Assembling and adjusting system and method for multilayer nested X-ray focusing optical device

An X-ray and optical technology, applied in the field of X-ray optics, can solve the problems of large errors in the assembly process and unsatisfactory accuracy, and achieve the effect of convenient assembly and adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

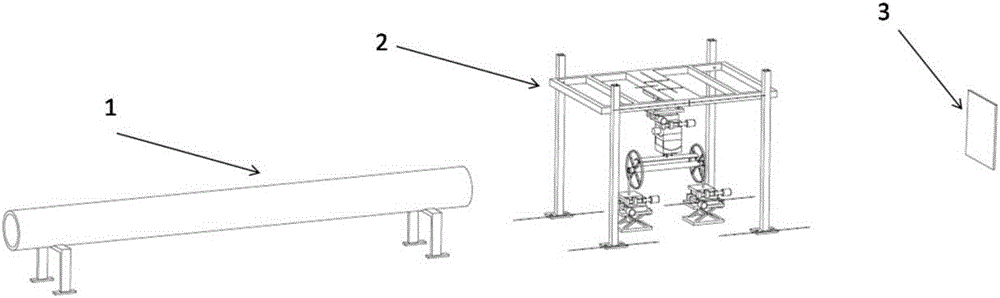

[0050] The multi-layer nested X-ray focusing optics assembly system provided by the present invention is as follows: figure 1 As shown, it includes a light source system 1, a main adjustment system 2 and a receiving screen 3 arranged in sequence, and the light source system 1, the main adjustment system 2 and the receiving screen 3 are placed coaxially.

[0051] The light source system 1 is composed of a visible light source and a laser collimator. The visible light source generates green light with a wavelength of 550nm, which is converted into a visible parallel beam with an exit angle of less than 10μrad by the laser collimator, thereby providing a collimated light source for the entire assembly system.

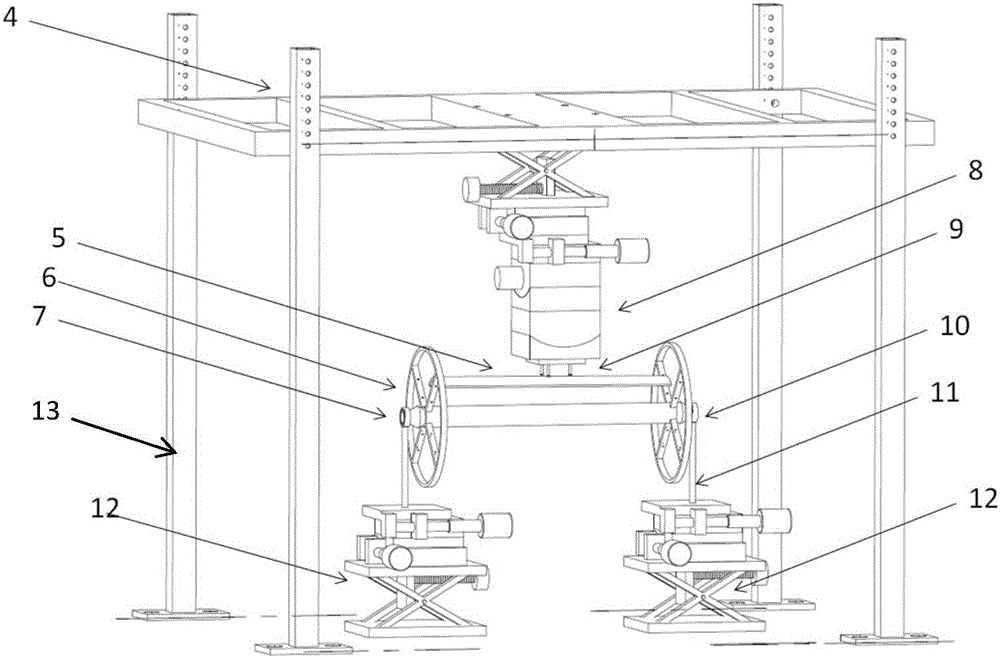

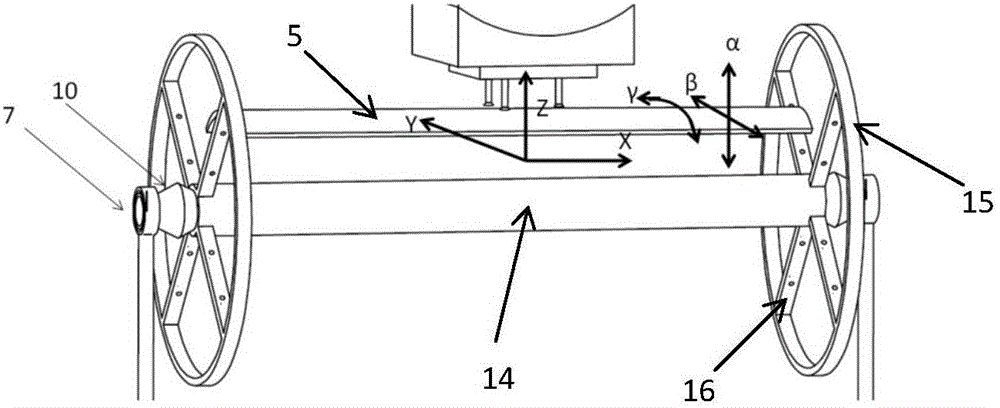

[0052] Adjust the structure of the main system 2 as figure 2 As shown, it includes an assembly frame, a six-dimensional adjustment device 8 , a glass connecting column 9 , a three-dimensional adjustment device group, a bearing 7 , a Morse taper cone 10 and a long rod 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com