Three-phase iron core-type wireless energy transfer-used radial rotary converter

A technology of wireless energy transmission and rotation conversion, which is applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, electric components, etc. It can solve problems such as powder flying off, lower transmission efficiency, and heavy maintenance workload. Achieve the effects of reducing no-load current and no-load loss, improving transmission efficiency, and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

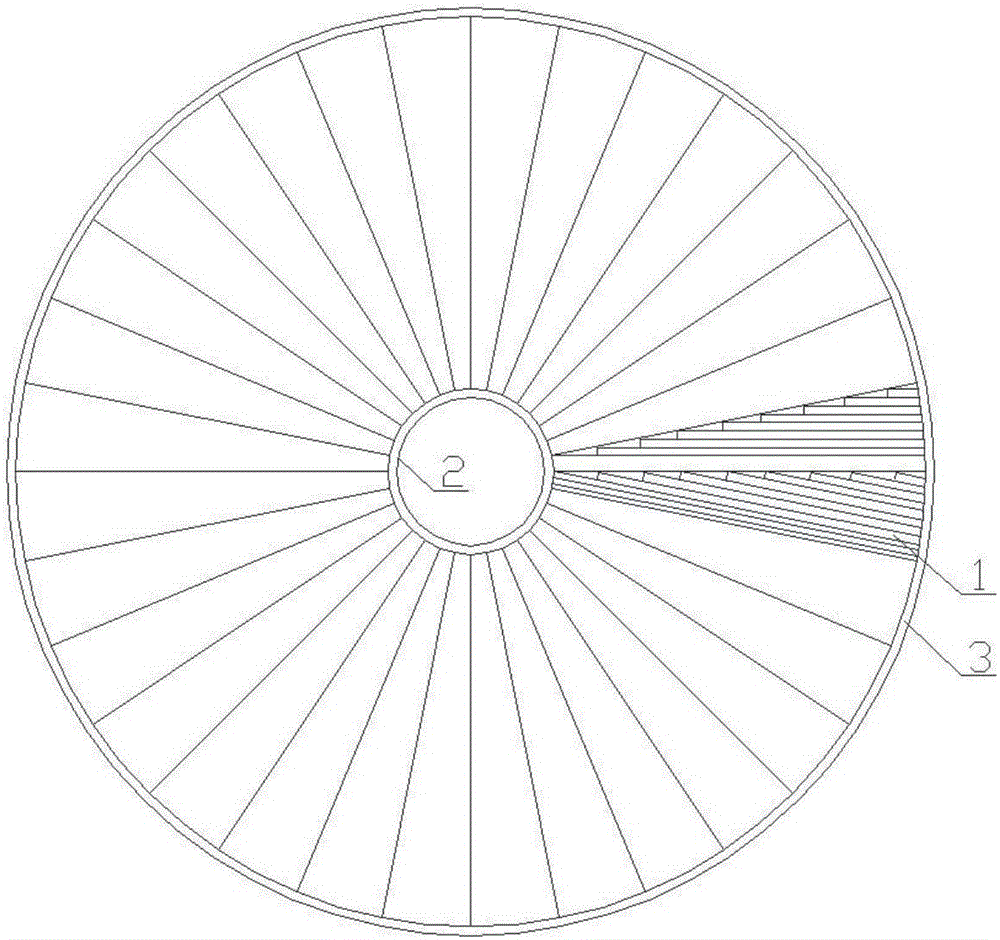

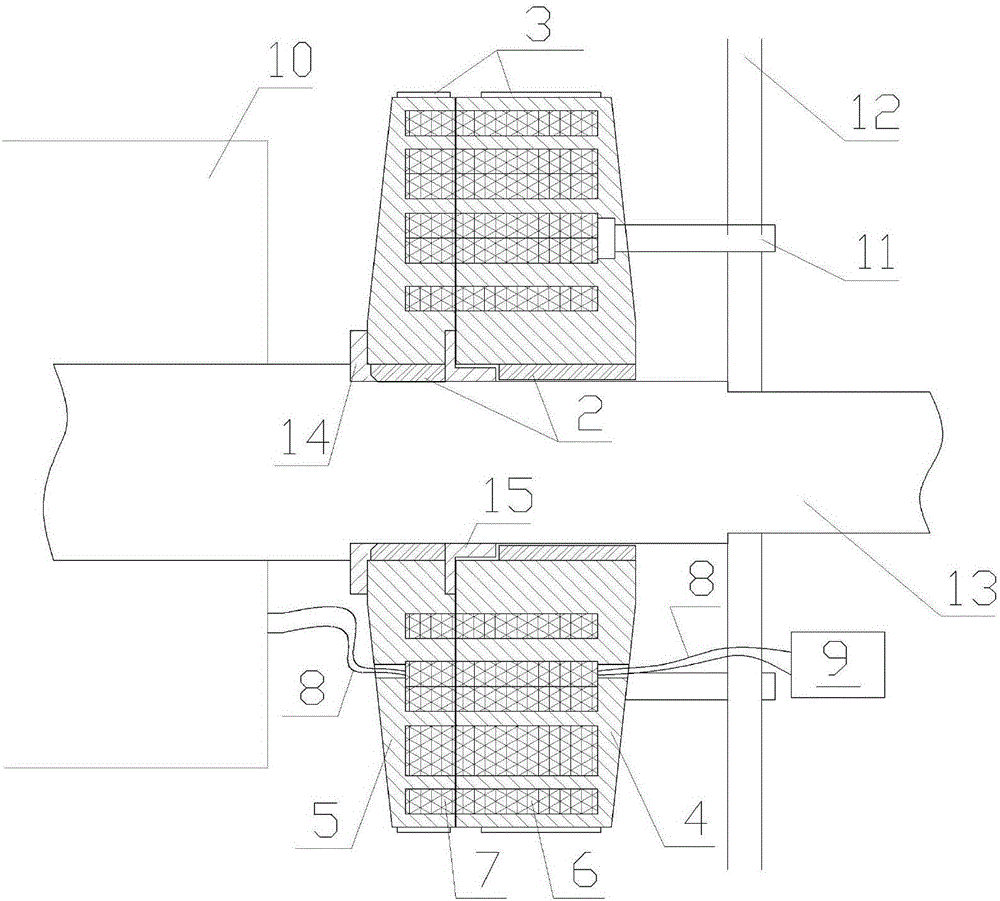

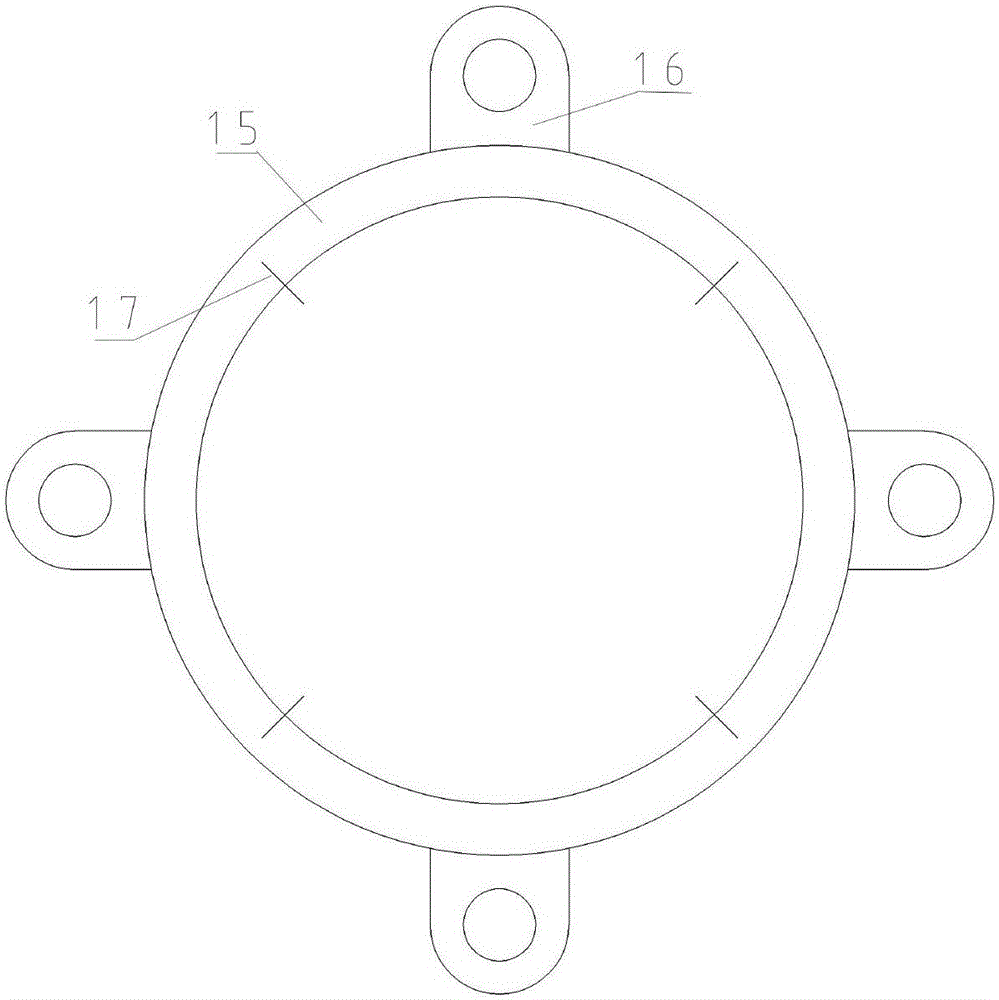

[0021] A three-phase core type radial rotary converter for wireless energy transmission, comprising a stator core 4, a rotor core 5, a motor shaft 13, lead wires 8, a power supply 9, and a rotor coil 10, see figure 1 , the section of the stator core and the rotor core are divided into several sectors on the circumference, and each sector is made of electrical steel strips 1 of equal length into radial main-level sheets, and each sector is composed of multiple electrician strips of decreasing size. The steel strip is filled, and the inner diameter side on the iron core of each electrical strip adopts copper sleeve 2 to support, and the outer diameter side on the iron core of each electrical strip adopts a shrinkable fastening band (in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com