Multi-layer ice glazing method for frozen shrimp meat

An ice-coating, multi-layer technology, applied in the fields of preservation of meat/fish by freezing/cooling, food preservation, food science, etc., can solve the problems of tissue damage, reduce the amount of ice-coating, oxidation, etc., to control the growth of microorganisms Growth, muscle protein protection, protection against microbial contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

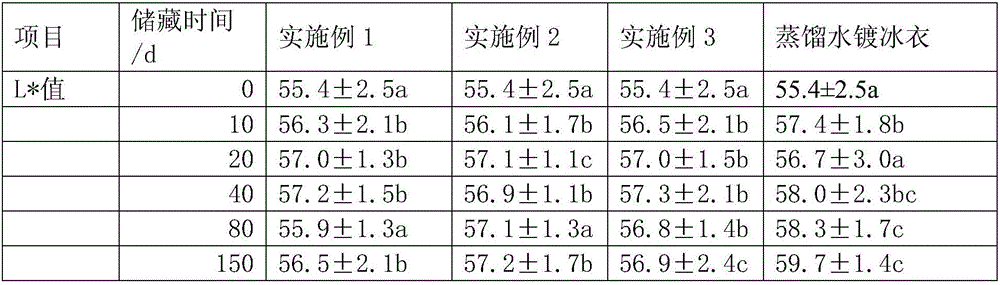

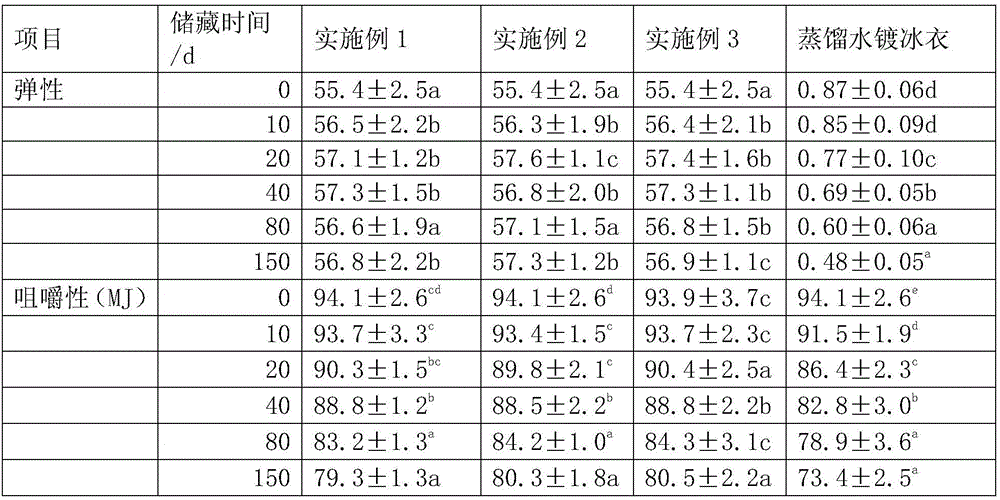

Examples

Embodiment 1

[0015] The ice coating method of the frozen shrimp of the present embodiment may further comprise the steps:

[0016] 1) Prepare the first layer of ice-coating solution: the aqueous solution contains 0.04% NaCl mass concentration, 1.0% alginate oligosaccharide mass concentration and 0.4% lactitol mass concentration;

[0017] 2) Plating the first layer of glazing: control the temperature of the first layer of glazing solution at 0.2°C, completely immerse the shrimps for 3 seconds, and then apply the first layer of glazing according to the conventional glazing operation;

[0018] 3) Prepare the second layer ice coat solution: the aqueous solution contains 0.05% of sodium citrate mass concentration, 0.01% of κ-carrageenan mass concentration, 0.08% of carboxymethyl cellulose mass concentration and 0.3% of L-sodium ascorbate mass concentration;

[0019] 4) Plating the second layer of glazing: control the temperature of the second layer of glazing solution at 1.2°C, immerse the shri...

Embodiment 2

[0022] The ice coating method of the frozen shrimp of the present embodiment may further comprise the steps:

[0023] 1) Prepare the first layer of ice-coating solution: the aqueous solution contains 0.06% NaCl mass concentration, 0.5% alginate oligosaccharide mass concentration and 0.8% lactitol mass concentration;

[0024] 2) Plating the first layer of glazing: control the temperature of the first layer of glazing solution at 0.6°C, completely immerse the shrimps for 5 seconds, and then apply the first layer of glazing according to the conventional glazing operation;

[0025] 3) Prepare the second layer ice coat solution: the aqueous solution contains 0.07% of sodium citrate mass concentration, 0.025% of κ-carrageenan mass concentration, 0.065% of carboxymethyl cellulose mass concentration and 0.2% of L-sodium ascorbate mass concentration;

[0026] 4) Plating the second layer of glazing: control the temperature of the second layer of glazing solution at 0.8°C, immerse the sh...

Embodiment 3

[0029] The ice coating method of the frozen shrimp of the present embodiment may further comprise the steps:

[0030] 1) Prepare the first layer of ice-coating solution: the aqueous solution contains 0.08% NaCl mass concentration, 0.8% alginate oligosaccharide mass concentration and 0.6% lactitol mass concentration;

[0031] 2) Plating the first layer of glazing: control the temperature of the first layer of glazing solution at 0.8°C, completely immerse the shrimps for 7 seconds, and then apply the first layer of glazing according to the conventional glazing operation;

[0032] 3) Prepare the second layer ice coat solution: the aqueous solution contains 0.09% of sodium citrate mass concentration, 0.04% of κ-carrageenan mass concentration, 0.05% of carboxymethyl cellulose mass concentration and 0.1% of sodium L-ascorbate mass concentration;

[0033] 4) Plating the second layer of glazing: control the temperature of the second layer of glazing solution at 0.6°C, immerse the shri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chewiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com