Grain unloading device used for logistics granary

The technology of a grain unloading device and a granary is applied in the field of grain unloading device of a logistics granary, which can solve the problems of high cost, large area and single function, and achieve the effects of low cost, compact and simplified structure, and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (Embodiment 1, grain unloading device)

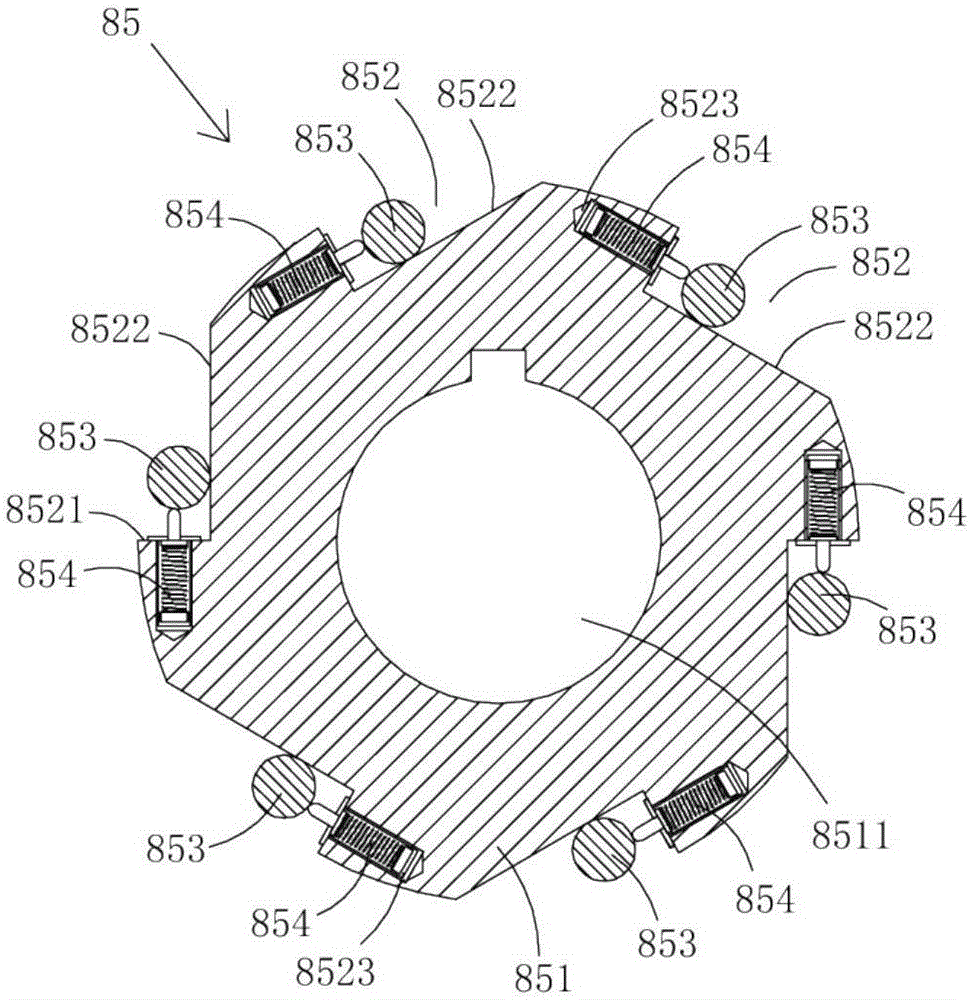

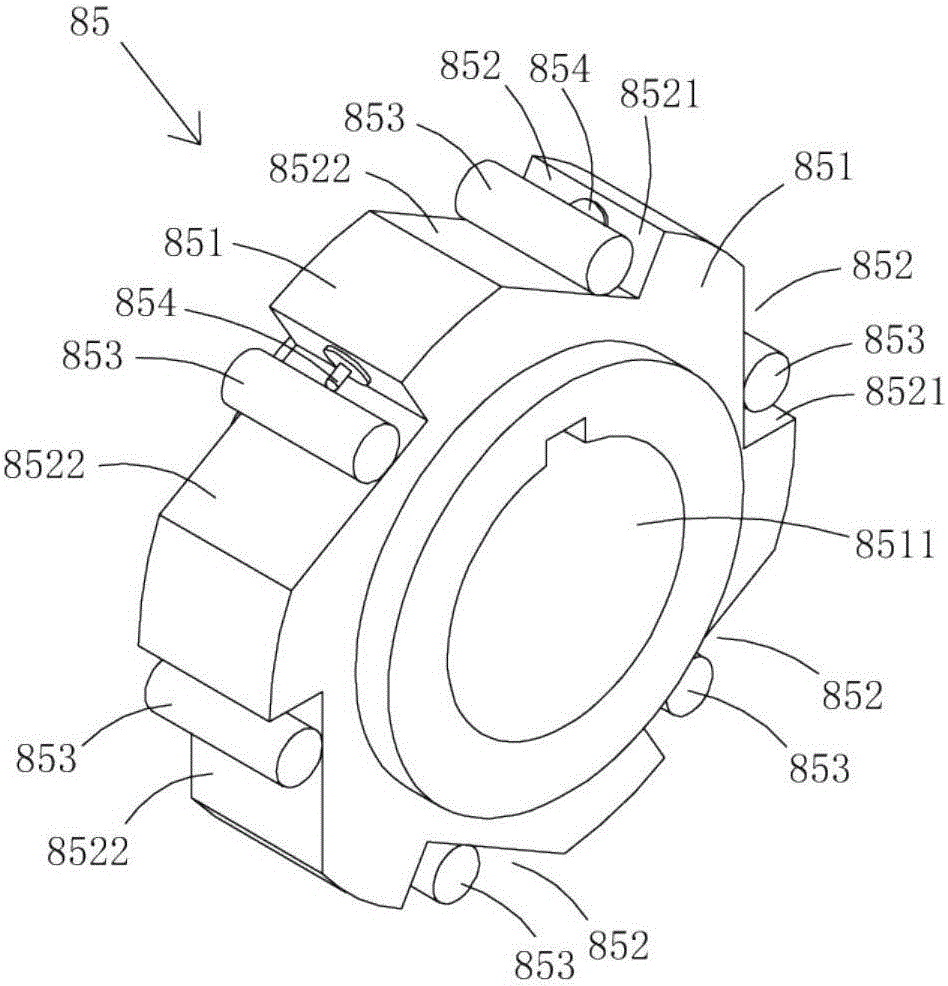

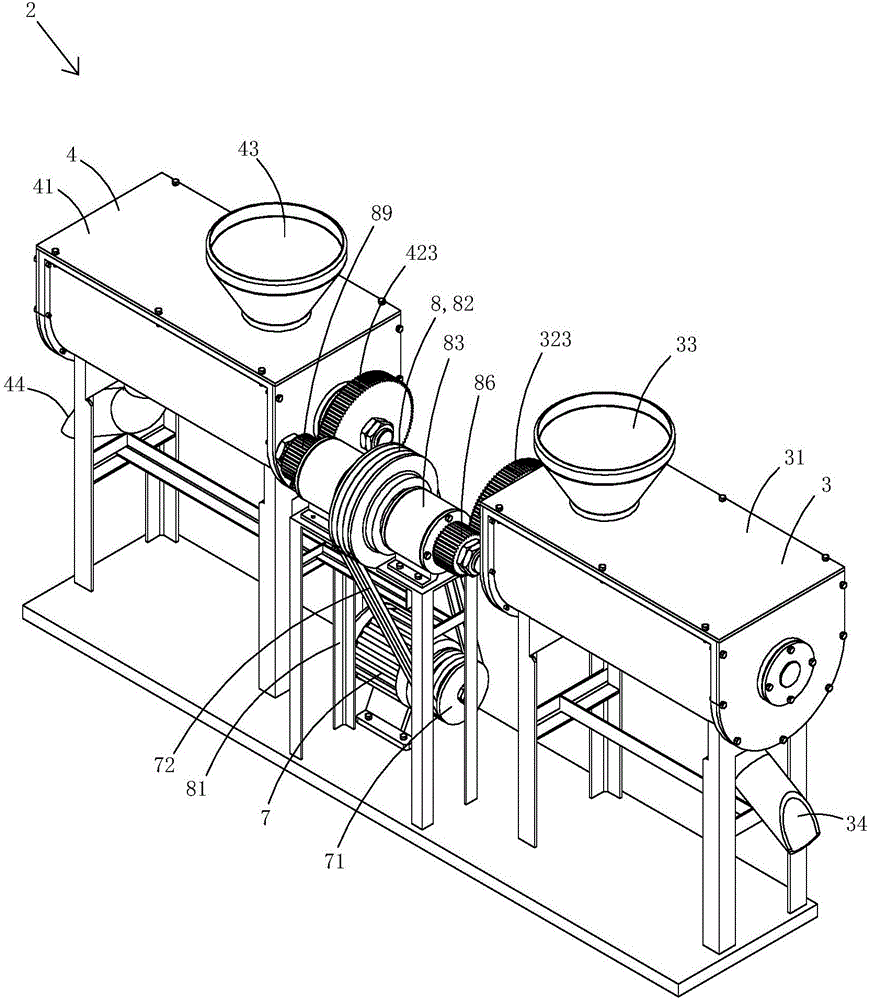

[0035] Figure 1 to Figure 9 One specific embodiment of the invention is shown.

[0036] This embodiment is a grain unloading device for a logistics granary, see Figure 1 to Figure 9 As shown, the grain unloading device 2 includes a first grain unloading box 3, a second grain unloading box 4 and a driving device 5; the first grain unloading box and the second grain unloading box are separated from the two sides of the driving device.

[0037] The first grain unloading box 3 comprises a first box body 31, a first auger 32, a first material inlet 33 arranged on the top wall of the first box body and a first discharge outlet arranged on the bottom wall of the first box body. Pipe 34; the first auger includes a first rotating shaft 321, a first spiral plate 322 fixed on the first rotating shaft and a first driven gear 323 fixed on the first rotating shaft; the main body of the first rotating shaft rotates and is arranged on the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com