Starting structure set and method of asynchronous starting permanent-magnet synchronous motor

A technology of asynchronous starting and permanent magnet synchronization, applied in the direction of starting devices, etc., can solve the problems of permanent magnet loss of magnetism, potential safety hazards, large space occupation, etc., and achieve the effect of reducing the wire diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

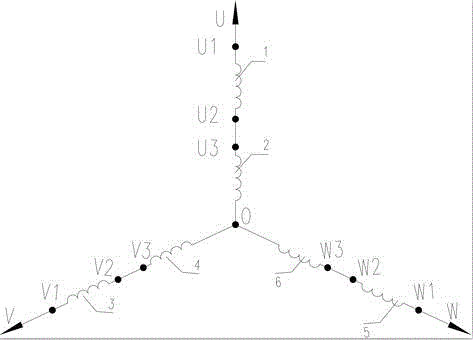

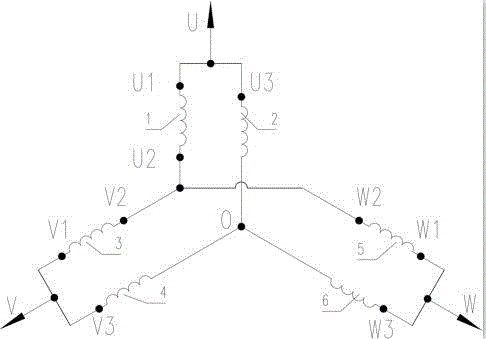

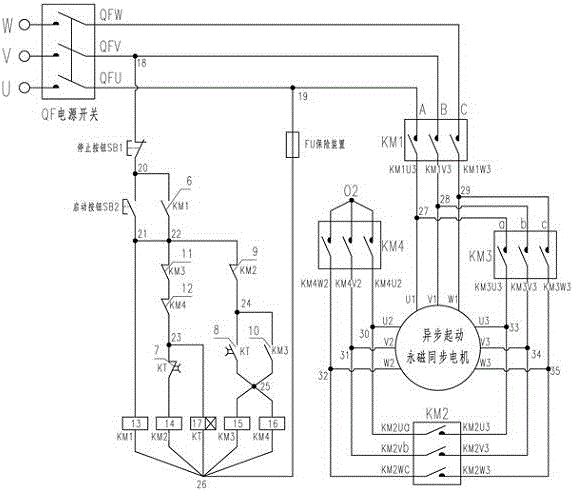

[0010] This technical solution is a three-step star-shaped winding connection method for asynchronously starting a permanent magnet synchronous motor with a low current speed and a stable speed-up start-up operation method. The first step of starting the motor winding is to use figure 1 The number of turns of the star-phase winding is twice that of the star-connection phase winding during operation. The cross-sectional area of the star-connection phase winding at start-up is half of that of the star-connection phase winding during operation. When the speed reaches 200~300 rpm, the control system image 3 Under the action of the asynchronous starting permanent magnet synchronous motor, the working winding switches to the second step state. figure 2 , the number of turns of the starting phase winding of star connection is half of that of the star connection phase winding of the first step, and the cross-sectional area of the star connection phase winding is twice the cross-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com