Beneficiation method and system for calcium or calcareous and siliceous phosphorite and application method of beneficiation system

A beneficiation method and phosphate rock technology are applied in the directions of chemical instruments and methods, wet separation, and process efficiency improvement, etc., and can solve the problems of low particle size of mineral apatite embedded, difficult monomer dissociation, and high beneficiation cost. Achieve significant energy-saving effect, high heat transfer speed and high equipment efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

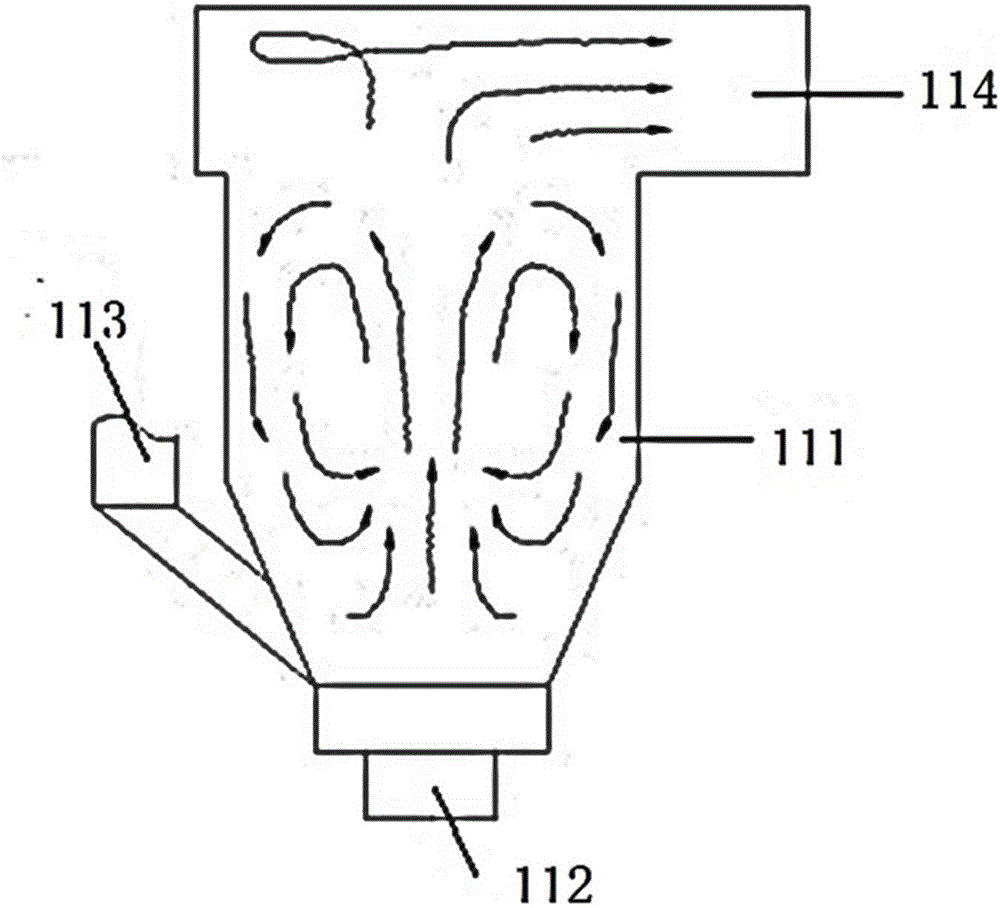

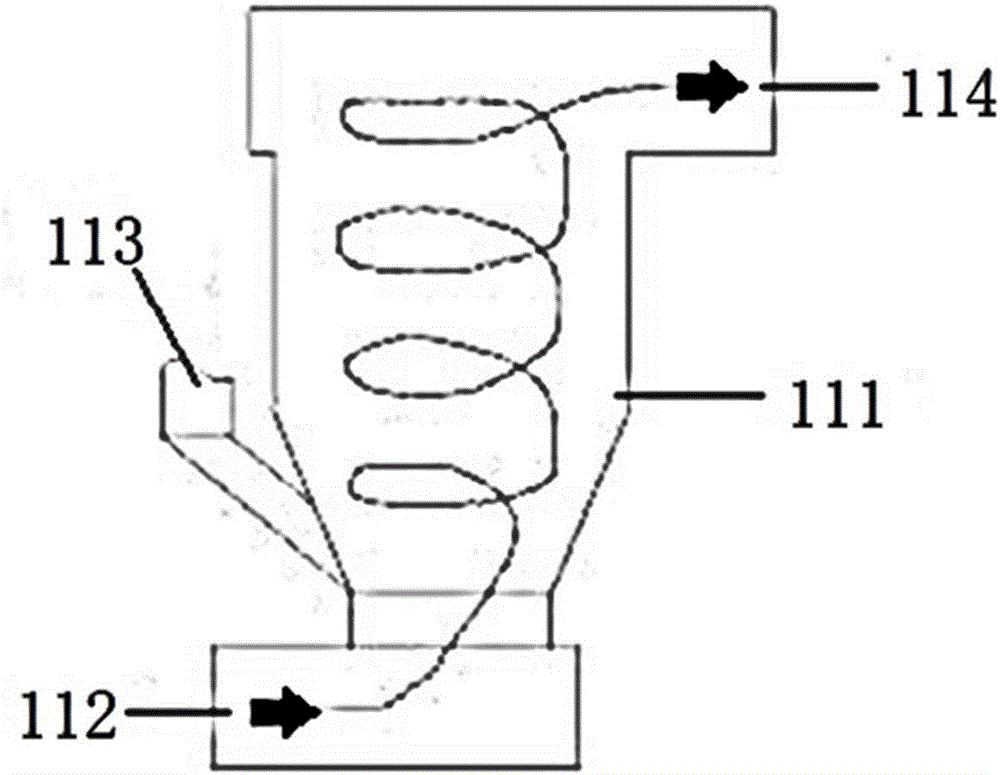

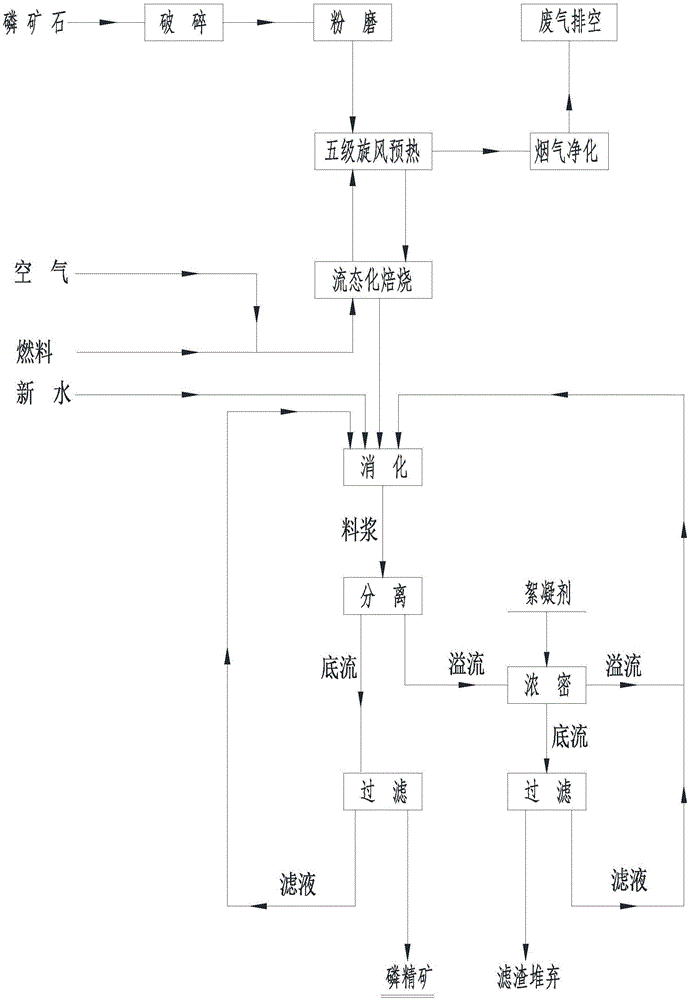

[0079] a kind of like image 3 The beneficiation system for calcium or calcium-siliceous low-magnesium phosphate rock of the present invention shown in the present invention includes a fluidized roasting system, a tail gas purification system and a digestion and separation system; the fluidized roasting system includes fluidized roasting and decomposition Furnace 1, feeding assembly, suspension preheating assembly, gas supply assembly and combustion assembly; fluidized roasting and decomposition furnace 1 includes a furnace body 111, and the lower part of the furnace body 111 is provided with an air inlet 112 and a feed inlet 113 The air inlet 112 is connected with the combustion assembly, the gas supply assembly is connected with the combustion assembly, and the feed port 113 is connected with the discharge port of the suspension preheating assembly; 114 communicates with the air inlet of the suspension preheating assembly; the air outlet of the suspension preheating assembly...

Embodiment 2

[0093] a kind of like Figure 5 Shown is a beneficiation system for calcium or calcium siliceous phosphate rock containing high magnesium of the present invention, which includes a fluidized roasting system, a tail gas purification system, a digestion and separation system, and a carbonization pyrolysis system.

