Refrigerator oil composition, and refrigeration device

A technology of refrigerating machine oil and composition, which is applied in the direction of lubricating composition, refrigerating machine, refrigerating components, etc., which can solve the problems of refrigerating device life and refrigerating efficiency reduction, and achieve the effect of excellent thermal stability and excellent compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

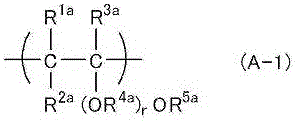

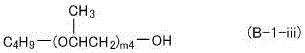

Method used

Image

Examples

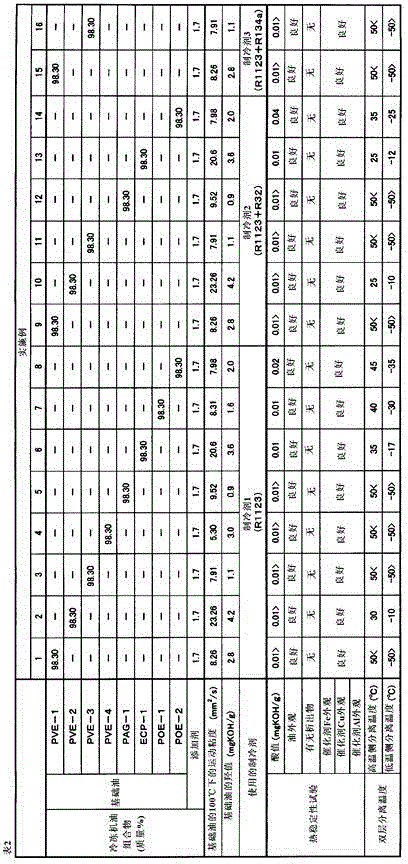

Embodiment 1~16 and comparative example 1~14

[0355] Refrigerator oil compositions with compositions shown in Tables 2 and 3 were prepared, mixed with the refrigerants described in the tables, and the thermal stability and double-layer separation temperature of the refrigerator oil compositions were measured and evaluated by the methods shown below. The results are shown in Tables 2 and 3.

[0356] (1) Thermal stability (moisture mixing sealing test)

[0357] The thermal stability of the refrigerating machine oil composition was evaluated by water mixing and sealing test.

[0358] Specifically, 30 g of the refrigerating machine oil compositions prepared in Examples and Comparative Examples, 30 g of the refrigerants described in Tables 2 and 3, and water in an amount such that the water content rate becomes 500 ppm were added to the glass tube, and filled with iron (Fe ), copper (Cu), aluminum (Al) metal catalysts and seal the tube, and keep it for 14 days in an environment with a pressure of 0.7kPa and a temperature of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com