Graphite foam and preparation method thereof

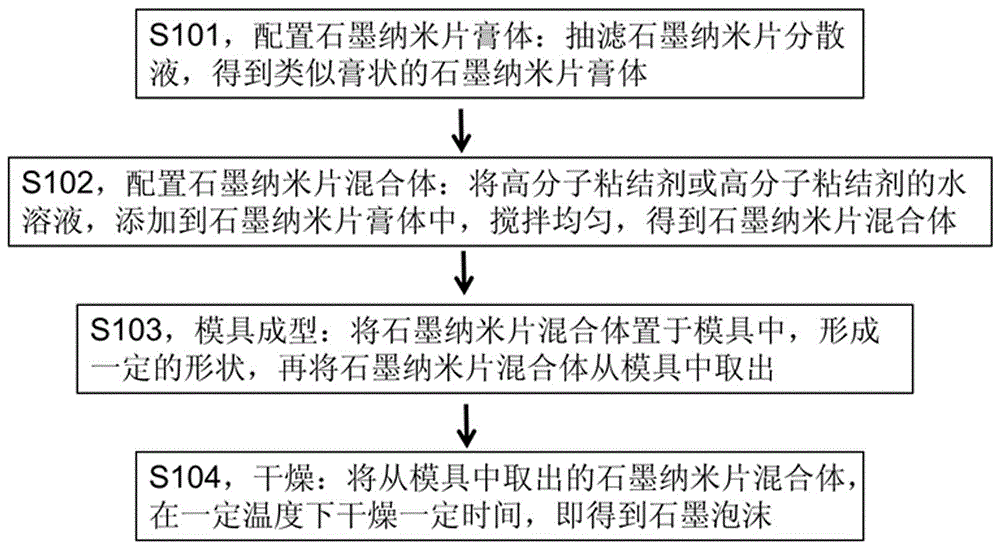

A technology of graphite foam and graphite nanosheets, which is applied in the field of materials, can solve problems such as complex processes, and achieve the effects of uniform pore distribution, low resistance, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1. S101, configure graphite nanosheet paste: disperse 22g of expanded graphite in 2kg of water and ethanol mixture, the mass ratio of water and ethanol is 1:9, add 1g of carboxymethylcellulose, and stir for 0.5 hours , and ultrasonically exfoliate the mixed solution for 10 hours with an ultrasonic pulverizer to obtain a dispersion of graphite nanosheets. The graphite nanosheet dispersion was suction filtered to obtain a mud-like graphite nanosheet paste, wherein the graphite nanosheet accounted for 4% by mass of the graphite nanosheet paste.

[0052] 2. S102, preparing graphite nanosheet mixture: dissolving 0.4g polyethylene glycol in 199.6g water, then adding to 200g graphite nanosheet paste obtained in step S101, stirring evenly to obtain graphite nanosheet mixture.

[0053] 3. S103, mold forming: the graphite nanosheet mixture obtained in step S102 is placed in molds of various shapes to form a certain shape, and then the graphite nanosheet mixture is taken out from ...

Embodiment 2

[0057] 1. S101, configure graphite nanosheet paste: disperse 60g of graphite nanosheets in a mixture of 2 kg of water and ethanol, the mass ratio of water and ethanol is 9:1, add 0.21g of polyvinylpyrrolidone, stir for 30 hours, a dispersion of graphite nanosheets was obtained. The nanosheet dispersion was suction-filtered to obtain a mud-like graphite nanosheet paste, wherein the mass percentage of graphite nanosheets in the graphite nanosheet paste was 12%.

[0058] 2. S102, preparing the graphite nanosheet mixture: add 200 g of the aqueous polyurethane solution to the 200 g of the graphite nanosheet paste obtained in step S101, and stir evenly to obtain the graphite nanosheet mixture. The mass content of polyurethane in the aqueous polyurethane solution is 24%.

[0059] 3. S103, mold forming: the graphite nanosheet mixture obtained in step S102 is placed in a mold to form a certain shape, and then the graphite nanosheet mixture is taken out from the mold.

[0060] 4. S104...

Embodiment 3

[0063] 1. S101, configure graphite nanosheet paste: disperse 32g graphite nanosheets in 3 kg of water and ethanol mixture, the mass ratio of water and ethanol is 1:1, and add 1.5g hydroxypropyl methylcellulose element, stirred for 20 hours to obtain a dispersion of graphite nanosheets. The nanosheet dispersion was suction-filtered to obtain a mud-like graphite nanosheet paste, wherein the mass percentage of graphite nanosheets in the graphite nanosheet paste was 9%.

[0064] 2. S102, preparing the graphite nanosheet mixture: add 100 g of the water-based phenolic resin solution to the 200 g of the graphite nanosheet paste obtained in step S101, and stir evenly to obtain the graphite nanosheet mixture. The mass content of the phenolic resin in the aqueous phenolic resin solution is 10%.

[0065] 3. S103, mold forming: the graphite nanosheet mixture obtained in step S102 is placed in a mold to form a certain shape, and then the graphite nanosheet mixture is taken out from the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com