Grinding tool correction mechanism driven by servo motor

A technology of servo motor and abrasive tool, which is applied in the direction of grinding machine parts, workpiece feed movement control, and manufacturing tools, etc., can solve the problems of reducing machining accuracy, abrasive tool loss, and different widths, and improve work efficiency. , The effect of reducing production costs and simplifying process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

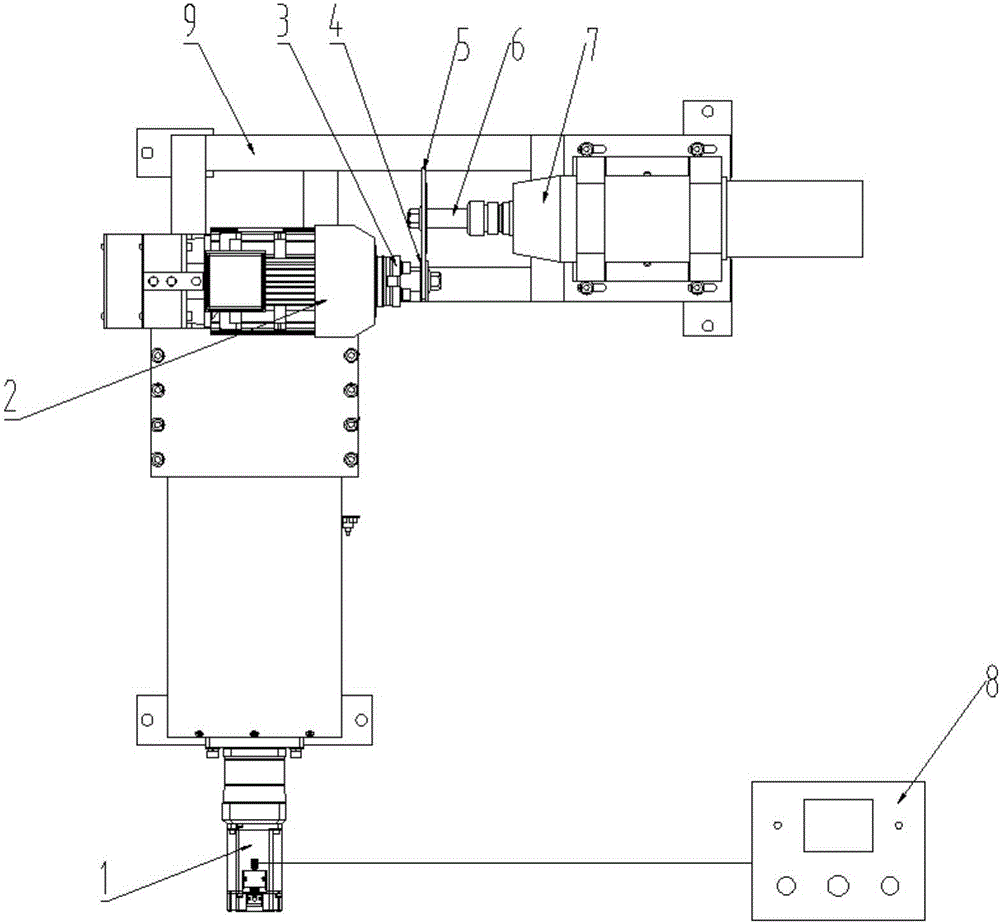

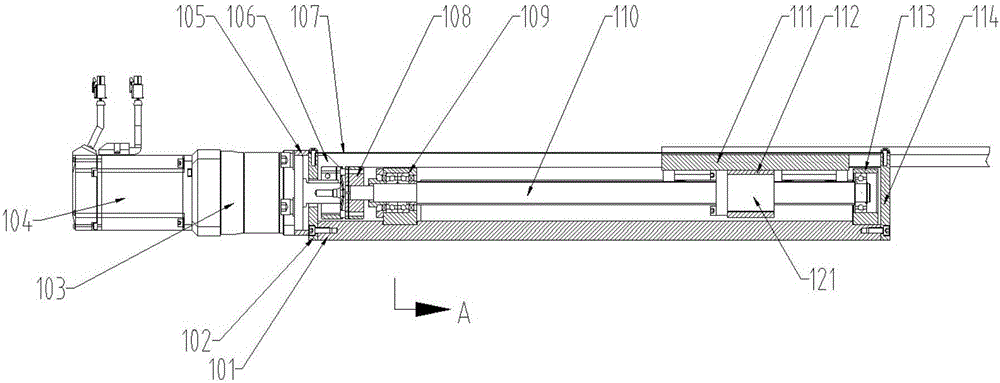

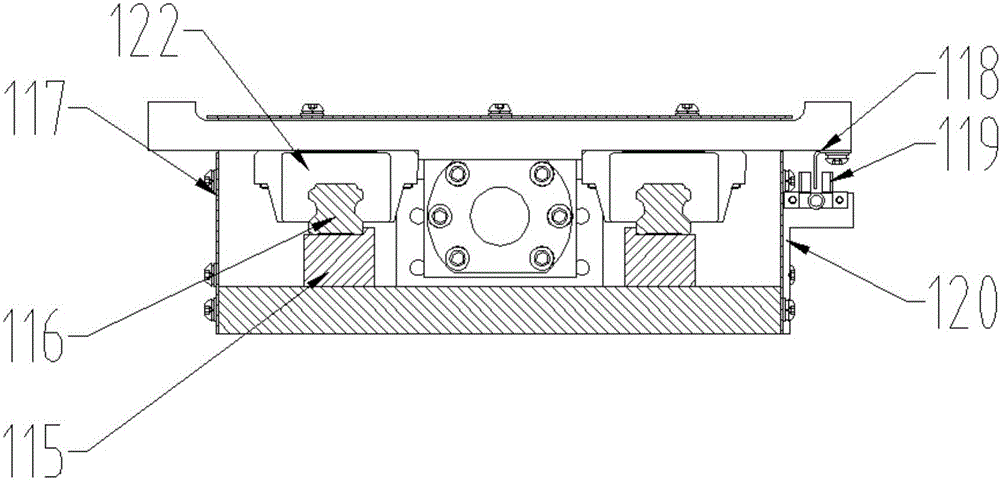

[0025] figure 1 It is a top view structural schematic diagram of a grinding tool correction device in a preferred solution of the present invention. figure 2 It is a partial cross-sectional structural schematic diagram of the front view of the two-way correction module of the abrasive tool. image 3 for figure 2 Schematic diagram of a partial cross-sectional structure along the A direction. From figure 1 It can be seen from the figure that the abrasive tool correction mechanism is mainly composed of a two-way abrasive tool correction module 1, a power device 2, a mounting flange 3, an abrasive tool grinding wheel 4, a servo controller 8 and a frame body 9. Among them, the two-way correction module 1 of the abrasive tool includes a large installation plate 101, an end vertical plate 102, a reducer 103, a servo motor 104, a servo motor mounting plate 105, a triangular rib plate 106, an upper cover plate 107, an elastic coupling 108, Ball screw 110, slider connecting plate ...

Embodiment 2

[0032] figure 2 It is a top structural schematic diagram of the mold correction device in another preferred solution of the present invention. The difference between this embodiment and embodiment 1 is that the mold used is a grinding rod, and the grinding machine 7 is a grinding rod machine. Abrasive grinding wheel 4 is a grinding rod grinding wheel. At the same time, the length direction of the support 9 is the same as the length direction of the grinding tool bidirectional correction module 1 (the two directions are perpendicular in Embodiment 1). Simultaneously, the grinding tool installation shaft 6 is not provided, and the grinding tool 5, that is, the grinding rod, is directly installed on the grinding tool machine 7 (ie, the grinding rod machine 7).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com