Trough solar collector supporting sheet assembling tool and method

A technology for trough collectors and assembly tooling, which is applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problem of inability to guarantee the installation accuracy and light concentrating effect of the collector, the different operating skill levels of workers, and the increase in installation costs. The impact of precision and other issues, to achieve the effect of simple and convenient installation method and process, convenient transportation, and avoid assembly errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

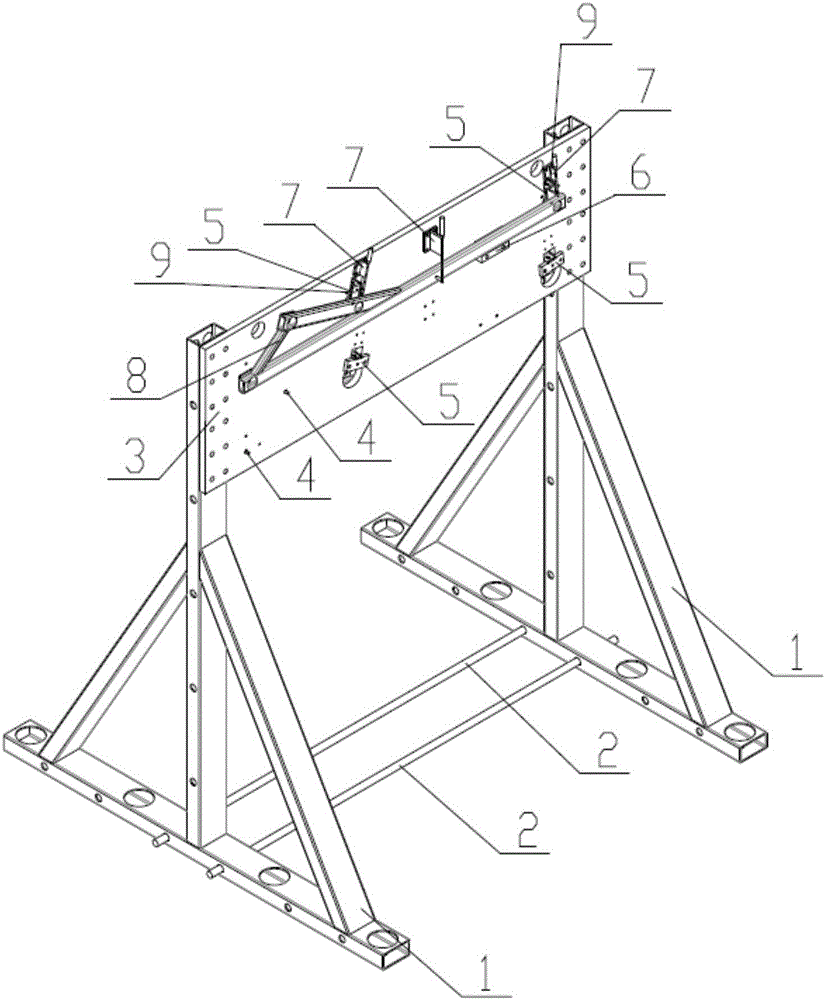

[0022] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

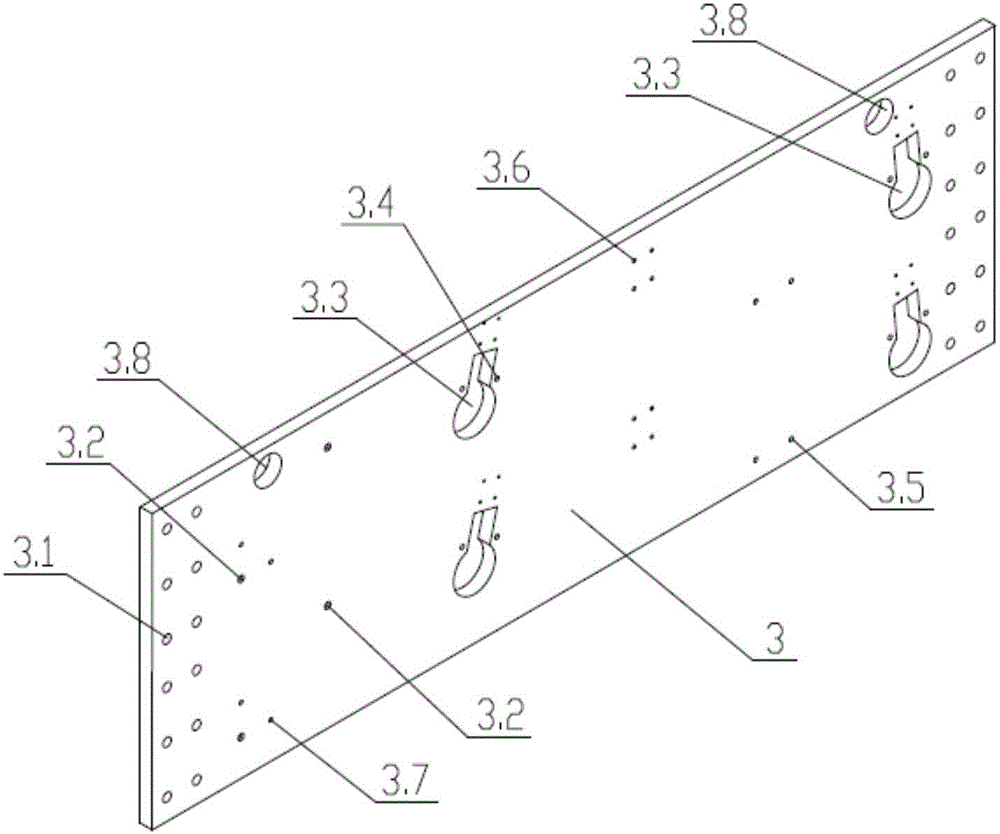

