Follow-up press roll device controlled by air cylinders

A pressure roller device, cylinder control technology, used in general parts of printing machinery, printing, rotary printing machines and other directions, can solve the problem of not being able to meet the requirements of high-precision printing inspection, achieve compact and reasonable structure, ensure accurate positioning, save money effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

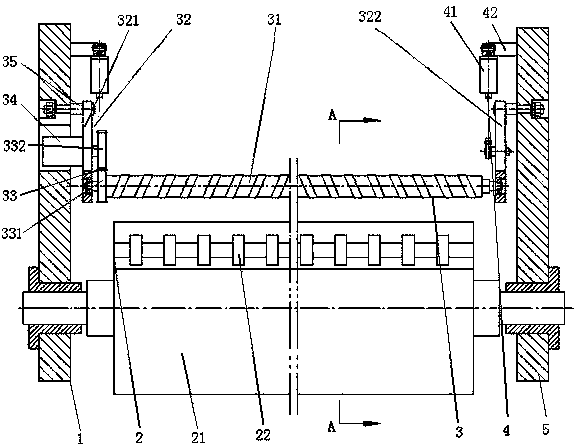

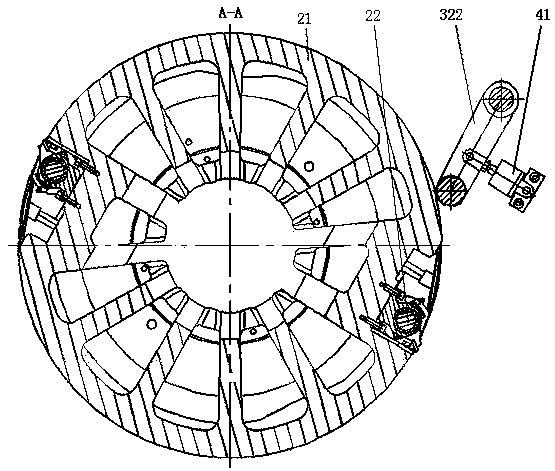

[0013] Refer to attached figure 1 , attached figure 2 , a cylinder-controlled follow-up roller device of the present invention, which is composed of wallboard I1, roller device 2, roller device 3, cylinder assembly 4, wallboard II5, and roller device 2 is supported on wallboard I1 by a support and on the wallboard II5, the pressure roller device 3 is arranged on the wallboard I1 and the wallboard II5, and is in contact with the roller device 2 through the cylinder assembly 4; The pressure roller presses the pressing mechanism of the paper; the described roller device 2 is made up of a cylinder body 21 and a paper nip mechanism 22, and the cylinder body 21 is provided with a paper nip mechanism 22; the described pressure roller device 3 consists of a pressure roller 31. The connecting plate assembly 32, the gear pair 33, the motor 34, and the connecting shaft 35 are composed. The pressure roller 31 is a rubber roller body with opposite helical directions in the left and right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com