An identification chip and its manufacturing method

A production method and chip technology, which is applied in the field of identification chips, can solve the problems of difficult identification of different chip chip electrodes, achieve the effects of reducing scrap rate and production cost, increasing brand recognition, improving chip identification rate and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Such as Figure 1-13 Shown, the present invention provides a kind of manufacturing method of LED identification chip, and manufacturing method comprises the following steps at least:

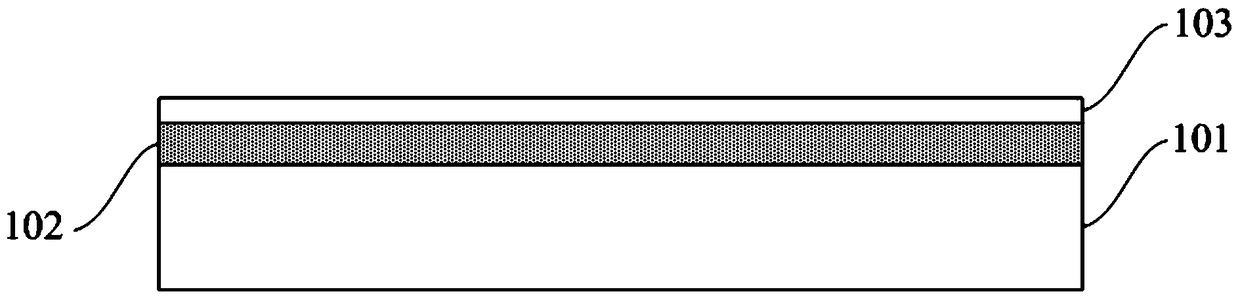

[0036] Such as figure 1 As shown, step S1 is first performed to provide a growth substrate 101 and form a light-emitting epitaxial layer 102 on the upper surface of the growth substrate 101 . In this embodiment, the growth substrate 101 can be sapphire (Al 2 o 3 ), the light-emitting epitaxial layer 102 includes an N-GaN light-emitting epitaxial layer. Then step S2 is executed.

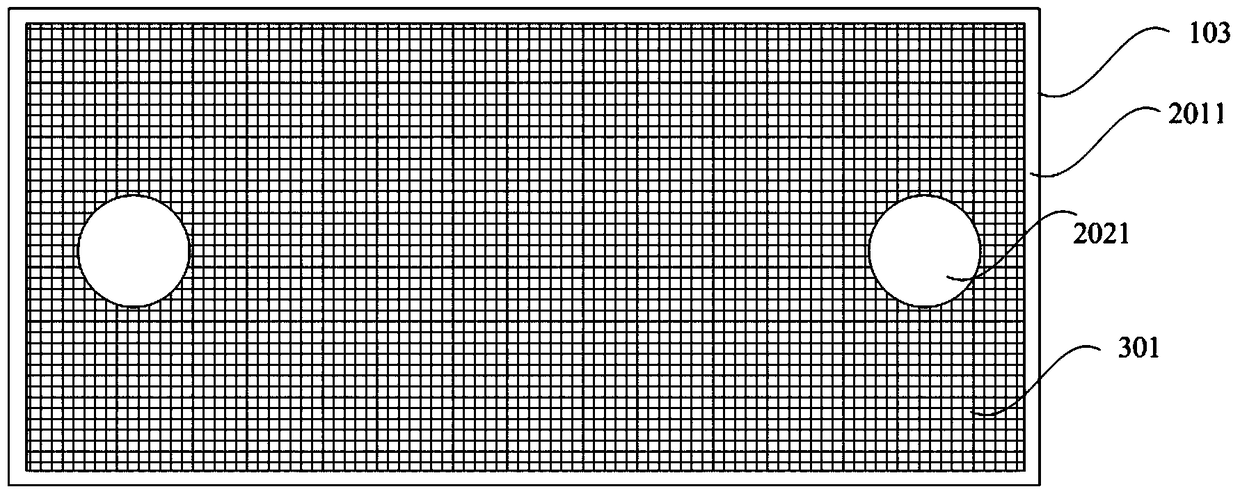

[0037] Such as figure 1 with figure 2 As shown, in step S2 , a transparent conductive layer 103 is formed on the upper surface of the light emitting epitaxial layer 102 . First, if figure 1 As shown, a transparent conductive layer 103 is formed on the surface of the light-emitting epitaxial layer 102 by evaporation or sputtering. Then, a photoresist layer 301 is formed on the transparent conductive la...

Embodiment 2

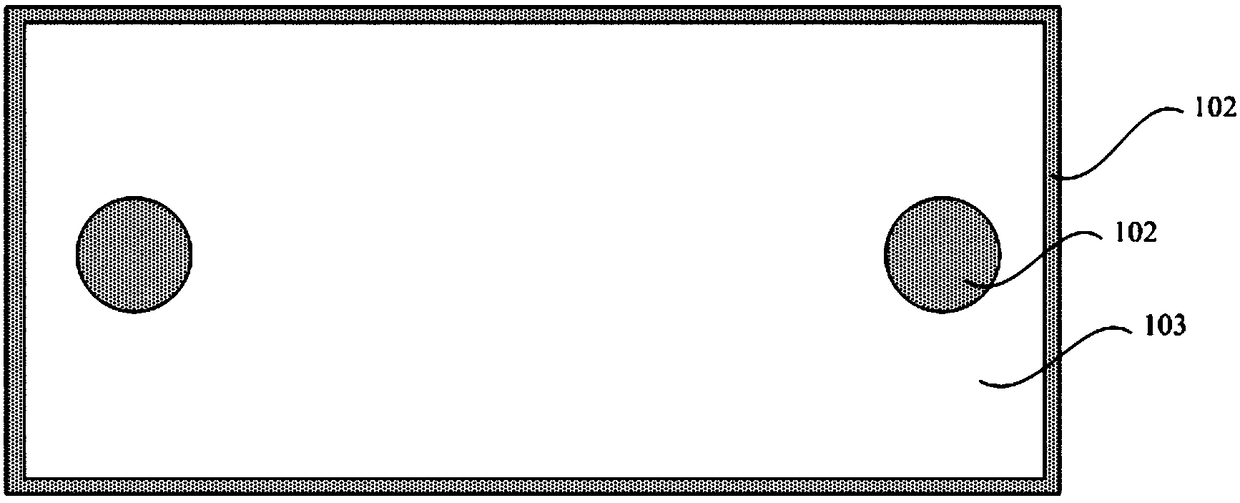

[0047] The present invention also provides an identification chip, such as Figure 14 As shown, the identification chip 1 includes: a growth substrate 101 , a light-emitting epitaxial layer 102 , a transparent conductive layer 103 , a mirror layer 104 , a barrier layer 105 , an N electrode diffusion layer 106 , a passivation layer 107 , and an electrode 108 .

[0048] For better understanding, please refer to Figure 1 to Figure 14 , as shown in the figure, the identification chip contains:

[0049] Growth substrate 101, in the present embodiment, growth substrate 101 can be sapphire (Al 2 o 3 ), silicon (Si) or silicon carbide (SiC).

[0050] The light emitting epitaxial layer 102 is formed on the upper surface of the growth substrate 101 . In this embodiment, the light emitting epitaxial layer 102 includes an N-GaN light emitting epitaxial layer. The light-emitting epitaxial layer 102 has a first scribe region 2011 and a first N hole region 2021 , at least one of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com