Process for treating tail gases of methyl ethyl ketone unit

A methyl ethyl ketone and tail gas technology, applied in membrane, membrane technology, dispersed particle separation and other directions, can solve the problems of complex process and high production cost, and achieve the effects of good selectivity, low operating cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

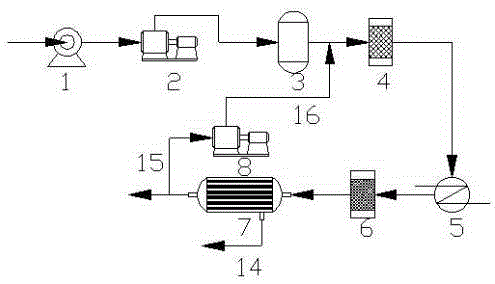

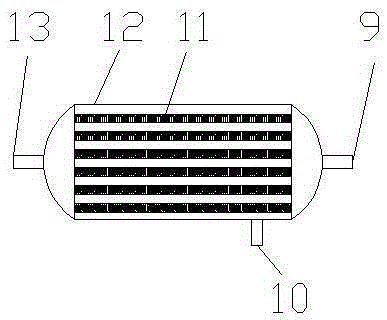

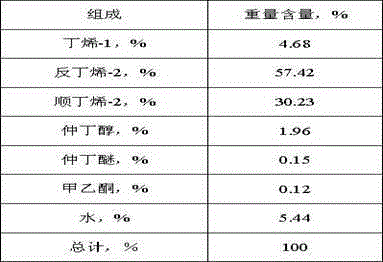

[0033] Using the tail gas of the methyl ethyl ketone plant listed in Table 2 as the raw material, the solid particles and water carried in the tail gas are initially removed by the gas centrifuge, and then pressurized to 0.5MPa by the gas booster and then enters the high-pressure storage tank; further dehydration by the activated carbon filter Dust removal, the fine dust content in the treated exhaust gas is 0.008mg / Nm 3 , the water content is 0.8PPm, and then the temperature of the methyl ethyl ketone tail gas reaches 50°C after heat exchange by the shell and tube countercurrent heat exchanger. Permeate gas containing n-butene and retentate gas containing alcohol, ether, methyl ethyl ketone and moisture. The permeate gas is sent to the methyl ethyl ketone plant as the raw material for the synthesis of sec-butanol; the retentate gas is adsorbed by different adsorbents to further remove the alcohol, ether, methyl ethyl ketone and moisture in it, and then returns to the membrane...

Embodiment 2

[0035] According to the method of Example 1, the gas is only pressurized to 1.0MPa and then enters the high-pressure storage tank; the activated carbon filter is further dehydrated and dust-removed, and the dust content in the treated tail gas is 0.009mg / Nm 3 , the water content is 0.8PPm, after the heat exchange by the heat exchanger, the temperature of the methyl ethyl ketone tail gas reaches 80°C, and enters the membrane separator under the conditions of a pressure of 1.0MPa and an inlet velocity of 5m / s, and the permeate rich in n-butene is separated gas and retentate gas containing alcohol, ether, methyl ethyl ketone and moisture. The permeate gas is sent to the methyl ethyl ketone plant as the raw material for the synthesis of sec-butanol; the retentate gas is adsorbed by different adsorbents to further remove the alcohol, ether, methyl ethyl ketone and moisture in it, and then returns to the membrane separator for further purification after being pressurized as the reflu...

Embodiment 3

[0037] According to the method of Example 1, the gas is only pressurized to 0.8MPa and enters the high-pressure storage tank; the fine dust content in the exhaust gas is 0.01mg / Nm through a precision filter 3 , the water content of 1.0PPm into the membrane gas, after heat exchange by the heat exchanger, the temperature of the methyl ethyl ketone tail gas reaches 65°C, and enters the membrane separator under the conditions of a pressure of 0.8MPa and an inlet velocity of 2.0m / s, and separates the rich Permeate gas of n-butene and retentate gas containing alcohol, ether, methyl ethyl ketone and moisture. The permeate gas is sent to the methyl ethyl ketone plant as the raw material for the synthesis of sec-butanol; the retentate gas is adsorbed by different adsorbents to further remove the alcohol, ether, methyl ethyl ketone and moisture in it, and then returns to the membrane separator for further purification after being pressurized as the reflux gas; the other part The retenta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com