Lubricating oil vacuum microwave water removing device

A technology of vacuum microwave and dehydration device, applied in lubricating composition, ion exchange treatment device, ion exchange regeneration and other directions, can solve problems such as maintenance and repair user difficulties, achieve convenient and fast transportation and movement, reduce equipment size, and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

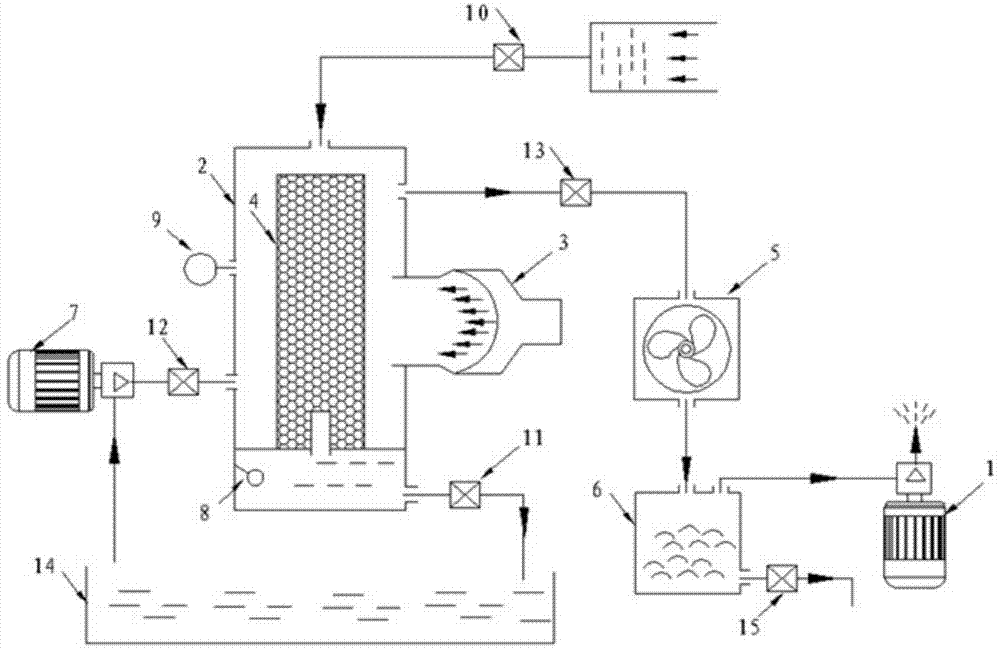

[0017] The specific embodiment of the present invention is shown in the figure. The lubricating oil vacuum microwave dehydration device has a vacuum pump 1, a filter tank body 2, a microwave magnetron 3, a polymer water-absorbing filter element 4 installed in the filter tank body 2, an air condenser 5, a water collection tank 6, an oil delivery pump 7 and Electrical control system composition. The oil delivery pump 7 extracts the lubricating oil to be dehydrated from the user's oil tank 14 and inputs it into the filter tank body 2, and returns to the user's oil tank after being adsorbed and dehydrated by the polymer water-absorbing filter element 4 . After the polymer water-absorbing filter element 4 is saturated with water, the differential pressure transmitter 9 sends a signal, the oil delivery pump 7 stops, the system terminates the lubricating oil dehydration process, and starts the filter element dehydration process. After the dehydration process of the filter element is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com