[0023] refer to figure 1 , the preferred embodiment of the present invention provides a trough collector bracket assembly tooling, including a stand 1 and a positioning plate 3, the two sides of the positioning plate 3 are respectively fixed on the upper part of the two stand 1, and the positioning plate 3 is provided with There are some supporting plate positioning blocks 5 for fixing the supporting plate 9, and a cantilever beam positioning block 6 for lifting the cantilever beam 8 and several quick clamps 7 for compressing the cantilever beam 8 and the supporting plate 9 are also provided.

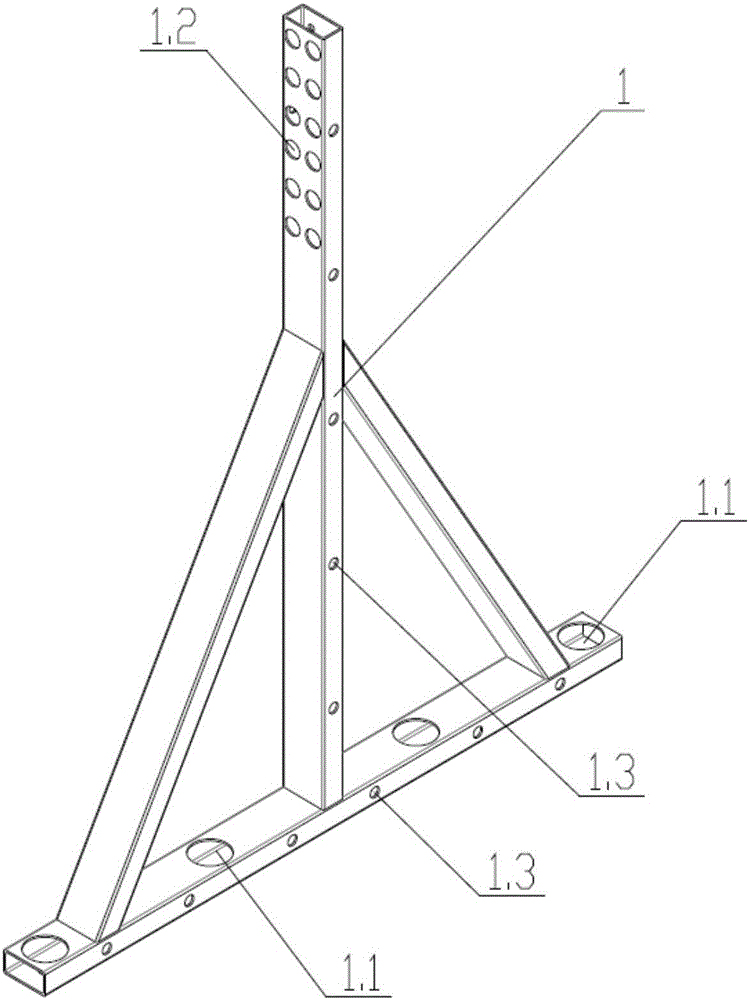

[0024] like figure 2 As shown, the stand 1 is welded by rectangular steel pipes, which includes horizontal steel pipes, vertical steel pipes and reinforcing pipes arranged between them. There are process holes and anchor bolt holes 1.1 at the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com