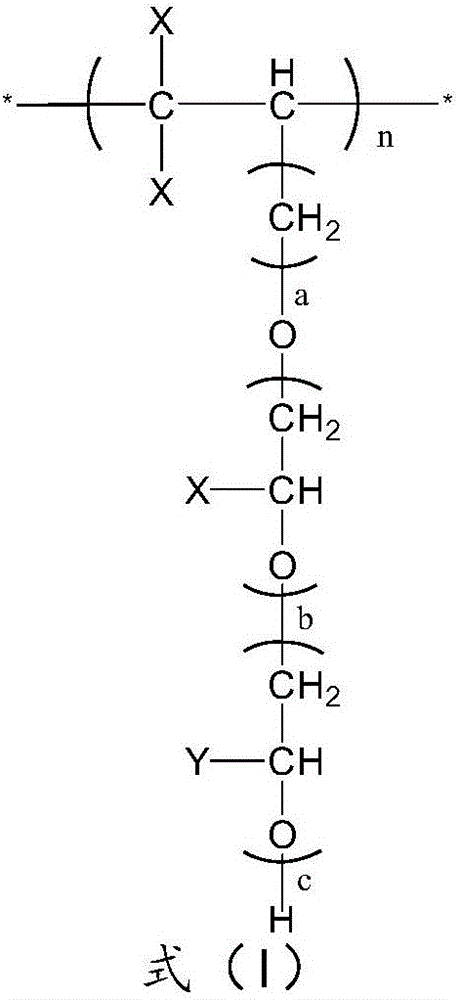

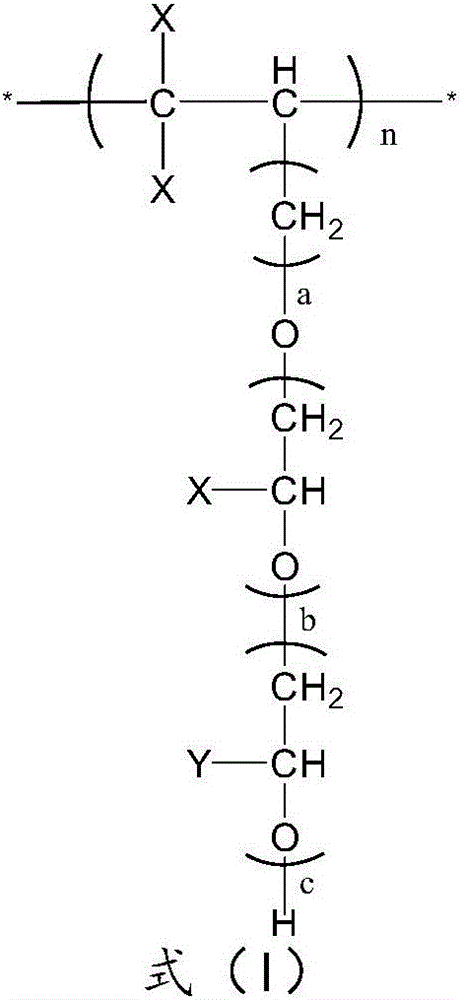

Image

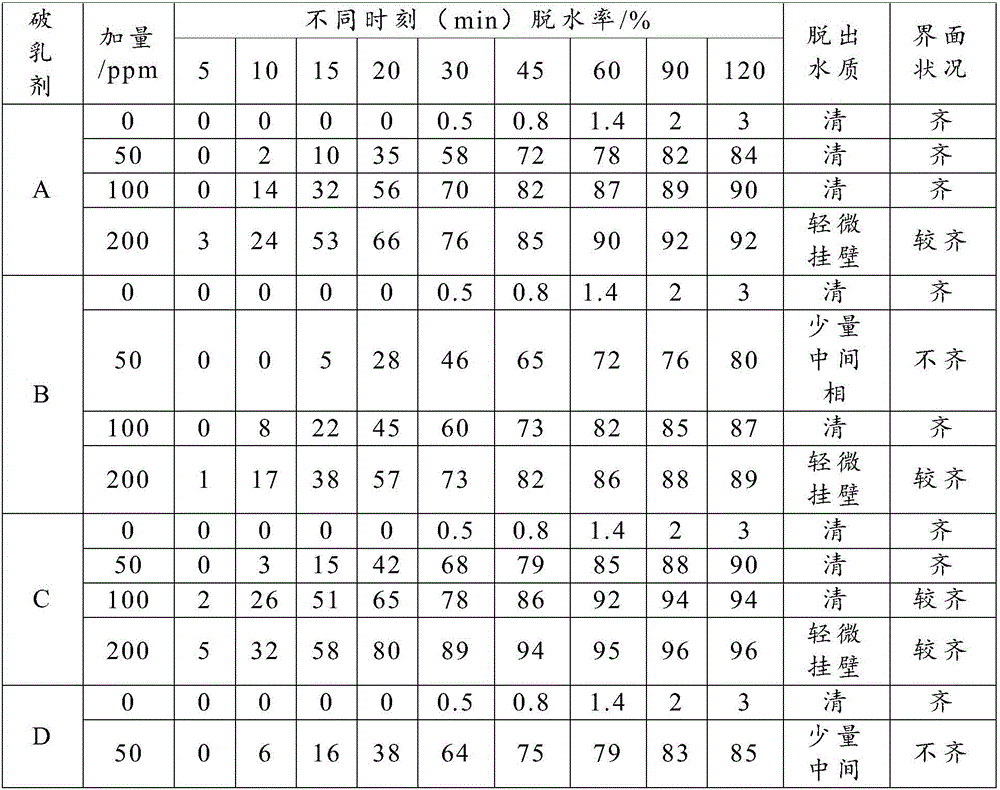

Examples

preparation example Construction

[0030] The embodiment of the present invention also provides a preparation method of the crude oil demulsifier as described in the above embodiment, comprising the following steps: adding polyoxyethylene polyoxypropylene ether of unsaturated alcohol, initiator and solvent into the reaction vessel, Under the protection of nitrogen, the crude oil demulsifier is obtained by initiating polymerization under the condition that the reaction temperature is 80°C-110°C and the reaction time is 3-8h.

[0031] The above-mentioned embodiment provides a kind of preparation method of crude oil demulsifier, wherein, polyoxyethylene polyoxypropylene ether macromonomer of unsaturated alcohol is obtained by initiating polymerization under the action of solvent and initiator, in the above-mentioned preparation method , in order to avoid the impact of the ambient atmosphere on the reactants, the whole reaction is operated under the protection of an inert gas, preferably nitrogen, and the reaction t...

Embodiment 1

[0038] Put 1 mol of hexenol into the autoclave, add AlCl 3 As a catalyst, vacuumize, N 2 Purge three times, gradually raise the temperature to 110°C, continuously feed propylene oxide and ethylene oxide, and keep the reaction pressure at 0.25MPa. After the feed reaction is completed, vacuumize to remove the reaction residue, and add acetic acid to neutralize, that is Hexenol polyoxypropylene polyoxyethylene ether can be obtained.

[0039] Add hexenol polyoxypropylene polyoxyethylene ether into the reaction container, and then add 80% butyl acetate solvent into it, fill it with nitrogen for protection, raise the temperature to 80°C, and slowly add 3% peroxide The initiator of benzoyl, the temperature is lowered after the polymerization reaction for 8 hours, and the demulsifier A is obtained.

Embodiment 2

[0041] Put 1mol of butenol into the autoclave, add Ca(OH) 2 As a catalyst, vacuumize, N 2 Purge three times, gradually raise the temperature to 140°C, continuously feed propylene oxide, and keep the reaction pressure at 0.3MPa. After the feed reaction is completed, vacuumize to remove the reaction residue, add acetic acid to neutralize, and you can get butenol polyoxyethylene polyoxypropylene ether.

[0042] Add butenyl alcohol polyoxyethylene polyoxypropylene ether into the reaction container, then add xylene solvent with a weight ratio of 50%, fill it with nitrogen for protection, raise the temperature to 90°C, and slowly add 1% azobis The initiator of isobutyronitrile, the temperature is lowered after the polymerization reaction for 4 hours, and the demulsifier B is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com