Glaze composition prepared from manganese tungstate as active material and having photocatalytic function and preparation method of glaze composition

A technology of active materials and compositions, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of no reports of photocatalytic functional glazes, no reports of photocatalytic material applications, etc. , to achieve the effect of improving people's living standards, good decoration effect, and promoting the purification of home environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

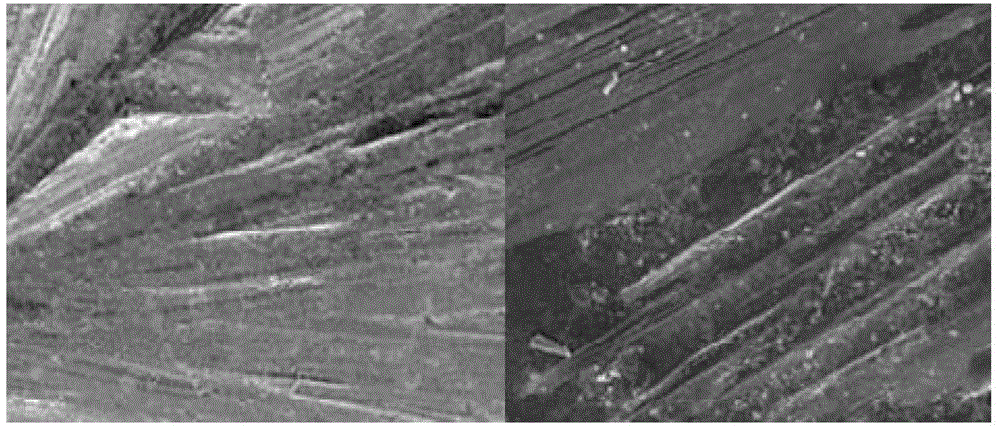

[0039] 1. The method for preparing the glaze proposed by the present invention is simple to operate, and the prepared glaze layer has a good decorative effect on the surface, presents dark green color, beautiful color, strong covering ability, and the glaze surface is flat, smooth, and free of defects such as pinholes;

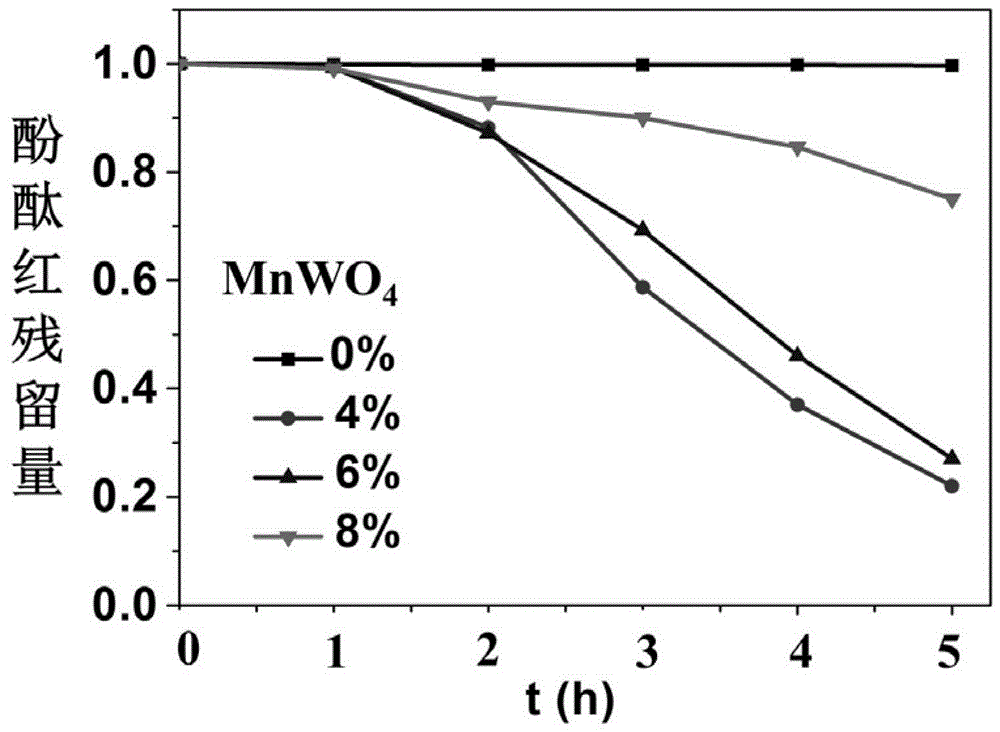

[0040] 2. The glaze prepared by the present invention has a photocatalytic function, and the ceramic glaze can be decomposed to toxic dyes such as phenolphthalein red after 5 hours under light conditions. The decomposition rate of phenolphthalein can reach more than 75%. It plays an obvious role in promoting the purification of the home environment, and is of great significance to improving the quality of the environment and improving people's living standards.