[0094] The fluidized roasting system in this embodiment includes a fluidized roasting and calcining furnace 1, a feed assembly, a suspension preheating assembly, an air supply assembly and a combustion assembly; the fluidized roasting and calcining furnace 1 includes a furnace body 111 , the lower part of the furnace body 111 is provided with an air inlet 112 and a feed port 113; the air inlet 112 is connected with the combustion assembly, the air supply assembly is connected with the combustion assembly, and the feed port 113 is connected with the discharge port of the suspension preheating assembly The upper part of the furnace body 111 is provided with an air outle...

Embodiment 3

[0115] a kind of like Figure 7 Shown is a beneficiation system for calcium or calcium siliceous phosphate rock containing high magnesium of the present invention, which includes a fluidized roasting system, a tail gas purification system, a digestion and separation system, and a carbonization pyrolysis system.

[0116] The fluidized roasting system in this embodiment includes a fluidized roasting and calcining furnace 1, a feed assembly, a suspension preheating assembly, an air supply assembly and a combustion assembly; the fluidized roasting and calcining furnace 1 includes a furnace body 111 , the lower part of the furnace body 111 is provided with an air inlet 112 and a feed port 113; the air inlet 112 is connected with the combustion assembly, the air supply assembly is connected with the combustion assembly, and the feed port 113 is connected with the discharge port of the suspension preheating assembly The upper part of the furnace body 111 is provided with an air outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com