Embodiment 1

[0047] 1) First, mix quartz, potassium feldspar, spodumene, sodium phosphate, MnO, and lithium carbonate raw materials according to the following mass chemical composition ratios. SiO 2 :Al 2 o 3 :P 2 o 5 :MnO:Li 2 O: Na 2 O:K 2 O=25:6:45:2:12:6:12;

[0048] 2) Dry mix and grind the above powders, pass through 40 sieves to get the mixture, put it into a crucible, put it in an electric furnace for 10 minutes at 800°C, keep it at 1000°C for 10 minutes, keep it at 1300°C for 10 minutes, take it out and pour it into water to quench it. frit. Take the frit out of the water, put it into a ball mill after drying, and grind it finely. The ratio of control material (frit): ball: water is 1:1:0.5. After grinding for 3 hours, pass through a 250-mesh sieve and dry for later use. The powder is recorded as material A;

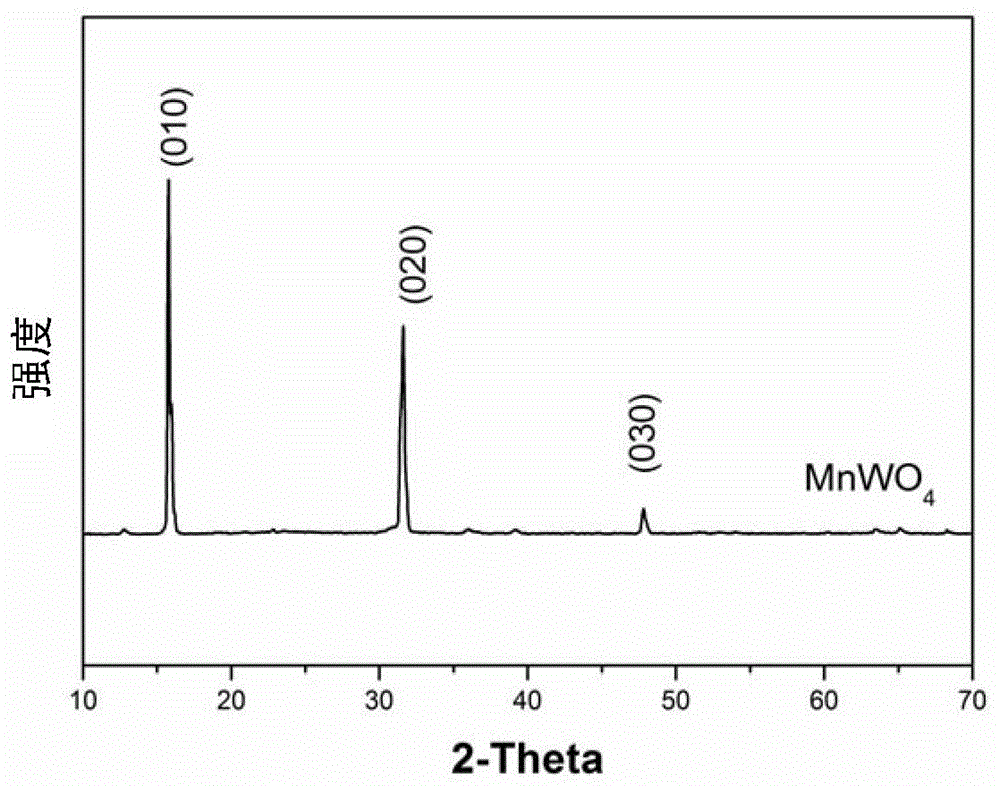

[0049] 3) Manganese chloride and potassium tungstate are used as raw materials, and PEG is used as a template to prepare a solution, in which the concentrations of...

Embodiment 2

[0062] 1) First, mix quartz, potassium feldspar, spodumene, sodium phosphate, MnO, and lithium carbonate raw materials according to the following mass chemical composition ratios. SiO 2 :Al 2 o 3 :P 2 o 5 :MnO:Li 2 O: Na 2 O:K 2 O=25:8:40:1.5:13:7:13;

[0063] 2) Dry mix and grind the above-mentioned powders, pass through 40 sieves to obtain the mixture, put it into a crucible, put it into an electric furnace for 10 minutes at 800°C, keep it at 1000°C for 20 minutes, keep it at 1400°C for 15 minutes, take it out and pour it into water to quench it. frit. Take the frit out of the water, put it into a ball mill after drying, and grind it finely. The ratio of control material (frit): ball: water is 1:1.2:1, pass through a 250-mesh sieve after grinding for 4 hours, and dry for later use. The powder is recorded as material A;

[0064] 3) Prepare a solution with manganese chloride and potassium tungstate as raw materials, and PEG as template agent, in which the concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com